To install an air suspension dump valve, first, locate the air suspension system and identify the dump valve’s mounting location. Then, connect the valve to the air suspension system and secure it in place using appropriate fittings and fasteners.

Air Suspension Dump Valve: A Quick Overview

Installing an air suspension dump valve is a great way to enhance the performance and functionality of your vehicle’s air suspension system. In this section, we will provide a quick overview of what an air suspension dump valve is and the benefits it offers. So let’s jump right in and explore more about this essential component!

What is an air suspension dump valve?

An air suspension dump valve, also known as an exhaust valve or an air release valve, is an essential component of an air suspension system. It is responsible for releasing excess air pressure from the system, thus allowing the vehicle to sit lower to the ground. The dump valve comes into action when you want to quickly deflate the airbags and lower the vehicle’s ride height. This can be handy in various situations, such as off-roading or loading and unloading heavy cargo.

Benefits of installing an air suspension dump valve

Installing an air suspension dump valve offers several benefits for your vehicle and driving experience. Let’s take a look at some of the key advantages:

- Improved ride comfort: By adjusting the ride height of your vehicle, an air suspension dump valve allows you to fine-tune the comfort of your ride. You can lower your vehicle for a smoother and more stable ride, especially on rough terrains or when carrying heavy loads.

- Enhanced handling and control: With an air suspension dump valve, you can quickly adjust the ride height to adapt to different driving conditions. This helps to improve handling and control, especially during cornering or when driving on uneven surfaces.

- Extended air suspension system lifespan: By releasing excess air pressure from the system, an air suspension dump valve helps to relieve strain on the components, thus potentially extending their lifespan. This can result in fewer repairs and maintenance costs down the line.

- Convenient and versatile: The ability to lower the ride height of your vehicle with a dump valve offers added convenience in various situations. Whether you need to load or unload cargo, access low clearance areas, or personalize your vehicle’s appearance, an air suspension dump valve gives you the flexibility to adapt to your needs.

Overall, installing an air suspension dump valve can greatly enhance your driving experience by providing improved ride comfort, enhanced handling and control, and added versatility. It is a worthwhile investment that offers both practical and aesthetic benefits for your vehicle.

Tools And Materials Needed For Installation

Installing an air suspension dump valve can greatly enhance the performance and functionality of your vehicle’s suspension system. Whether you are looking to improve the towing capabilities of your truck or want to achieve that perfect stance on your custom car, having the right tools and materials is crucial for a successful installation. In this section, we will outline the list of tools required for the installation process and recommend materials that will ensure a seamless and efficient installation.

List of tools required for the installation process

Before you begin the installation, it is essential to have the following tools readily available:

- Socket wrench set

- Adjustable wrench

- Allen wrench set

- Wire strippers

- Electrical tape

- Multimeter

- Drill

- Wire crimping tool

- Heat shrink tubing

- Flathead and Phillips screwdrivers

Having these tools at your disposal will enable you to tackle any challenges that may arise during the installation process. From removing existing components to securing the new dump valve in place, each tool serves a specific purpose and will ensure a smooth installation experience.

Recommended materials for a successful installation

In addition to the tools mentioned above, it is essential to have the following materials to ensure a successful installation:

- Thread sealant

- Airline tubing

- Compression fittings

- Electrical connectors

- Mounting brackets

- Wiring harness

Using thread sealant will prevent any air leaks, ensuring optimal performance of your air suspension system. Airline tubing and compression fittings are vital for securely connecting the dump valve to the air suspension components. Additionally, utilizing quality electrical connectors and a wiring harness will give you peace of mind knowing that your system is securely and reliably connected. Lastly, mounting brackets are necessary to properly secure the dump valve in the desired location.

Paying attention to the choice and quality of your materials will not only guarantee a successful installation but also ensure the longevity and reliability of your air suspension dump valve.

Step-By-Step Guide: How To Install Air Suspension Dump Valve

If you’re looking to improve your vehicle’s air suspension system, installing an air suspension dump valve is a great way to gain better control and performance. In this step-by-step guide, we will walk you through the process of installing an air suspension dump valve to ensure a successful and hassle-free installation. Let’s get started!

Preparing the vehicle for installation

The first step in installing an air suspension dump valve is to prepare your vehicle. Here are the essential tasks you need to perform before you begin the installation:

- Ensure the vehicle is parked on a level surface and the engine is turned off.

