To install load resistors for LED lights, follow these steps: connect the resistor’s positive terminal to the positive wire of the LED light, and the negative terminal to the negative wire of the LED light.

What Are Load Resistors?

What are load resistors?

Load resistors are electrical components used in LED light installations to address a common issue known as hyperflashing. When LED lights are installed in place of traditional halogen or incandescent bulbs, they typically require less power to operate. This can disrupt the balance of the electrical circuit, causing the lights to flicker or flash rapidly. Load resistors help to stabilize the current flow and ensure proper function of the LED lights.

Definition and purpose of load resistors

A load resistor is a device that adds resistance to an electrical circuit. In the context of LED lights, load resistors are connected in parallel with the light bulbs to consume extra voltage and regulate the current flow. By doing so, they mimic the power draw of the original halogen or incandescent bulbs, eliminating the hyperflashing effect caused by the lower power consumption of LEDs.

The primary purpose of load resistors is to provide a sufficient load to the turn signal or brake light circuit, effectively fooling the vehicle’s electrical system into thinking that a regular bulb is in use. This prevents any error codes or warning messages from being triggered on the dashboard and ensures the LED lights function properly.

Examples of load resistors in LED lights

Load resistors are commonly used in various LED lighting applications where hyperflashing can occur. Some examples include:

- Turn signal lights: Load resistors are frequently installed in LED turn signal lights to prevent rapid flashing and ensure the indicators operate at the correct speed. They provide the necessary resistance to mimic the power draw of the original bulbs, allowing the turn signals to function reliably.

- Brake lights: LED brake lights often require load resistors to maintain the proper blinking rate and prevent hyperflashing. By adding resistance to the circuit, load resistors ensure the brake lights illuminate brightly without flickering or flashing at an abnormal speed when the brake pedal is activated.

- Reverse lights: Load resistors may also be necessary in certain LED reverse lights to achieve consistent illumination. Without load resistors, reverse lights can flicker or flash rapidly due to the lower power requirement of LEDs compared to traditional bulbs.

Why Are Load Resistors Necessary For Led Lights?

Installing LED lights is a great way to enhance the lighting in your vehicle or home. However, it’s important to note that LED lights have a lower power draw compared to traditional incandescent lights. This can cause a few issues when it comes to their installation. One common problem is the hyperflash effect that occurs when the LED lights blink too quickly. Another issue is the error message that may appear on your dashboard, indicating a failure in the lighting system. To avoid these problems and ensure a smooth and efficient installation, load resistors are necessary for LED lights.

Explanation of why load resistors are needed in LED light installations

Load resistors play a crucial role in LED light installations. LED lights have a significantly lower resistance compared to traditional incandescent lights. As a result, the vehicle’s electrical system detects this difference in resistance and assumes that there is a burnt-out bulb or a fault in the lighting system. This detection leads to two common problems that can be resolved by using load resistors.

Problems that can occur without load resistors

Without load resistors, the installation of LED lights can cause two significant issues:

- The hyperflash effect: When LED lights blink too quickly, it creates a hyperflash effect. This fast blinking can be visually distracting for both the driver and other road users. Load resistors solve this issue by increasing the electrical load, causing the LED lights to blink at a normal rate.

- The dashboard error message: Without load resistors, the vehicle’s electrical system may detect the lower electrical load of LED lights as a failure. This can trigger an error message on the dashboard or even cause the lights to not function properly. By using load resistors, the electrical load is increased to match the resistance of the original incandescent bulbs, preventing any error messages and ensuring the proper functioning of the lights.

By installing load resistors for LED lights, you can avoid these problems and enjoy a hassle-free lighting upgrade. Next, we’ll explore the step-by-step process of how to install load resistors for LED lights to ensure a successful installation.

Selecting The Right Load Resistor For Your Led Light Installation

Factors to Consider When Choosing a Load Resistor

When it comes to installing LED lights, it is crucial to ensure that your lighting system functions optimally. One essential component for a successful LED light installation is the load resistor. The load resistor helps to rectify potential issues such as hyperflashing and bulb-out warnings by mimicking the resistance of a standard incandescent bulb. However, selecting the right load resistor can be overwhelming if you do not know what factors to consider.

