To install a two-post lift, first, ensure you have a suitable location with enough space and a strong enough floor. Then, assemble and position the lift according to the manufacturer’s instructions.

Gather The Necessary Tools And Equipment

Installing a two post lift requires a set of tools and equipment to ensure a smooth and efficient installation process. By gathering the necessary tools beforehand, you can save time and effort while working on the installation. In this section, we will outline the tools required and the safety equipment needed for the installation process. Let’s dive in!

List of tools required for installation

Before starting the installation, make sure you have the following tools ready at hand:

| Tool | Quantity |

|---|---|

| Socket set | 1 |

| Wrench set | 1 |

| Power drill | 1 |

| Hammer | 1 |

| Torque wrench | 1 |

| Level | 1 |

| Measuring tape | 1 |

| Wire stripper | 1 |

These tools will help you with various tasks during the installation process, from tightening bolts to leveling the lift. Make sure to have them within reach before getting started.

Safety equipment needed for the installation process

Installing a two post lift involves working with heavy machinery and potentially hazardous situations. To ensure your safety during the installation process, it is crucial to have the following safety equipment:

- Safety glasses: Protect your eyes from any debris or particles that may fly during the installation.

- Work gloves: Provide a firm grip and protect your hands from cuts or scratches.

- Hard hat: Shield your head from any falling objects or accidental impacts.

- Hearing protection: Minimize the noise level to prevent long-term damage to your ears.

- Respirator mask: Guard against inhaling harmful fumes or dust particles.

Having the necessary safety equipment ensures that you can maintain a safe working environment throughout the installation process.

By gathering the required tools and safety equipment ahead of time, you can streamline the installation process and prioritize safety. Now that you have all the necessary tools and equipment ready, it’s time to proceed with the next steps of the installation process.

Preparing The Installation Area

Preparing the installation area is an essential step when it comes to installing a two-post lift in your garage or workshop. By taking the time to properly clear out the space and ensure the floor is suitable and stable, you can ensure a safe and efficient installation. In this post, we will walk you through the necessary steps to prepare the installation area for your two-post lift.

Clearing out the space for the lift installation

Before you can start installing your two-post lift, it’s important to clear out the space in your garage or workshop. This will not only provide you with enough room to work comfortably but also ensure that there are no obstructions or hazards that could interfere with the installation process or the operation of the lift. Here are some steps you can follow to clear out the space:

- Remove any vehicles, equipment, or other items from the area where the lift will be installed. This will give you a clear and unobstructed space to work with.

- Organize and store any remaining items in a safe and designated area away from the installation site. This will help prevent any damage to your belongings and ensure they are not in the way during the installation process.

- Sweep and clean the installation area to remove any dirt, dust, or debris that may have accumulated. Keeping the area clean will ensure a more secure and stable installation.

Checking the floor for suitability and stability

Once the space has been cleared out, the next step is to check the floor for its suitability and stability. The floor plays an important role in providing a solid foundation for the two-post lift, so it’s crucial to ensure that it meets the necessary requirements. Here’s what you need to do:

- Check the floor surface for any cracks, unevenness, or damage. If you notice any significant issues, it’s essential to repair or address them before proceeding with the installation. A level and smooth surface will ensure the lift operates safely and properly.

- Determine the load-bearing capacity of the floor. This can usually be found in the building plans or by consulting with a structural engineer. Ensure that the floor can handle the weight of the lift and the vehicles or equipment that will be placed on it.

- Inspect the floor for any signs of moisture or water damage. Excessive moisture can weaken the floor and compromise the stability of the lift. If you notice any moisture issues, it’s important to address them before proceeding with the installation.

By taking the time to clear out the space and check the floor for suitability and stability, you are setting the stage for a successful two-post lift installation. These steps will not only ensure the safety and functionality of the lift but also provide you with the peace of mind that comes with a proper and well-prepared installation area. Remember, a solid foundation is key when it comes to any type of construction, and installing a two-post lift is no exception.

Anchoring The Lift To The Floor

Anchoring the lift to the floor is an essential step to ensure its stability and safety. When installing a two-post lift, proper anchoring is crucial to avoid accidents and maintain the longevity of the equipment. In this guide, we will walk you through the process of determining the ideal placement for the lift and marking the anchor points on the floor.