- Locate the air suspension system and familiarize yourself with the layout and components.

- Gather all the necessary tools and equipment, such as a wrench set, pliers, and electrical tape.

- Refer to the vehicle’s manual or consult an expert to understand any specific requirements or precautions for your particular vehicle model.

Identifying the location for the dump valve

Before you can install the new air suspension dump valve, you need to identify the ideal location for its placement. Here’s how you can do it:

- Inspect the air suspension system carefully to find a suitable spot with enough space and accessibility for the dump valve.

- Consider factors such as proximity to airbags or air lines, ease of connection, and protection from road debris or weather conditions.

- Ensure there is enough clearance to install the dump valve without interfering with other components.

Removing the old valve

Once you’ve identified the location for the dump valve, the next step is to remove the old valve. Follow these steps to complete the removal process:

- Use a wrench or pliers to disconnect the electrical connections and air lines connected to the old dump valve.

- Securely hold the valve in place to avoid any accidental damage or injury during removal.

- Unscrew any mounting bolts or screws securing the old dump valve to the vehicle.

- Gently remove the old dump valve, taking care not to damage any surrounding components.

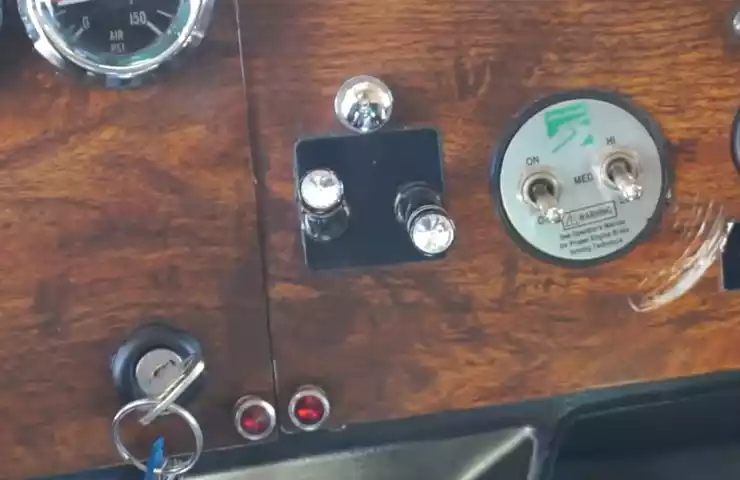

Installing the new air suspension dump valve

Now that you’ve removed the old valve, it’s time to install the new air suspension dump valve. Follow these steps for a successful installation:

- Begin by positioning the new dump valve in the previously identified location, ensuring a secure fit.

- Tighten the mounting bolts or screws to secure the new valve in place.

- Connect the electrical connections and air lines to the corresponding ports on the new dump valve.

- Double-check all connections and ensure they are tight and secure.

Connecting the valve to the air suspension system

With the new dump valve installed, it’s time to connect it to the air suspension system. Here’s how you can do it:

- Identify the air supply line in the air suspension system, usually located near the compressor.

- Using a suitable connector or adapter, connect the air supply line to the inlet port of the dump valve.

Testing the valve for proper functionality

Before you conclude the installation process, it’s essential to test the new dump valve for proper functionality. To do this, follow these steps:

- Turn the engine on and allow the air suspension system to charge fully.

- Activate the dump valve by either using a manual switch or the vehicle’s control panel.

- Observe the air suspension system and listen for any abnormalities or leaks.

- Verify that the dump valve effectively releases the excess air, lowering the vehicle’s suspension appropriately.

By following this step-by-step guide, you can successfully install an air suspension dump valve and enjoy the benefits it brings to your vehicle’s air suspension system. Ensure to always consult the vehicle’s manual or seek professional advice if you encounter any challenges during the installation.

Troubleshooting Common Issues During Installation

Installing an air suspension dump valve can significantly enhance the performance and adjustability of your vehicle’s suspension system. However, like any installation process, it’s not uncommon to encounter some challenges along the way. This section will highlight the problems you may face during the installation process, provide solutions to common installation challenges, and offer tips to ensure a smooth and hassle-free installation experience.

