To install brake calipers, first, position the caliper over the brake rotor, aligning the mounting holes. Then, insert the caliper bolts, tighten them securely, and attach the brake line.

Finally, bleed the brake system to remove any air bubbles. Installing brake calipers involves a few straightforward steps to ensure proper braking performance. This guide will walk you through the process, allowing you to save time and money by performing the installation yourself.

By following these steps, you’ll have your brake calipers securely and correctly installed, ensuring your vehicle’s safety on the road. So, let’s get started and learn how to install brake calipers effectively and efficiently.

Why Brake Calipers Are Essential For Safe Driving

Brake calipers are essential components of a vehicle’s braking system, playing a crucial role in ensuring safe driving. These small yet powerful devices are responsible for exerting pressure on the brake pads, causing them to clamp down on the rotors and slow down or stop the vehicle. In this article, we will explore the importance of brake calipers in the braking system, their role in ensuring vehicle safety, and provide an overview of their components and functions.

Importance of Brake Calipers in the Braking System

Brake calipers are vital to the smooth functioning of a vehicle’s braking system. Their primary purpose is to convert the hydraulic pressure exerted by the brake pedal into the physical force necessary to stop the vehicle. Without brake calipers, the brake pads would be unable to make sufficient contact with the rotors, resulting in ineffective braking performance.

Moreover, brake calipers help distribute the braking force evenly across all the wheels of the vehicle. This ensures that each wheel slows down or stops at the same rate, preventing skidding or loss of control. Whether you’re driving on a busy highway or navigating through winding roads, reliable brake calipers are crucial for maintaining control and safely stopping your vehicle.

Role of Brake Calipers in Ensuring Vehicle Safety

Vehicle safety is of utmost importance, and brake calipers play a significant role in achieving this. By applying pressure to the brake pads, calipers create friction against the rotors, converting the kinetic energy of the moving vehicle into heat energy. This process allows the vehicle to slow down or come to a complete stop.

Without properly functioning brake calipers, the braking system may experience issues such as poor brake response, uneven braking, or reduced stopping power. These problems can lead to longer braking distances, increased risk of accidents, and compromised safety for both the driver and passengers. Therefore, ensuring that your brake calipers are well-maintained and in good working condition is vital for safe driving.

Overview of Brake Caliper Components and Functions

To fully understand the importance and role of brake calipers, it’s essential to familiarize yourself with their key components and functions. The main components of a brake caliper include:

| Component | Function |

|---|---|

| Piston | Applies pressure to the brake pads |

| Brake Pads | Creates friction against the rotors |

| Caliper Housing | Holds the brake components securely in place |

| Slide Pins | Allow the caliper to move and adjust according to the brake pad wear |

Working in unison, these components ensure smooth and effective braking performance. Regular inspection and maintenance of brake calipers, including cleaning and lubrication of the slide pins, are essential to ensure their optimal functioning.

- Inspect brake calipers for any signs of damage or wear.

- Clean caliper components carefully using a suitable brake cleaner.

- Apply a thin layer of lubricant to the slide pins to facilitate smooth movement.

By understanding the significance of brake calipers in the braking system, their role in ensuring vehicle safety, and the components involved, you can better appreciate the importance of regular maintenance and address any issues promptly. Remember, properly functioning brake calipers are key to a safe and reliable driving experience.

Types Of Brake Calipers And Their Features

Different types of brake calipers available in the market

Brake calipers are an essential component of the braking system in your vehicle. They play a crucial role in stopping the vehicle by applying pressure to the brake pads, which then press against the rotors. There are different types of brake calipers available in the market, each with its own features and benefits. In this section, we will explore the two main types of brake calipers – floating calipers and fixed calipers, and delve into their unique characteristics.

Floating calipers vs. fixed calipers

Floating calipers, also known as sliding calipers, are the most commonly used type of brake calipers in vehicles today. As the name suggests, floating calipers have the ability to move or slide during the braking process. They are designed with one or two pistons on the inboard side of the caliper, which push the brake pads against the rotor when the brakes are applied. These calipers are typically lighter, simpler in design, and less expensive compared to fixed calipers.

In contrast, fixed calipers are a more sophisticated and robust type of caliper. They feature multiple pistons on both the inboard and outboard sides of the caliper, providing equal pressure distribution and improved braking performance. Unlike floating calipers, fixed calipers do not move or slide during operation. Instead, they remain stationary and squeeze the brake pads against the rotor from both sides. This design enhances braking efficiency, reduces brake fade, and promotes better overall braking stability.