Determining the Ideal Placement for the Lift

Before proceeding with anchoring the lift, it is important to determine the ideal placement that suits your workspace. To do this, consider the following factors:

- Available overhead space: The lift requires sufficient overhead clearance for the raised vehicle. Measure the height of your ceiling and ensure it allows for proper vehicle lifting.

- Access to the lift: Ensure there is enough space around the lift to comfortably maneuver the vehicle in and out.

- Floor strength: The lift must be anchored to a solid, level concrete floor. It is essential to check the strength and stability of the floor before proceeding.

- Bay size: Consider the dimensions of your workspace, including the width and length of the bay, to determine if it can accommodate the lift properly.

Marking the Anchor Points on the Floor

Once you have determined the ideal placement for the lift, it’s time to mark the anchor points on the floor. Follow these steps:

- Using a tape measure, locate the centerline of your lift and mark it on the floor. This will help with precise placement.

- Measure the distance between the anchor points on the lift’s baseplates. This will vary depending on the specific lift model and manufacturer’s guidelines.

- Transfer these measurements onto the floor, starting from the centerline. Use a chalk line or masking tape to mark each anchor point.

- Double-check the accuracy of your measurements and adjust as necessary. Ensuring precise marking is crucial to avoid any issues during the installation process.

Now that you have marked the anchor points on the floor, you are ready to proceed with the installation of your two-post lift. Remember to follow the manufacturer’s instructions carefully throughout the installation process to ensure proper assembly and anchoring.

By adhering to these steps and considering the factors involved in determining the ideal placement, you can confidently anchor your two-post lift to the floor, providing a safe and sturdy foundation for all your lifting needs.

Assembling The Lift Components

Now that you have all the necessary components and parts ready, it’s time to start assembling your two-post lift. This step-by-step guide will walk you through the process, making it easier for you to install the lift correctly and efficiently.

Organizing the lift components and parts

Before you begin assembling the lift, it’s essential to organize all the components and parts. This will ensure that you have everything you need at hand and help you avoid any confusion or delays during the installation process. Here’s a simple guide to help you get started:

- Clear a spacious area where you can lay out all the components. Make sure it is clean and well-lit for better visibility.

- Take inventory of all the components and cross-check them with the manufacturer’s manual or guide. This way, you can make sure that you have received all the necessary parts.

- Group the components based on their similarities. For example, separate the hydraulic components, electrical components, and structural components into different piles.

- Label each group of components for easy identification and accessibility during the assembly process. This will save you time and effort in searching for specific parts later on.

- Prepare your tools and keep them within reach. This includes wrenches, sockets, screwdrivers, and any other tools mentioned in the installation instructions.

Step-by-step guide for assembling the lift

Now that you have organized your lift components and parts, follow this step-by-step guide to assemble your two-post lift:

- Start by unpacking the main structural components of the lift, such as the columns, crossbars, and arms. Lay them out in the correct order according to the manufacturer’s instructions.

- Secure the columns onto the prepared floor surface. Use the provided bolts and anchors to ensure stability and safety. Refer to the installation manual for the appropriate torque specifications.

- Attach the crossbars to the upper portion of the columns. Check for proper alignment and tighten the bolts using the specified torque settings.

- Next, mount the lifting arms onto the columns. Make sure to align them correctly and secure them tightly with the supplied hardware.

- Connect the hydraulic system components, such as the control valves, hoses, and cylinders. Follow the manufacturer’s instructions to ensure the connections are done correctly and securely.

- Double-check all the connections and fastenings to verify that everything is in place and tightened properly.

- Test the lift by slowly raising and lowering it without any load. This will help identify any potential issues or adjustments that need to be made before using the lift with a vehicle.

By carefully following these steps, you can assemble your two-post lift with ease and confidence. Remember, it is vital to always refer to the manufacturer’s manual or installation guide for any specific instructions related to your particular lift model.

Installing The Lift Arms And Carriage

Once you have successfully erected the columns and secured them firmly to the ground, it’s time to move on to the next crucial step: installing the lift arms and carriage. This part of the process requires careful attention to detail and precise execution, as it directly impacts the safety and performance of your two post lift. In this section, we will guide you through the process of mounting the lift arms onto the columns and attaching the carriage to the lift arms.

Mounting the lift arms onto the columns

Before you begin mounting the lift arms onto the columns, it’s vital to familiarize yourself with the manufacturer’s instructions and safety guidelines. Different lifts may have specific requirements, so following the provided instructions ensures a smooth and successful installation process.