Problems you may encounter during the installation process

When installing an air suspension dump valve, there are a few common issues that you may come across. By being aware of these problems, you can plan ahead and prevent any potential headaches during the installation. Here are some problems you should watch out for:

- Leaking fittings or connections: A common issue when installing an air suspension dump valve is encountering leaking fittings or connections. This can result in air loss, reducing the efficiency of the suspension system.

- Incompatible components: Using incompatible components can lead to difficulties during the installation process. It’s crucial to ensure that all the parts you’re using are compatible with your specific vehicle make and model.

- Incorrect wiring: Improperly wiring the air suspension dump valve can cause it to function improperly or not work at all. It’s important to carefully follow the manufacturer’s instructions and double-check your wiring connections.

- Insufficient clearance: In some cases, you may encounter clearance issues when installing the air suspension dump valve. This can be due to the location of other components or lack of available space. It’s vital to choose an installation location that provides enough clearance for the valve to function properly.

Solutions to common installation challenges

While encountering challenges during the installation process is frustrating, there are solutions that can help you overcome these common issues. Here are some solutions to the challenges mentioned earlier:

| Installation Challenge | Solution |

|---|---|

| Leaking fittings or connections | Thoroughly check all fittings and connections for leaks. Tighten any loose fittings and replace any damaged parts. Consider using thread sealant or Teflon tape on fittings to ensure a tight and leak-free seal. |

| Incompatible components | Before purchasing any components, thoroughly research and ensure compatibility with your vehicle’s make and model. Consult with experts or the manufacturer if needed to confirm compatibility. |

| Incorrect wiring | Refer to the manufacturer’s instructions and wiring diagram carefully. Double-check all wiring connections to ensure they are properly connected according to the provided guidelines. Seek professional assistance if needed to ensure correct wiring. |

| Insufficient clearance | Choose an installation location that provides adequate clearance for the air suspension dump valve. Consider relocating other components if necessary to create enough space for the valve to function without any obstructions. |

Tips to ensure a smooth installation experience

Follow these tips to ensure a smooth and trouble-free installation of your air suspension dump valve:

- Read the installation instructions thoroughly: Before starting the installation process, carefully read and understand the manufacturer’s installation instructions. Familiarize yourself with the components and steps involved.

- Gather all necessary tools and materials: Ensure you have all the necessary tools and materials before beginning the installation. This includes any additional wiring, adapters, or fittings that may be required.

- Double-check compatibility: Before purchasing any components, double-check their compatibility with your specific vehicle make and model. This will help prevent any compatibility issues during the installation.

- Take your time: Rushing through the installation process can lead to mistakes. Take your time and give each step the attention it deserves. This will minimize the chances of errors and save you time in the long run.

- Seek professional assistance if needed: If you’re unsure about any aspect of the installation process, don’t hesitate to seek professional assistance. Consulting with an expert can ensure a proper and safe installation.

By being aware of the problems that may arise, knowing the solutions to common installation challenges, and following these helpful tips, you can have a successful and stress-free installation experience for your air suspension dump valve.

Maintenance And Upkeep Of Air Suspension Dump Valve

Proper maintenance and upkeep of your air suspension dump valve are essential to ensure optimal performance and longevity. Regular cleaning, lubrication, and inspection can help identify and address any potential issues before they become major problems. Additionally, knowing when to replace a worn-out or malfunctioning valve is crucial for maintaining the overall functionality of your air suspension system. In this section, we will delve into the key aspects of maintenance and upkeep for your air suspension dump valve.

Cleaning and lubricating the valve for optimal performance

To maintain the optimal performance of your air suspension dump valve, regular cleaning and lubrication are necessary. Keep in mind that dirt, dust, and debris can accumulate over time, leading to reduced functionality. Here are the steps to clean and lubricate your valve:

- Start by disconnecting the valve from the air suspension system, following the manufacturer’s instructions.

- Using a mild cleaning solution and a soft cloth, gently wipe the exterior of the valve to remove any dirt or grime.

- Inspect the valve for signs of damage or wear, such as cracks or leaks. If any issues are detected, consider replacing the valve.

- Apply a small amount of silicone-based lubricant to the moving parts of the valve. This helps reduce friction and ensures smooth operation.

- Reattach the valve to the air suspension system, ensuring all connections are secure.

Regular inspection to identify any potential issues

Performing regular inspections on your air suspension dump valve is vital for identifying any potential issues and addressing them promptly. Here are some key inspection points to consider:

- Visually examine the valve for any visible cracks, leaks, or signs of wear.