Features and benefits of each type of brake caliper

| Floating Calipers | Fixed Calipers | |

|---|---|---|

| Construction | Single or double-piston design on the inboard side | Multiple pistons on both inboard and outboard sides |

| Braking Efficiency | Good | Excellent |

| Cost | Less expensive | More expensive |

| Weight | Lighter | Heavier |

| Brake Fade | Possible under extreme conditions | Less likely due to improved cooling |

| Braking Stability | Good | Excellent |

In summary, floating calipers are a cost-effective option with good braking efficiency, while fixed calipers offer exceptional braking performance and stability at a higher price point. The choice between the two types depends on your specific driving needs, budget, and desired braking experience. It’s important to consult with a professional mechanic or refer to your vehicle’s manual before making a decision on which type of brake caliper to install.

Tools And Materials Needed For Brake Caliper Installation

Installing brake calipers is an essential part of maintaining and repairing your vehicle’s braking system. To successfully install brake calipers, you will need specific tools, materials, and safety equipment. In this section, we will cover the essential tools required for brake caliper installation, the specific materials needed for the installation process, and the recommended safety equipment for working with brake calipers.

Essential tools required for brake caliper installation

When it comes to installing brake calipers, having the right tools is crucial. Here are the essential tools you will need:

- Socket set: A socket set with the appropriate sizes will be necessary to remove and install the caliper bolts.

- Wrenches: You will need both open-end and box-end wrenches to loosen and tighten various brake components.

- Brake bleeder kit: A brake bleeder kit is essential for removing air bubbles from the brake lines after caliper installation.

- C-clamp: A C-clamp is necessary for compressing the caliper piston back into its housing.

- Wire brush: A wire brush will come in handy to clean the caliper and brake components before installation.

- Torque wrench: A torque wrench will ensure proper tightening of the caliper bolts to the recommended specifications.

Specific materials needed for the installation process

In addition to the tools mentioned above, you will also require specific materials during the brake caliper installation. These materials include:

- New brake calipers: Depending on the condition of your existing calipers, you may need to purchase new ones for replacement.

- Brake pads: It is recommended to install new brake pads along with the calipers to ensure optimal braking performance.

- Brake fluid: Brake fluid is necessary for bleeding the brakes and ensuring proper hydraulic pressure.

- Anti-seize compound: To prevent corrosion and ensure easy removal in the future, applying anti-seize compound on the caliper bolts is highly recommended.

Recommended safety equipment for working with brake calipers

When working with brake calipers, safety should always be a top priority. Here are some recommended safety equipment you should have:

- Gloves: Wear gloves to protect your hands from brake dust, grease, and potential injuries.

- Safety goggles: Safety goggles will protect your eyes from debris and any potential brake fluid splashes.

- Jack stands: Use jack stands to securely support your vehicle while working on the brake calipers.

By having the essential tools, specific materials, and recommended safety equipment, you will be well-prepared to tackle the brake caliper installation process with confidence and ensure the safety of yourself and your vehicle.

Step-By-Step Guide On How To Install Brake Calipers

Welcome to our comprehensive step-by-step guide on how to install brake calipers. Whether you’re a seasoned DIY enthusiast or a beginner, we’ve got you covered.

Preparing the vehicle for brake caliper installation

The first step in installing new brake calipers is to prepare your vehicle. Start by parking on a flat surface and engaging the parking brake. Next, safely raise your vehicle using a jack and secure it with jack stands. Ensure the wheels are fully removed to provide easy access to the brake calipers.

Removing the old brake calipers

To remove the old brake calipers, begin by loosening the brake line fitting using a wrench. Be prepared for some brake fluid leakage, so keep a container handy. Once the fitting is loosened, remove the bolts that secure the caliper to the caliper bracket. Carefully slide the old caliper off the brake rotor and set it aside.

Cleaning and lubricating the brake caliper mounting points

Before installing the new brake calipers, it’s important to clean and lubricate the brake caliper mounting points. Use a wire brush or a suitable cleaning solvent to remove any debris or rust from the mounting surface. Apply a thin layer of high-temperature brake grease to the mounting points to ensure smooth movement and prevent corrosion.

