To install Air Lift Air Bags, begin by locating the appropriate mounting points on your vehicle’s frame and ensuring that the air bags are properly positioned. Then, secure the air bags to the frame using the provided brackets and hardware.

What Are Air Lift Air Bags?

Air Lift air bags are a suspension upgrade that provide additional support to your vehicle’s suspension system. They are designed to help control the ride and handling of your vehicle, especially when towing or carrying heavy loads.

Definition and Function of Air Lift Air Bags

Air Lift air bags, also known as air springs, are flexible and inflatable components that fit inside the existing coil or leaf springs of your vehicle. They work by using compressed air to support the load and provide extra stability.

These air bags consist of a heavy-duty rubber bladder, which is made of durable materials that can withstand the weight and pressure exerted by your vehicle. The air bags are connected to an air compressor and a control system that allows you to adjust the air pressure according to your specific needs.

When the air bags are inflated, they increase the suspension capacity of your vehicle, resulting in improved ride quality, better load leveling, and enhanced stability. By adjusting the air pressure, you can customize the level of support provided by the air bags, ensuring optimal performance based on your load requirements.

Key Benefits of Using Air Lift Air Bags in Vehicles

Using air lift air bags in your vehicle can offer a range of benefits that enhance both the performance and safety of your ride. Here are some key advantages:

- Improved Load-Leveling: Air bags help to distribute the weight evenly across all four wheels, preventing sagging or uneven suspension when towing or carrying heavy loads. This ensures a more stable and controlled ride.

- Enhanced Ride Quality: Air Lift air bags provide additional support to your vehicle’s suspension system, resulting in a smoother and more comfortable ride – especially when driving on uneven terrains or bumpy roads.

- Adjustable Support: With the ability to adjust the air pressure, you can easily customize the level of support provided by the air bags. This allows you to adapt to different load requirements, ensuring optimal performance.

- Reduced Bottoming-Out: Air bags act as a cushion between the axle and the frame, minimizing the risk of bottoming-out when encountering bumps or obstacles on the road.

- Improved Vehicle Stability: By eliminating excessive sway and bounce, air bags enhance the overall stability of your vehicle, making it easier to control and reducing the risk of accidents or loss of control.

- Extended Tire Life: Proper load distribution and suspension support provided by air bags can help prevent premature tire wear, saving you money on frequent tire replacements.

By installing air lift air bags in your vehicle, you can enjoy a smoother, more stable ride, enhanced control, and improved safety while towing or carrying heavy loads. These reliable suspension upgrades offer a range of benefits that can significantly enhance your driving experience.

Types Of Air Lift Air Bags

When it comes to enhancing the ride quality and load-carrying capacity of your vehicle, installing air bags can be a game-changer. Air Lift offers a range of air bags that cater to different needs and preferences. In this article, we will explore the various types and models of Air Lift air bags available in the market, along with their pros and cons.

Different types and models of air lift air bags available in the market

1. Air Lift 1000 Series: The Air Lift 1000 series is designed for light-duty applications and offers load-leveling support by adjusting the air pressure according to the weight being carried. These air bags are made of durable and high-quality materials, making them suitable for everyday use. They are available for a wide range of vehicles, including sedans, SUVs, and light trucks.

2. Air Lift LoadLifter 5000: Specifically designed for heavy-duty applications, the Air Lift LoadLifter 5000 air bags are ideal for trucks, vans, and SUVs that frequently carry heavy loads. These air bags provide maximum load support and help eliminate sag, ensuring a stable and comfortable ride even when hauling considerable weight.

3. Air Lift SlamAir: If you are looking to lower your vehicle’s suspension while maintaining load support, the Air Lift SlamAir air bags are an excellent choice. These air bags are specifically crafted for lowered trucks, sports cars, and custom vehicles, allowing you to achieve the desired stance without compromising on performance and handling.

Pros and cons of each type

| Type | Pros | Cons |

|---|---|---|

| Air Lift 1000 Series | Easy installation and adjustmentEnhanced ride comfort and stabilityDurable construction for long-lasting performanceCompatibility with a wide range of vehicles | Lower weight capacity compared to heavy-duty modelsLess ideal for heavy loads and towing |

| Air Lift LoadLifter 5000 | Excellent load support for heavy-duty applicationsEliminates rear-end sag and improves stabilityEasy to install and adjustEnhanced towing and hauling capabilities | Not suitable for light-duty vehiclesMay slightly reduce ride comfort when unloaded |

| Air Lift SlamAir | Allows for lowered vehicle suspension without compromising load supportImproved handling and performance for lowered vehiclesEasy to install and adjustCompatible with custom and sports cars | Not designed for heavy loads or towingMay slightly reduce ride comfort compared to stock suspension |

In conclusion, Air Lift offers different types and models of air bags to meet specific needs and preferences. Whether you require load-leveling support, heavy-duty load carrying capabilities, or the flexibility of lowered suspension, Air Lift has a solution for you. Consider the pros and cons of each type before selecting the air bags that best suit your vehicle and intended use.