- Check the valve’s mounting brackets and connections to ensure they are secure.

- Inspect the valve’s electrical wiring for any fraying or damage.

- Monitor the valve’s performance during operation, listening for any unusual noises or delays in pressure release.

Replacement guidelines for worn-out or malfunctioning valves

Eventually, your air suspension dump valve may reach a point where it needs to be replaced. Here are some guidelines to help you determine when it’s time for valve replacement:

- If you notice persistent leaks or cracks on the valve, it is an indication of significant wear and tear.

- When the valve fails to release the air pressure effectively or causes delays in the leveling process, it may be malfunctioning.

- In case of electrical failure where the valve is unresponsive or behaves erratically, a replacement is typically necessary.

- Consult the manufacturer’s guidelines to determine the average lifespan of the valve and consider replacement after reaching that milestone.

Remember, a properly maintained and functioning air suspension dump valve is crucial for the overall performance and safety of your vehicle. By following these maintenance and upkeep guidelines, you can ensure that your air suspension system operates smoothly and efficiently for a long time.

Frequently Asked Questions

Here are the answers to some commonly asked questions about installing an air suspension dump valve:

Can I install an air suspension dump valve myself?

Yes, it is possible to install an air suspension dump valve yourself, especially if you have some basic knowledge of your vehicle’s suspension system and are comfortable working with tools. However, if you are unsure of your abilities or have never worked on your vehicle before, it is always advisable to consult a professional mechanic. They have the experience and expertise to ensure the installation is done correctly and safely.

How long does it take to install an air suspension dump valve?

The time it takes to install an air suspension dump valve can vary depending on a few factors. The complexity of your vehicle’s suspension system, your level of experience, and the availability of tools can all play a role in the installation time. On average, it may take a few hours to complete the installation. This includes removing the necessary parts, installing the dump valve, and reassembling everything. However, it’s important to take your time and follow the manufacturer’s instructions to ensure the job is done right.

What are the safety precautions I should follow during installation?

Installing an air suspension dump valve requires careful attention to safety. Here are some important precautions to keep in mind:

- Always work in a well-ventilated area to avoid inhaling any fumes or gases.

- Ensure the vehicle is parked on a flat and stable surface, with the parking brake engaged.

- Use the appropriate safety gear, such as gloves and eye protection, to protect yourself from any potential injuries.

- Before starting the installation, be sure to disconnect the vehicle’s battery to avoid any electrical mishaps.

- Follow the manufacturer’s instructions carefully and double-check all connections and fittings before testing the system.

- If you are unsure about any step of the installation process, it’s always best to consult a professional mechanic.

By following these safety precautions, you can ensure that the installation of your air suspension dump valve is done safely and effectively.

Frequently Asked Questions For How To Install Air Suspension Dump Valve

How Do You Install A Rapid Dump Valve?

To install a rapid dump valve, follow these steps: 1. Locate the appropriate spot on your vehicle’s air tank. 2. Ensure the vehicle’s air system is depressurized. 3. Remove the existing valve and replace it with the rapid dump valve. 4.

Securely tighten the valve using the provided fittings. 5. Test the valve to ensure proper functionality.

How Does Air Suspension Dump Valve Work?

The air suspension dump valve works by releasing air from the suspension system to lower the vehicle’s ride height. When the valve is activated, it opens to allow air to escape, reducing the pressure in the air springs and lowering the car.

This helps improve stability and handling.

How Does A Dump Valve Work On A Trailer?

A dump valve on a trailer releases air pressure, allowing the trailer to lower its bed or unload cargo. This happens when the valve is activated, enabling air to escape and lowering the trailer’s suspension.

Why Is My Suspension Dump Light Flashing?

The suspension dump light may flash due to a fault in the suspension system. It is important to get it checked by a professional to diagnose and fix the issue, ensuring optimal performance and safety.

Conclusion

Installing an air suspension dump valve is a crucial step in enhancing the performance and safety of your vehicle’s air suspension system. By following the step-by-step guide in this blog post, you can ensure a seamless installation process. Remember to refer to the manufacturer’s instructions for specific details.

With the dump valve in place, you’ll have better control over your vehicle’s ride height and improved maneuverability. Enjoy the enhanced comfort and stability that air suspension provides!Categories.