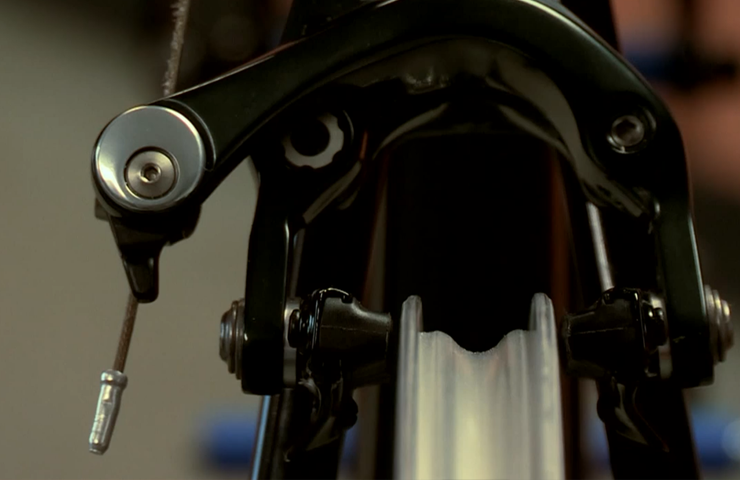

Installing the new brake calipers

Now, it’s time to install the new brake calipers. Start by carefully sliding the new caliper onto the brake rotor, aligning the bolt holes with the caliper bracket. Insert and tighten the caliper bolts, ensuring they are torqued to the manufacturer’s specifications. Double-check the caliper’s position to ensure proper alignment with the brake rotor.

Proper torque specifications for brake caliper bolts

It is crucial to tighten the brake caliper bolts to the correct torque specifications to ensure proper functioning and safety. Always refer to the vehicle’s service manual or the caliper manufacturer’s instructions for the recommended torque settings. Never over-tighten or under-tighten the caliper bolts, as this could lead to brake performance issues or damage.

Bleeding the brake system after installation

After installing the new brake calipers, it’s essential to bleed the brake system to remove any air bubbles and ensure optimal brake performance. Start by locating the brake bleeder valve on each caliper. Attach a clear plastic hose to the bleeder valve and submerge the other end in a container filled with brake fluid. Open the valve and have a helper slowly press the brake pedal while you monitor the fluid flow. Repeat this process until you see no more air bubbles in the brake fluid.

By following this step-by-step guide, you’ll be able to install new brake calipers efficiently and effectively. Remember to prioritize safety and accuracy throughout the process, and don’t hesitate to seek professional help if you’re unsure about any step. Enjoy the improved braking performance of your vehicle!

Troubleshooting Common Brake Caliper Installation Issues

Identifying potential problems during brake caliper installation

During the brake caliper installation process, there are a few potential problems that can arise. Identifying these problems early on is crucial for ensuring the proper functioning of your brake system. Here are some common issues to watch out for: 1. Caliper misalignment: One of the most common problems is the misalignment of the brake caliper. This misalignment can occur due to improper positioning or tightening of the caliper bolts. If the caliper is not properly aligned, it can result in uneven brake pad wear and reduced braking performance. 2. Caliper sticking: Another issue that may arise is caliper sticking. This occurs when the caliper fails to retract properly after applying the brakes, causing the brake pads to remain in constant contact with the rotor. Sticking calipers can lead to excessive heat, premature brake wear, and diminished performance. 3. Brake fluid leaks: Brake fluid leaks are another common problem during brake caliper installation. Leaks can occur at the caliper fittings, brake lines, or even within the caliper itself. These leaks not only pose a safety hazard but can also result in a loss of braking performance.

Solutions for brake caliper misalignment or sticking

If you encounter brake caliper misalignment or sticking during installation, here are some steps you can take to resolve the issue: 1. Reposition the caliper: Start by loosening the caliper bolts and repositioning the caliper to ensure proper alignment with the brake rotor. It’s important to double-check the alignment by visually inspecting the caliper in relation to the rotor. 2. Tighten the caliper bolts: Once the caliper is properly aligned, tighten the caliper bolts to the manufacturer’s recommended torque specifications. Be sure to use a torque wrench to achieve the correct tightness and avoid over or under-tightening. 3. Inspect brake pads and rotors: While you have the caliper off, inspect the brake pads and rotors for any signs of wear or damage. If necessary, replace worn brake pads or damaged rotors to ensure optimal braking performance.

Dealing with brake fluid leaks or air bubbles in the brake system

If you notice brake fluid leaks or air bubbles in the brake system during caliper installation, immediate action is required. Here are the steps to address these issues: 1. Inspect brake lines and fittings: Carefully inspect all brake lines and fittings for signs of leaks or loose connections. Tighten any loose fittings and replace any damaged brake lines. 2. Bleed the brake system: If air bubbles are present in the brake system, you will need to bleed the system to remove the trapped air. Follow the manufacturer’s instructions to perform a proper brake bleeding procedure. Starting from the furthest brake caliper, work your way towards the master cylinder, ensuring all air is expelled from the system. 3. Check brake fluid level: Ensure the brake fluid level is at the recommended level in the master cylinder reservoir. If necessary, add the appropriate brake fluid to bring it to the correct level. By following these troubleshooting steps, you can tackle common brake caliper installation issues and ensure the reliable and safe functioning of your brake system. Don’t hesitate to consult a professional mechanic or refer to your vehicle’s service manual for further guidance if needed.