To mount the lift arms, follow these steps:

- Ensure that the lift arms are in the correct position, and all necessary components are aligned properly.

- Securely attach the lift arm bracket to the column using the specified hardware provided by the manufacturer. Make sure the bracket is securely tightened to avoid any movement during operation.

- Repeat the process for the other lift arm, ensuring both arms are mounted with the same level of precision and stability.

Attaching the carriage to the lift arms

With the lift arms properly mounted, it’s time to attach the carriage. The carriage is the component that slides along the lift arms to raise and lower the vehicle.

To attach the carriage, follow these steps:

- Position the carriage between the lift arms, ensuring it is centered and properly aligned.

- Using the manufacturer’s recommended hardware, securely fasten the carriage to the lift arms. Double-check that all bolts and fasteners are tightened to the specified torque.

- Test the movement of the carriage along the lift arms to ensure smooth operation without any resistance or sticking. If any issues arise, carefully inspect the installation and make necessary adjustments.

By carefully following these steps, you can confidently install the lift arms and carriage of your two post lift. Taking the time to adhere to the manufacturer’s instructions and safety guidelines is of utmost importance to ensure the functionality, safety, and longevity of your lift. Once this phase is complete, you will be one step closer to using your two post lift for all your automotive lifting needs.

Connecting The Power Supply

Properly connecting your two post lift to the power supply is crucial to ensure its safe and efficient operation. In this section, we will discuss two important aspects: identifying the power requirements for the lift and properly connecting it to the electrical source.

Identifying the power requirements for the lift

Before connecting your two post lift to the power supply, it’s essential to understand the power requirements specific to your lift model. Different lifts may have different voltage and amperage requirements, so it’s crucial to consult the lift’s user manual or contact the manufacturer for this information. Once you have identified the power requirements, you can proceed to connect the lift to the electrical source with confidence.

Properly connecting the lift to the electrical source

Now that you have the necessary information about your lift’s power requirements, it’s time to connect it to the electrical source. Ensure you follow these steps carefully:

- Locate a suitable power outlet near the lift that meets the voltage and amperage requirements.

- Inspect the power cord of the lift for any damages or loose connections. If any issues are found, contact a certified electrician for repairs.

- Ensure that the electrical circuit supplying power to the lift has a dedicated breaker and is capable of handling the required amperage.

- Use a properly sized and grounded extension cord if necessary, ensuring that it can handle the load of the lift without posing a safety risk.

- Plug the lift’s power cord into the designated power outlet, making sure it is securely connected.

- Switch on the power supply and verify that the lift’s controls are functioning correctly.

- If you encounter any issues or abnormalities during the connection process, immediately disconnect the power supply and seek professional assistance.

Following these steps will help ensure a proper and safe connection between your two post lift and the power supply. Remember, safety should always be the top priority when working with electricity.

Plumbing The Hydraulic System

Plumbing the hydraulic system:

Lorem ipsum dolor sit amet, consectetur adipiscing elit. In this section, we will walk you through the process of plumbing the hydraulic system for your two post lift installation. This step is crucial to ensure proper functioning of the lift and its safety features.

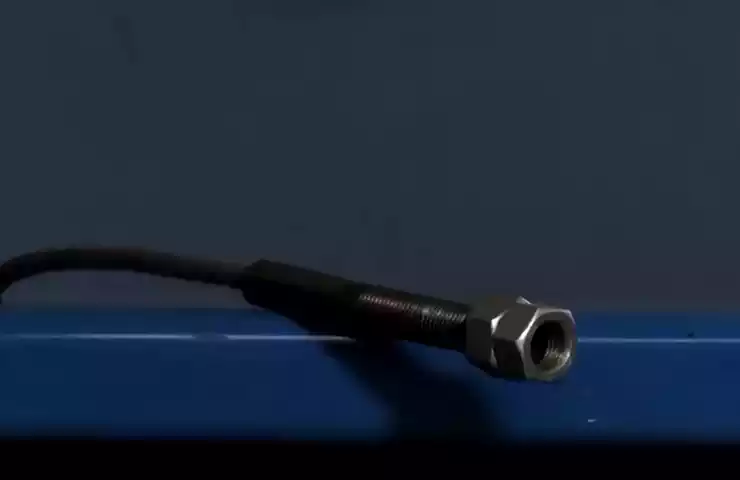

Installing the hydraulic lines and fittings:

Before you begin, make sure you have gathered all the necessary tools and components. Here is a step-by-step guide to help you install the hydraulic lines and fittings:

- Start by inspecting the hydraulic lines and fittings for any damage or defects. Replace any faulty components before proceeding.