Key Components For Installation

Installing air lift air bags is a great way to improve the suspension and load-carrying capacity of your vehicle. However, to ensure a successful installation, it is important to have the right components. In this section, we will discuss the key components that are necessary for installing air lift air bags.

List of essential components required for installing air lift air bags

Before you start the installation process, make sure you have the following components:

- Air Lift air bags

- Air compressor

- Air lines

- Air fittings

- Mounting brackets

- Hardware

These components are essential for a successful installation and ensure the proper functioning of your air lift air bags.

Importance and function of each component

Let’s take a closer look at each component and understand their importance and function:

Air Lift air bags

The air bags themselves are the main component of the system. These durable and flexible bags are designed to support the weight of your vehicle when it is under load. They are made from high-quality materials and are built to withstand heavy loads and rough terrains. The air bags can be inflated or deflated to provide the desired level of support and stability.

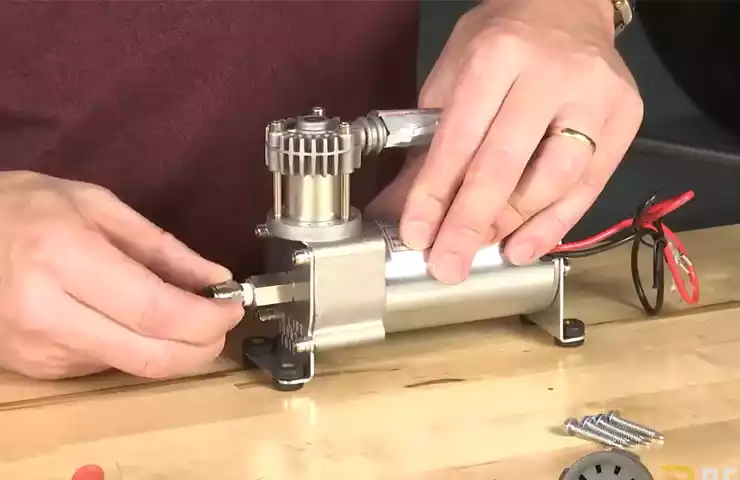

Air compressor

The air compressor is responsible for inflating the air bags. It supplies compressed air to the bags, allowing you to adjust the air pressure as needed. The compressor is usually mounted in a convenient location and is connected to the vehicle’s electrical system for power.

Air lines

The air lines are used to transport the compressed air from the compressor to the air bags. These flexible hoses are constructed to withstand high-pressure air and are designed to be durable and resistant to abrasion. The air lines should be properly routed and secured to ensure efficient and safe operation.

Air fittings

The air fittings are the connectors that join the air lines to the air bags and other components of the system. These fittings are crucial for a leak-free connection and ensure that the compressed air flows smoothly throughout the system. It is important to choose high-quality fittings that are compatible with the air lines and the air bags.

Mounting brackets

The mounting brackets are used to secure the air bags to the vehicle’s suspension. These brackets are specifically designed to fit your vehicle and provide a strong and stable attachment point for the air bags. It is essential to choose the correct mounting brackets to ensure a proper installation and maximize the performance of the air lift air bags.

Hardware

The hardware includes all the necessary nuts, bolts, and other fasteners required for the installation. It is important to use the provided hardware or recommended alternatives to ensure a secure and reliable installation. Using the correct hardware will prevent any potential issues and ensure the longevity of your air lift air bags.

By having these key components for installation, you will be well-prepared to install air lift air bags on your vehicle. Each component plays a crucial role in the overall functionality and performance of the suspension system. Now that you are familiar with the components, let’s move on to the installation process in the next section.

Pre-Installation Preparation

Before beginning the installation process for your Air Lift Air Bags, it is crucial to adequately prepare yourself and your vehicle. Taking the time to complete the necessary pre-installation preparation steps will help ensure a smooth and successful installation. This section will guide you through the essential aspects of pre-installation preparation, including ensuring your vehicle is parked on a level surface, gathering all the necessary tools, and implementing safety precautions.

Ensuring the vehicle is parked on a level surface

Before you can start the installation process, it is imperative to ensure that your vehicle is parked on a level surface. This ensures stability and safety during the installation, allowing you to work comfortably and effectively. Whether you are working in a garage or an open area, take the time to find a level surface for your vehicle to prevent any complications.