Professional Tips For Brake Caliper Installation

Expert advice on best practices for brake caliper installation

Installing brake calipers properly is crucial for maintaining optimal braking performance and ensuring your safety on the road. With the right tools and techniques, you can complete this task like a pro. Here are some expert tips to help you achieve a successful and smooth brake caliper installation:

- Gather the necessary tools and materials: Before you begin, make sure you have all the required tools and materials at hand. This typically includes a socket wrench, a torque wrench, brake cleaner, brake lubricant, and a brake caliper rebuild kit if needed. Having everything ready before you start will save you time and ensure you have everything you need to complete the installation.

- Remove the old caliper with caution: Start by safely raising and supporting your vehicle, and removing the wheel to access the caliper. Take note of the position of the caliper and its mounting hardware before removing it, as this will make the reinstallation process easier. Inspect the caliper for any signs of damage or wear, and replace it if necessary.

- Clean and lubricate the caliper components: Thoroughly clean the caliper brackets, slide pins, and mounting surfaces with brake cleaner to remove any dirt, debris, or old lubricant. Once cleaned, apply a thin layer of brake lubricant to the slide pins and any areas of metal-to-metal contact. This will ensure smooth and proper caliper movement.

- Take care when torquing the caliper bolts: When attaching the caliper to the brackets, be sure to use a torque wrench and follow the manufacturer’s recommended torque specifications. Over-tightening can lead to caliper damage, while under-tightening may cause the caliper to loosen during operation, resulting in poor braking performance.

- Inspect and replace brake hardware: While the caliper is off, take the opportunity to inspect the brake hardware, such as the pad clips, shims, and springs. Replace any worn or damaged hardware to ensure proper brake pad alignment and function.

Common mistakes to avoid during the installation process

When installing brake calipers, it’s important to be aware of common mistakes that can compromise the effectiveness of your braking system. By avoiding these pitfalls, you can ensure a successful installation. Here are some common mistakes to watch out for:

- Improper cleaning: Failing to clean the caliper brackets and other components thoroughly can result in poor caliper movement and uneven brake pad wear. Take the time to remove any built-up dirt or debris before reassembling the caliper.

- Incorrect caliper alignment: Inserting the brake pads into the caliper without proper alignment can lead to uneven pad wear and reduced braking performance. Take care to align the pads correctly with the rotor, ensuring an even contact surface.

- Forgetting to bleed the brake system: If you have disconnected the brake lines during the caliper installation process, it is essential to bleed the brake system afterward. This will remove any air bubbles and ensure proper brake fluid flow and pressure.

- Neglecting to replace worn brake hardware: Reusing worn or damaged brake hardware can compromise brake pad alignment and performance. Always inspect and replace any worn or damaged hardware for optimal brake caliper function.

Additional tips for ensuring optimal brake caliper performance

To maximize the performance and longevity of your brake calipers, consider the following additional tips:

- Regular maintenance: Perform regular maintenance on your brake system, including checking for leaks, inspecting brake pads, and cleaning caliper components. This will help catch any potential issues early and prolong the life of your calipers.

- Use quality brake parts: When replacing brake calipers or other brake components, opt for high-quality parts from reputable manufacturers. This will ensure proper fitment, durability, and reliable performance.

- Follow manufacturer’s guidelines: Always consult the vehicle manufacturer’s instructions and guidelines when performing brake caliper installation. This will ensure you follow the correct procedures and specifications for your specific vehicle make and model.

- Seek professional assistance if needed: If you’re unsure about any aspect of installing brake calipers or encounter any issues during the process, it’s best to seek professional assistance from a qualified mechanic. They have the expertise and tools necessary to ensure a safe and proper installation.

By following these professional tips, avoiding common mistakes, and taking additional precautions, you can confidently install brake calipers and maintain a reliable braking system that keeps you safe on the road.

Importance Of Regular Maintenance And Inspection For Brake Calipers

Proper maintenance and regular inspections of brake calipers are essential for safe and efficient braking performance. Brake calipers play a crucial role in the braking system of your vehicle, as they house the brake pads and facilitate the movement of the brake pistons. Over time, brake calipers can become worn-out, leading to decreased braking efficiency, potential brake failure, and increased risk of accidents. By adhering to a routine maintenance schedule and performing regular inspections, you can identify and address any issues with your brake calipers before they become major problems.