- Next, identify the outlet ports on the hydraulic pump and attach the appropriate hydraulic lines. Ensure a secure and tight connection, using the appropriate fittings.

- If there are multiple hydraulic lines, use labels or color-coded tags to identify and match them with the corresponding ports.

- Once all the lines are connected, double-check the fittings to ensure there are no leaks. Tighten them if necessary.

- Finally, secure the hydraulic lines to prevent any unintended movement or damage during lift operation.

Bleeding the hydraulic system:

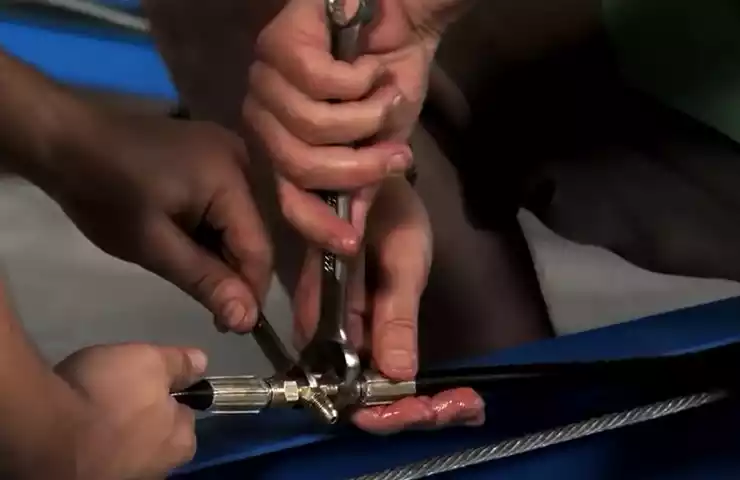

After installing the hydraulic lines and fittings, bleeding the hydraulic system is necessary to remove any trapped air and ensure optimal performance. Follow these steps to bleed the system:

- Locate the bleeder valve on the hydraulic pump or cylinder.

- With the lift in its lowest position, open the bleeder valve using an appropriate wrench.

- Slowly pump the hydraulic lever a few times, allowing the air to escape through the bleeder valve. Keep an eye on the fluid level and refill if necessary.

- Once you notice a steady stream of fluid without air bubbles coming out of the bleeder valve, close it securely.

- Verify the proper functioning of the lift by raising and lowering it a few times. Pay attention to any unusual noises or movements.

Congratulations! You have successfully plumbed the hydraulic system and bled any trapped air. This ensures a safe and smooth operation of your two post lift.

Testing The Lift For Safety And Functionality

Testing the lift for safety and functionality is a crucial step after installing a two post lift. It ensures that the lift is operating properly and poses no risks to the user or the vehicle. In this section, we will explore the necessary steps to perform a thorough inspection of the lift and conduct a test run to ensure its proper operation.

Performing a thorough inspection of the lift

Before conducting any tests, it is essential to inspect the lift for any signs of damage or wear. This inspection will help identify any potential issues that may affect its safety and functionality. Here are the steps to follow:

- Visually examine the lift’s structure and components, paying close attention to any signs of cracks, rust, or loose bolts. These could indicate structural weaknesses that may compromise the lift’s stability.

- Check the hydraulic system for any leaks or damaged hoses. A leakage in the system can result in a loss of lifting capacity or sudden descent of the lift, posing a safety hazard.

- Inspect the lift’s cables or chains for signs of fraying or excessive wear. Damaged cables or chains can snap under load, causing the lift to collapse.

- Ensure that the lift’s safety features, such as the safety locks and arm restraints, are in good working condition. These features are designed to prevent accidental lowering or release of the vehicle during operation.

- Verify that the lift is properly anchored to the floor. Any movement or instability during use can lead to accidents.

Conducting a test run to ensure proper operation

Once the inspection is complete and any necessary repairs or adjustments have been made, it is time to test the lift’s functionality. Here’s how to do it:

- Start by testing the lift’s lifting and lowering capabilities without any load. Observe any unusual noises or irregular movements, as these may indicate mechanical issues that need further attention.