Before you go ahead and purchase a load resistor for your LED lights, there are a few key factors you should keep in mind. By taking these factors into consideration, you can ensure that you choose the most suitable load resistor for your specific LED light installation. Let’s take a closer look at these factors:

- LED Light Voltage: The first factor you should consider is the voltage of your LED lights. Load resistors come in different voltage ratings, so it is essential to choose one that matches the voltage of your LED lights. This ensures proper functioning and compatibility.

- LED Light Current: Another crucial factor to consider is the current draw of your LED lights. Load resistors have different current ratings, and it is important to select one that can handle the current requirements of your LED lights. This helps to prevent any overload or overheating issues.

- Mounting and Space Constraints: Consider the available space for installing the load resistor. Some load resistors are small and compact, making them easier to install in tight spaces. On the other hand, larger load resistors might require additional mounting hardware or modifications to fit properly.

- Build Quality and Durability: It is always advisable to choose load resistors from reputable brands that are known for their quality and durability. This ensures that the load resistor can withstand the demands of your LED light installation and provide long-lasting performance.

How to Calculate the Appropriate Load Resistor Value

To determine the appropriate load resistor value for your LED light installation, you need to perform a simple calculation. This calculation involves considering the resistance value of the load resistor and the wattage of your LED lights.

- Identify the wattage of your LED light bulbs. This information can usually be found on the packaging or product specifications.

- Consider the voltage of your LED lights. This information is crucial for calculating the correct resistance value.

- Calculate the resistance value using Ohm’s Law: R = (V^2) / P, where R is the resistance in ohms, V is the voltage in volts, and P is the power in watts. By rearranging the equation, you can solve for the resistance value.

By following this simple calculation, you can determine the appropriate load resistor value for your LED light installation. However, it is always recommended to consult the manufacturer’s instructions or seek professional advice to ensure accuracy.

Recommended Load Resistor Brands and Models

When it comes to choosing load resistors, there are several reputable brands and models that offer reliable performance and compatibility. Here are a few recommended brands and models:

| Brand | Model |

|---|---|

| Brand A | Model X |

| Brand B | Model Y |

| Brand C | Model Z |

These brands have gained a positive reputation for their quality load resistors that are designed to ensure seamless compatibility with various LED light installations.

In conclusion, selecting the right load resistor for your LED light installation is critical for optimal performance and to avoid potential issues. By considering factors such as voltage, current, mounting constraints, and choosing reputable brands, you can make an informed decision. Additionally, calculating the appropriate load resistor value using Ohm’s Law allows for a precise match. Remember to always consult the manufacturer’s instructions or seek professional advice for specific requirements and guidance.

Step-By-Step Guide To Installing Load Resistors For Led Lights

Installing load resistors for LED lights is an essential step to ensure the proper functioning of your lighting system. These resistors are designed to mimic the load of a traditional incandescent bulb and prevent issues such as hyperflashing or error codes. In this step-by-step guide, we will walk you through the process of installing load resistors for LED lights, from preparing the necessary tools and equipment to testing the functionality of the resistors.

Preparing the necessary tools and equipment

Before you begin the installation process, make sure you have the following tools and equipment ready:

- Load resistors

- Wire cutters and strippers

- Screwdriver

- Electrical tape

- Heat shrink tubing

- Heat gun or lighter

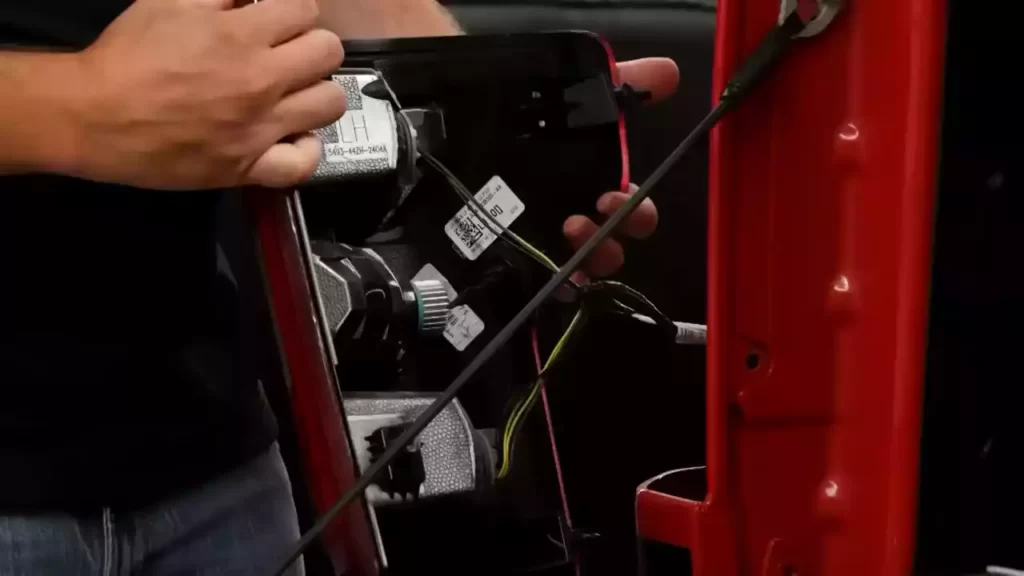

Locating the appropriate wiring connections for the load resistors

The next step is to locate the appropriate wiring connections for the load resistors. Using a wiring diagram or consulting the vehicle’s manual can help you identify the correct wires. In most cases, you will need to connect the load resistor to the turn signal or brake light circuit.

To locate the wiring connections:

- Locate the turn signal or brake light wiring harness near the bulb socket.

- Identify the positive and negative wires. The positive wire is usually colored with the corresponding turn signal or brake light color (e.g., green for the right turn signal).

- Use wire cutters to carefully cut the positive wire near the bulb socket. Leave enough wire length to work with.