The significance of routine brake caliper maintenance

Routine brake caliper maintenance is critical for ensuring optimal performance and safety on the road. Neglecting this important aspect of your vehicle’s braking system can have serious consequences, including:

- Reduced braking power: Worn or damaged brake calipers can lead to decreased brake pad contact with the rotor, resulting in reduced braking power. This can significantly increase stopping distances, putting you and other drivers at risk.

- Uneven brake pad wear: Over time, faulty brake calipers can cause uneven wear on the brake pads. This can lead to costly repairs and replacements if not addressed promptly.

- Brake fluid leaks: Damaged brake calipers can develop leaks, leading to a loss of brake fluid. Low brake fluid levels can impair the entire braking system, compromising your ability to stop safely.

- Increased risk of accidents: Faulty brake calipers can result in unpredictable and unreliable braking, making it more difficult to respond to sudden obstacles or emergencies on the road.

By conducting routine brake caliper maintenance, you can prevent these issues from arising and ensure that your braking system is operating at its best.

How to inspect brake calipers for signs of wear or damage

Regular inspections of your brake calipers can help you identify any signs of wear or damage before they become major issues. Here’s a step-by-step guide on how to inspect your brake calipers:

- Start by visually examining the brake caliper for any obvious signs of damage, such as cracks, leaks, or excessive rust.

- Check for any abnormal brake pad wear patterns, such as uneven wear on one side or excessive wear on the inner or outer edges.

- Verify that the brake caliper slides and moves freely. If it feels stuck or difficult to move, it may require lubrication or replacement.

- Inspect the brake caliper pistons for any signs of leaking brake fluid or corrosion. These issues can affect the caliper’s ability to apply even pressure to the brake pads.

- Ensure that the brake caliper bolts are secure and properly tightened. Loose bolts can lead to caliper misalignment and uneven brake pad wear.

By performing these simple inspections regularly, you can catch potential brake caliper issues early on and take the necessary steps to address them.

When to seek professional assistance for brake caliper issues

While regular maintenance and inspections are crucial, certain brake caliper issues may require professional assistance. It’s important to be aware of the signs that indicate you should seek the help of a qualified mechanic. Consider contacting a professional if you notice any of the following:

- Unusual noises, such as grinding or squealing, coming from the brakes

- The brake pedal feels spongy or requires excessive pressure to engage

- The vehicle pulls to one side when braking

- Visible brake fluid leaks or a low brake fluid level

- Any other noticeable changes in braking performance or behavior

A trusted mechanic will have the expertise to diagnose and fix any complex brake caliper issues, ensuring the safety and reliability of your vehicle’s braking system.

Frequently Asked Questions For How To Install Brake Calipers

Can You Install Brake Calipers Yourself?

Yes, you can install brake calipers yourself. It’s a relatively straightforward process that can save you money. Just make sure to follow the manufacturer’s instructions and use the correct tools. If you’re unsure or uncomfortable, it’s best to consult a professional.

How Do You Install A Brake Caliper On A Car?

To install a brake caliper on a car, follow these steps: 1. Lift the car and remove the wheel. 2. Unbolt the old caliper and detach it from the brake rotor. 3. Install the new caliper and secure it with bolts.

4. Reattach the brake line and bleed the system. 5. Put the wheel back on and lower the car.

How Long Does It Take To Install Brake Calipers?

Brake caliper installation usually takes around 1-2 hours, depending on the complexity of the vehicle. The process involves removing the old calipers, installing new ones, and bleeding the brake system to ensure proper functionality.

How Do You Determine Brake Caliper Mounting Positions?

To determine brake caliper mounting positions, follow these steps: 1. Identify the brake caliper’s correct placement on the brake rotor. 2. Position the caliper so that it aligns with the brake pad and rotor properly. 3. Ensure that the mounting brackets and bolts are securely attached.

4. Double-check that the caliper is centered and level with the rotor. 5. Test the brake system to verify the correct mounting position and proper functionality.

Conclusion

Installing brake calipers can be a complex task, but with the right tools and guidance, it becomes achievable for any car enthusiast. By following the step-by-step instructions and safety precautions outlined in this blog post, you can ensure a successful brake caliper installation.

Remember to double-check all connections and test the brakes before hitting the road. With proper care and maintenance, you can enjoy smooth and safe braking for miles to come. So, roll up your sleeves and get ready to give your vehicle the stopping power it deserves!