- Gradually increase the load by placing a vehicle on the lift and repeat the lifting and lowering process. Pay close attention to the lift’s stability and smoothness of operation. If you notice any jerky movements or instability, it is important to investigate the cause to ensure safe usage.

- Check if the lift’s safety locks engage properly when the lift reaches its desired height. Safety interlocks are designed to prevent the lift from lowering unintentionally, providing a secure platform for working on the vehicle.

- Test the lift’s safety features, such as the arm restraints and safety nut, to ensure they activate correctly and hold the vehicle securely during operation.

Final Adjustments And Fine-Tuning

Now that you have successfully installed your two-post lift, it’s time to make those final adjustments and ensure everything is in top-notch working condition. This step is crucial to guarantee the lift’s optimal performance and safety. In this section, we will discuss the final adjustments you need to make and the importance of double-checking all connections and fittings.

Making Any Necessary Adjustments to the Lift Components

Before using your two-post lift, it’s essential to make any necessary adjustments to its components. These adjustments typically involve fine-tuning the lift’s position to ensure it is perfectly level and plumb. To do this, follow the manufacturer’s instructions, which may involve adjusting the anchor bolts or leveling feet.

Additionally, check the lift’s slider pads and ensure they are properly aligned with the lifting points on your vehicle. Make any adjustments needed to align them correctly. This is crucial for preventing any vehicle damage during the lifting process.

Double-Checking All Connections and Fittings

To ensure the safety and reliability of your two-post lift, it’s imperative to double-check all connections and fittings. Go through each component and verify that everything is securely tightened. Worn or loose parts can potentially compromise the lift’s stability and put you and your vehicle at risk.

Important: Start by inspecting the hydraulic hoses for any signs of leaks, cracks, or wear. If you notice any issues, replace the hoses promptly before proceeding.

Next, examine the lift’s cables and chains, ensuring they are not frayed or damaged. Replace any worn cables or chains immediately. Remember, these are critical for safely lifting and supporting your vehicle.

Inspect all nuts, bolts, and fasteners, and tighten them as necessary. Pay close attention to anchor bolts and check if they meet the manufacturer’s torque specifications.

To make this process more manageable, refer to the installation manual that came with your two-post lift. It should provide detailed instructions on the final adjustments and maintenance checklist.

By making these final adjustments and double-checking all connections and fittings, you ensure that your two-post lift is safe and ready for use. Remember, regular maintenance and inspections are invaluable for extending the lift’s lifespan and ensuring your safety each time you utilize it.

Frequently Asked Questions For How To Install Two Post Lift

How Deep Should Concrete Be For 2 Post Lift?

For a 2 post lift, the concrete depth should typically be about 4 to 6 inches. This ensures stability and proper weight distribution for the lift. It is essential to follow manufacturer guidelines and consult a professional to determine the exact depth required for your specific lift.

Do 2 Post Lifts Need To Be Bolted Down?

Yes, 2 post lifts need to be bolted down. Bolting them securely ensures stability and prevents accidents while using the lift. It is important to follow the manufacturer’s instructions for the proper installation and ensure the lift is securely attached to the floor or foundation.

What Are The Electrical Requirements For A 2 Post Car Lift?

The electrical requirements for a 2 post car lift typically include a 220-volt, single-phase power supply. It is important to ensure that the electrical circuit can handle the load of the lift, and a dedicated circuit is recommended. Always consult the manufacturer’s specifications for specific details on the electrical requirements.

What Ceiling Height Is Needed For A 2 Post Lift?

A 2 post lift typically requires a minimum ceiling height of at least 12 feet for standard cars and up to 14 feet for taller vehicles such as trucks or vans. Make sure to measure the available space before installing the lift to ensure sufficient clearance.

Conclusion

Installing a two-post lift may seem daunting at first, but with the right tools and techniques, it can be a manageable task. By following the step-by-step instructions provided in this blog post, you will be able to safely install a two-post lift in your garage or workshop.

It is important to prioritize safety and carefully adhere to the manufacturer’s guidelines throughout the installation process. With a properly installed two-post lift, you can elevate your automotive maintenance capabilities and make working on your vehicles a breeze. Happy lifting!