Gathering all the necessary tools

Ahead of the installation, gather all the necessary tools and equipment. Having everything you need at hand will streamline the installation process and prevent delays. Here’s a checklist of the tools you’ll likely need:

| Tools | Materials |

|---|---|

| Wrench set | Air Lift Air Bags kit |

| Socket set | Mounting hardware |

| Torque wrench | Teflon tape |

| Jack and jack stands | Electrical connectors (if required) |

Make sure you have all these tools readily available before commencing the installation process. This will save you time and frustration, ensuring a smooth experience.

Safety precautions to keep in mind before starting the installation process

- Wear protective gear, including safety glasses and gloves, to safeguard yourself during the installation process.

- Consult your vehicle’s owner’s manual for any specific safety guidelines and precautions relevant to your vehicle.

- Ensure that the vehicle’s engine is off and the ignition key is removed before starting the installation process.

- Use caution when working with heavy or sharp objects to prevent injuries.

- If you have any doubts regarding the installation process, consult a professional mechanic or seek guidance from the Air Lift Air Bags manufacturer.

Taking these safety precautions will help minimize the risk of injuries and accidents while ensuring a secure and successful installation process.

Installing The Air Lift Air Bag System

Step 1: Mounting the air springs

When it comes to installing the Air Lift Air Bag System, the first step is to mount the air springs. These springs are responsible for providing additional support and stability to your vehicle’s suspension system. Mounting the air springs is a crucial part of the installation process, as it determines the effectiveness of the air bag system. Here’s how you can do it: 1. Begin by locating the mounting brackets included in the Air Lift Air Bag System kit. These brackets are designed to fit specific vehicle models, so make sure you have the right brackets for your vehicle. 2. Identify the correct mounting location for the air springs. This is typically on the axle near the rear suspension. Refer to the installation instructions provided by Air Lift for specific guidance on your vehicle model. 3. Attach the mounting brackets securely to the axle using the provided hardware. Make sure the brackets are aligned properly and tightened to ensure a stable installation. 4. Once the brackets are in place, slide the air springs onto the brackets and secure them using the included hardware. Double-check that the air springs are securely attached and positioned correctly.

Step 2: Connecting the air lines

After mounting the air springs, the next step is to connect the air lines. These lines are responsible for delivering air to the air springs and controlling the amount of pressure in the system. Follow these steps to connect the air lines: 1. Locate the air lines included in the Air Lift Air Bag System kit. These lines are typically color-coded for easy identification. 2. Attach one end of the air line to the air spring. This is usually done by threading the connector onto the air spring valve. 3. Route the air lines along the vehicle’s frame or suspension components, away from potential sources of heat or damage. Use zip ties or clips to secure the lines and prevent them from dangling or rubbing against other parts. 4. Connect the other end of the air lines to the inflation valves provided in the kit. These valves will be used to inflate and deflate the air springs.

Step 3: Installing the compressor and control system

After connecting the air lines, it’s time to install the compressor and control system. These components allow you to control the air pressure in the air springs, providing you with the ability to adjust the ride height and stiffness. Follow these steps to install the compressor and control system: 1. Locate a suitable location for the compressor. This can vary depending on your vehicle’s make and model, but it is typically mounted in the engine bay or under the vehicle. 2. Attach the compressor securely using the provided brackets and hardware. Make sure it is mounted in a position that allows for easy access and protection from potential damage. 3. Install the control system components, such as the control panel and pressure switch, in a convenient and accessible location within the vehicle’s cabin. It’s important to choose a location that allows for easy operation while driving. 4. Route the necessary wiring from the compressor and control system to their respective locations. This may involve drilling holes and using grommets to protect the wiring from chafing.

Step 4: Wiring the compressor and control system

With the compressor and control system installed, the next step is to wire them properly to ensure their functionality. Here’s how you can do it: 1. Connect the power wire from the compressor to a suitable power source, such as the vehicle’s battery. Use the provided fuse holder and appropriate gauge wire for a safe and secure connection. 2. Connect the control panel and pressure switch to the control system’s wiring harness. Follow the provided wiring diagram to ensure the correct connections are made. 3. Route the wiring from the control panel and pressure switch to the compressor. Secure the wiring along the vehicle’s frame or existing wiring harnesses, using zip ties or clips to prevent it from moving or rubbing against other parts. 4. Test the wiring connections by turning on the control panel and checking that the compressor operates as intended. If there are any issues, double-check the wiring connections and consult the installation instructions for troubleshooting guidance.

Step 5: Testing the installation for any leaks or issues

After completing the installation of the Air Lift Air Bag System and wiring, it’s important to test the installation for any leaks or issues. Here’s what you should do: 1. Inflate the air springs gradually using the control panel. Monitor the air pressure and check for any leaks around the air springs, air lines, and connections. Apply a soapy water solution to identify any air bubbles, which indicate a leak. 2. If you detect a leak, inspect the affected area and tighten the connections as necessary. Reapply the soapy water solution to confirm that the leak has been resolved. 3. Once the air springs are inflated, visually inspect the entire installation to ensure that all components are secured and functioning correctly.