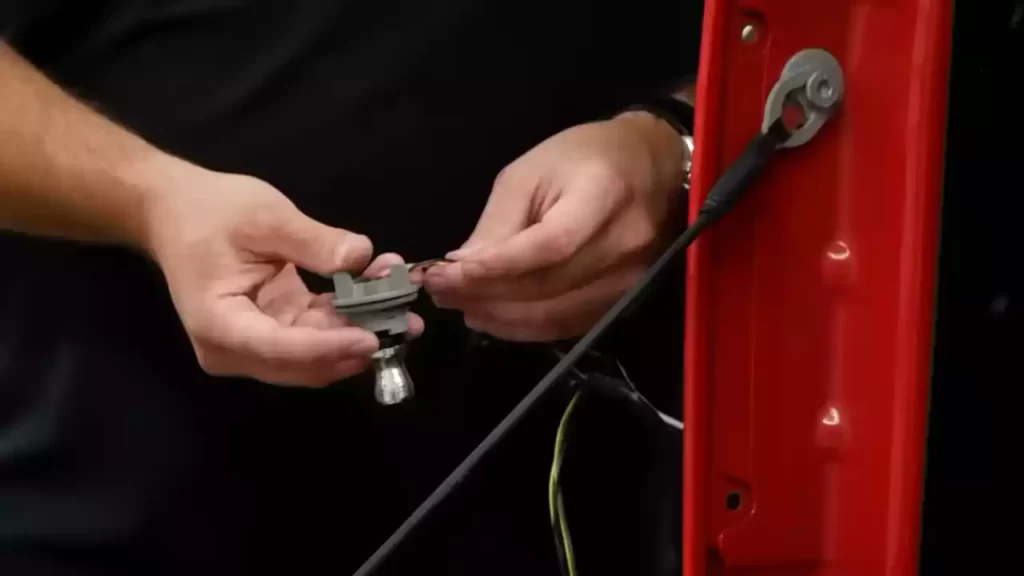

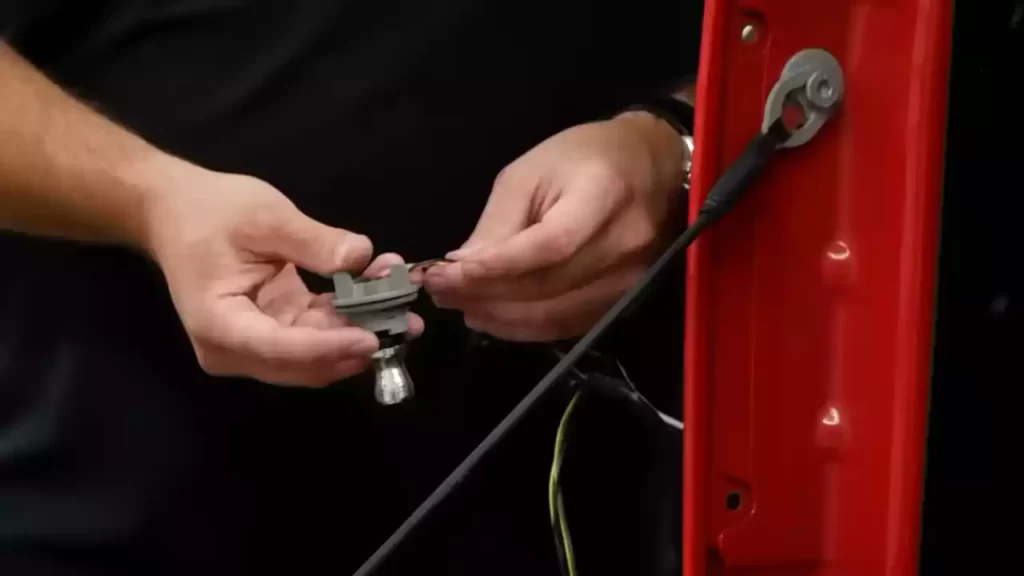

Properly connecting the load resistors to the LED lights

Now that you have located the wiring connections, it’s time to properly connect the load resistors to the LED lights. Follow these steps:

- Take one end of the load resistor and strip about 0.5 inches of insulation from the wire.

- Twist the exposed wire end of the load resistor with the positive wire that you cut earlier.

- Secure the connection by twisting a wire nut or using electrical tape.

- Repeat the process for the remaining load resistors and wiring connections.

- Once all connections are properly made, use electrical tape or heat shrink tubing to insulate the exposed wires.

Testing the functionality of the load resistors

After connecting the load resistors, it’s important to test their functionality to ensure they are working correctly. Follow these steps:

- Turn on the vehicle’s ignition and activate the turn signal or brake lights.

- Observe the LED lights to see if they are flashing at the correct rate or if there are any error codes.

- If the LED lights are not flashing correctly or there are error codes, double-check the connections and make sure the load resistors are properly installed.

- Make any necessary adjustments or reconnections if needed.

By following this step-by-step guide, you can easily install load resistors for LED lights and ensure a smooth and functional lighting system. Remember to always consult the vehicle’s manual or wiring diagram if you have any concerns or doubts about the installation process.

Troubleshooting Common Issues With Load Resistors Installation

Installing load resistors for LED lights can be a simple and effective way to ensure that your lights function properly. However, like any installation process, there can be a few common issues that may arise. Identifying these problems and knowing how to troubleshoot them can save you time and frustration. In this section, we will discuss some common problems that may occur during load resistor installation and provide you with tips for troubleshooting and fixing these issues.

Identifying common problems that may occur during installation

During the installation of load resistors for LED lights, you may come across a few common issues. Here are some of the problems you may encounter:

- Incorrect wiring connections: One of the most common problems is incorrect wiring connections. This can happen when the load resistor is not properly connected to the LED light or the vehicle’s electrical system. It is important to double-check the wiring connections to ensure they are correct.

- Overheating: Another common issue is overheating. Load resistors generate heat as they consume excess power to mimic the load of a standard bulb. If the resistor gets too hot, it can become damaged or even pose a fire hazard. It is important to monitor the temperature of the load resistor during operation.

- Failed lights: If the LED lights are not working after installing the load resistors, it could be due to a faulty resistor or a wiring issue. Checking the load resistor and the wiring connections can help identify the cause of the problem.

Troubleshooting tips for fixing load resistor installation issues

Now that we have identified some common problems during load resistor installation, let’s discuss some troubleshooting tips:

| Problem | Troubleshooting Tip |

|---|---|

| Incorrect wiring connections | Double-check the wiring connections and ensure that they are connected properly. If necessary, refer to the installation instructions provided with the load resistor. |

| Overheating | Monitor the temperature of the load resistor during operation. If it becomes too hot, consider adding additional cooling measures, such as heat sinks or fans, to prevent overheating. |

| Failed lights | Check the load resistor to ensure it is not faulty. You can test the resistor using a multimeter to verify its functionality. Additionally, inspect the wiring connections and make sure they are secure and not damaged. |

By following these troubleshooting tips, you can address common issues that may arise during load resistor installation. Remember to always prioritize safety and consult the instructions provided by the manufacturer for specific installation guidance.