Step 6: Adjusting the air pressure to achieve desired results

The final step in installing the Air Lift Air Bag System is adjusting the air pressure to achieve the desired results. Here’s what you need to do: 1. Refer to the owner’s manual or manufacturer’s recommendations for the recommended air pressure for your vehicle and specific application. This information will guide you in adjusting the pressure of your air springs. 2. Use the control panel to increase or decrease the air pressure in the air springs. Make small adjustments and evaluate the vehicle’s ride and handling characteristics after each adjustment. 3. Test the vehicle under different load conditions to determine the optimal air pressure that provides the desired level of support and comfort. Keep in mind that proper adjustment of the air pressure may require some trial and error. Take the time to fine-tune the pressure until you achieve the best results for your specific needs. By following these six steps, you can successfully install the Air Lift Air Bag System and enjoy the benefits of improved suspension support and ride quality in your vehicle. Remember to consult the specific installation instructions included with your kit for any additional guidance or vehicle-specific requirements.

Maintenance And Troubleshooting Tips

Proper maintenance practices to prolong the lifespan of air lift air bags

Proper maintenance is essential for ensuring the longevity and optimal performance of your air lift air bags. By following these maintenance practices, you can significantly extend the lifespan of your air bags and avoid unnecessary issues down the road.

- Inspect the air bags regularly: Perform visual inspections at regular intervals to check for any signs of damage or wear. Look for punctures, leaks, or signs of sagging. If any issues are detected, it’s important to address them promptly.

- Keep the air bags clean: Debris, dirt, and dust can accumulate on the air bags and impact their performance. Regularly clean the air bags using mild soap and water. Avoid using harsh chemicals or abrasive scrubbing tools that could damage the bags.

- Check air pressure levels: Monitoring the air pressure in the air bags is crucial for maintaining their functionality. Use a pressure gauge to check the pressure and ensure it is within the recommended range. Fill or deflate the air bags as needed.

Common troubleshooting issues and how to resolve them

Even with proper maintenance, occasional issues may arise with air lift air bags. Knowing how to troubleshoot these problems can save you time and money. Here are some common troubleshooting issues and their solutions:

- Uneven leveling: If one side of your vehicle appears higher or lower than the other, it could indicate an uneven leveling issue. Start by examining the air lines and fittings for any leaks or loose connections. Make sure the air bags are properly inflated. If the problem persists, it may be necessary to consult a professional for further inspection and adjustment.

- Excessive air loss: If you notice a significant loss of air pressure in a short period, it could indicate a leak in the air bags. Check all connections and fittings for any signs of leaks. Apply a soap and water solution to identify any escaping air, indicated by bubbles forming. Once located, repair or replace the damaged component accordingly.

- Abnormal noises: Unusual sounds like hissing or squeaking during air bag operation may indicate a problem. Inspect the air bags, brackets, and mounting hardware for any signs of damage or looseness. Lubricate moving parts as necessary. If the noise persists, seek professional assistance to identify and resolve the issue.

Remember, proper maintenance and timely troubleshooting are key to ensuring the optimal performance and longevity of your air lift air bags. By following these guidelines and addressing any issues promptly, you can enjoy a smooth and worry-free towing experience.

Frequently Asked Questions For How To Install Air Lift Air Bags

How Hard Is It To Install Air Lift?

Installing Air Lift is relatively easy. The process is straightforward and doesn’t require advanced technical skills. With basic tools and instructions, you can do it in a few hours.

Can You Install Airbags With A Lift Kit?

No, it is not recommended to install airbags with a lift kit. Airbags are designed to work within the factory suspension system, and altering the suspension with a lift kit can affect their functionality and effectiveness.

How Much Does It Cost To Install An Air Lift?

The cost of installing an Air Lift varies, depending on the vehicle and the specific Air Lift system selected. Factors such as the complexity of the installation and any additional components can also affect the price. It is recommended to consult with a professional installer or contact the Air Lift manufacturer for an accurate quote.

What Is The Max Psi For Air Lift Air Bags?

The max PSI for Air Lift air bags can vary between 100 to 150 PSI.

Conclusion

Installing air lift air bags is a straightforward process that can provide numerous benefits to your vehicle’s suspension and towing capabilities. By following the step-by-step instructions outlined in this blog post, you can enhance your vehicle’s stability, control, and overall performance.

Whether you are hauling heavy loads or simply looking for a more comfortable ride, air lift air bags can be a valuable addition to your vehicle. So, don’t hesitate to install them and enjoy the advantages they have to offer!