Maintaining Load Resistors For Long-Term Performance

Maintaining Load Resistors for Long-Term Performance

Load resistors play a crucial role in ensuring the proper functioning of LED lights. However, to keep them in optimal condition and maintain their longevity, it is essential to follow best practices, regularly inspect and maintain them, and know when to replace them. By doing so, you can ensure that your LED lights continue to deliver their maximum performance. In this section, we will discuss the best practices for ensuring the longevity of load resistors, the importance of regular maintenance and inspection, and when it is time to replace load resistors.

Best practices for ensuring the longevity of load resistors

When it comes to load resistors, following some best practices can significantly contribute to their long-term performance. Here are a few things to keep in mind:

- Proper installation: Ensure that the load resistors are correctly installed, following the manufacturer’s guidelines and recommendations. This includes proper wiring, grounding, and protection against any external elements that could cause damage or interfere with their functionality.

- Appropriate sizing: Use load resistors with the correct capacity for your LED lights. Using undersized resistors can lead to overheating and premature failure, while oversized resistors may not provide the desired load balancing effect.

- Quality components: Invest in high-quality load resistors from reputable manufacturers. Quality components are more likely to withstand the test of time and provide consistent performance.

- Temperature management: Make sure that the load resistors have appropriate heat dissipation mechanisms in place, such as heat sinks or fans. Proper temperature management prevents overheating, which can damage the resistors and reduce their lifespan.

Regular maintenance and inspection of load resistors

Regular maintenance and inspection of load resistors are vital to identify any potential issues before they escalate. Here are some maintenance practices you can follow:

- Visual inspection: Regularly inspect the load resistors for any visible signs of damage, such as burned or melted components, loose connections, or signs of corrosion.

- Testing: Use a multimeter or other appropriate testing devices to measure the resistance and ensure that the load resistors are operating within the specified range.

- Cleaning: Clean the load resistors periodically to remove any dust, dirt, or other contaminants that may accumulate on the surface. This helps maintain the proper functioning of the resistors and prevents potential issues caused by obstructions or poor contact.

When to replace load resistors

Load resistors, like any other electronic component, have a limited lifespan. Despite following maintenance practices, there will come a time when they need to be replaced. Here are a few indications that it may be time for a replacement:

- Inconsistent performance: If you notice a decrease in the performance of your LED lights, such as flickering or dimming, it could indicate a failing load resistor.

- Overheating: Excessive heat emitted from the load resistors or the surrounding area is a clear sign of potential failure.

- Visible damage: Physical damage, such as burnt or melted components, should raise concerns and prompt a replacement.

- Resistance outside the specified range: If the resistance of the load resistors deviates significantly from the manufacturer’s specifications, it may be time for a replacement.

By adhering to these best practices, performing regular maintenance and inspection, and knowing when to replace load resistors, you can ensure optimal performance and longevity for your LED lights. Take the necessary steps to maintain your load resistors, and you will enjoy consistent and reliable illumination for years to come.

Frequently Asked Questions Of How To Install Load Resistors For Led Lights

Do I Need A Load Resistor For Led Lights?

Yes, you need a load resistor for LED lights. LED lights have lower wattage compared to traditional bulbs, so a load resistor is necessary to avoid hyperflashing or flickering issues. It helps balance the current and prevents damage to the LED lights.

Where Does A Led Load Resistor Go?

A LED load resistor should be installed in parallel with the LED bulb to prevent hyperflashing or other electrical issues.

Can You Use Load Resistors For Led Headlights?

Yes, you can use load resistors for LED headlights. Load resistors help prevent error messages or flickering caused by the lower power draw of LED lights compared to traditional bulbs. They simulate the load of a regular bulb, allowing LED headlights to function properly.

How Big Of A Resistor Do I Need For An Led?

To determine the size of resistor needed for an LED, you’ll need to calculate the resistor value using Ohm’s Law. This formula is R = (V_source – V_LED) / I_LED, where V_source is the supply voltage, V_LED is the LED’s voltage drop, and I_LED is the desired LED current.

Conclusion

Installing load resistors for LED lights is a crucial step in ensuring their proper functionality. By reducing the electrical load and preventing hyperflashing or bulb-out warnings, these resistors help achieve a seamless LED lighting experience. Remember to follow the manufacturer’s instructions, utilize the necessary tools, and prioritize safety throughout the installation process.

With these guidelines in mind, you can enjoy the benefits of energy-efficient and long-lasting LED lighting in your vehicle or home.