To install air bag suspension on a truck, start by finding the appropriate air bag kit and necessary tools. Then, follow the manufacturer’s instructions to mount the air bags, connect the air lines, and install the control system.

Adjust the air pressure according to the desired ride height. Regularly inspect and maintain the system for optimal performance.

Understanding The Benefits Of Air Bag Suspension

When it comes to upgrading your truck’s suspension system, air bag suspension is a popular choice among truck enthusiasts. Understanding the benefits of air bag suspension can help you determine if it’s the right choice for your vehicle. In this article, we’ll explore why you should choose air bag suspension over traditional suspension systems, highlighting its increased load-carrying capacity and improved stability and control while towing.

Why choose air bag suspension over traditional suspension systems

Air bag suspension offers a range of advantages over traditional suspension systems. Here are some key reasons why you should consider this innovative suspension technology:

- **Improved ride quality:** Air bag suspension provides a smoother and more comfortable ride, reducing the impact of bumps and shocks during your journeys.

- **Adjustable ride height:** With air bag suspension, you have the ability to adjust the ride height of your truck. This feature allows you to customize your vehicle’s stance and adapt it for different driving conditions.

- **Enhanced safety:** Air bag suspension helps improve the overall safety of your truck. By maintaining a level ride, it reduces the risk of body roll, improves braking performance, and enhances vehicle stability.

Increased load-carrying capacity

One of the primary benefits of air bag suspension is its increased load-carrying capacity. Traditional suspension systems can struggle to handle heavy loads, resulting in sagging and compromised handling. Air bag suspension, on the other hand, provides additional support and helps distribute the weight evenly across all four corners of your truck.

By installing air bags, you can easily adjust the air pressure according to the load you’re carrying. Whether you’re hauling heavy equipment for work or embarking on a camping trip with a lot of gear, air bag suspension ensures that your truck remains level and stable, regardless of the weight it’s carrying.

Improved stability and control while towing

Towing a trailer can be challenging, especially when it comes to maintaining stability and control. Air bag suspension can greatly improve your towing experience by increasing stability and reducing swaying or bouncing.

When towing heavy loads, air bag suspension helps to level your truck and eliminate the sag that can occur with traditional suspension systems. This improved stability and control translate to safer and more controlled towing, allowing you to confidently navigate corners, handle sudden maneuvers, and experience less fatigue while on the road.

In conclusion, air bag suspension offers a range of benefits that can significantly enhance your truck’s performance, safety, and comfort. With its increased load-carrying capacity and improved stability and control while towing, it’s no wonder why many truck owners are choosing air bag suspension over traditional suspension systems.

Preparing Your Truck For Air Bag Suspension Installation

Before you can start installing air bag suspension on your truck, it’s important to properly prepare your vehicle. This involves choosing the right air bag suspension kit, gathering the necessary tools and materials, and ensuring the safety of both yourself and your truck.

Choosing the right air bag suspension kit for your truck

The first step in preparing your truck for air bag suspension installation is to choose the right kit. This decision depends on various factors like the make and model of your truck, its weight, and the level of adjustability you desire for your suspension. It’s vital to select a kit that is compatible with your specific truck to ensure optimal performance and a smooth ride.

Gathering the necessary tools and materials

Once you have determined the suitable air bag suspension kit for your truck, it’s time to gather all the necessary tools and materials. Here is a list of items you will typically need:

| Tools | Materials |

| – Jack and jack stands | – Air bag suspension kit |

| – Socket set | – Air compressor |

| – Wrenches | – Air lines and fittings |

| – Screwdrivers | – Mounting brackets |

| – Torque wrench | – Electrical connections |

It’s important to ensure that you have all the necessary tools and materials before you begin the installation process. This will help prevent any delays or interruptions during the installation.

Elevating the truck and ensuring proper safety precautions

Before you install air bag suspension on your truck, you need to elevate the vehicle and take proper safety precautions. Follow these steps to do so:

- Find a level and solid surface to work on.

- Use a jack to lift the truck off the ground. Make sure to lift it high enough to have sufficient working space underneath.

- Place jack stands securely under the truck to provide additional support.

- Double-check that the truck is stable and will not move or fall during the installation process.

By elevating your truck and taking these safety precautions, you can ensure a safe and stable working environment during the installation process.

Step-By-Step Guide To Installing Air Bag Suspension

Installing air bag suspension on a truck can greatly improve its stability, control, and towing capacity. This step-by-step guide will walk you through the process of installing air bag suspension, ensuring a smooth installation and optimal performance. In this guide, you will learn how to remove the existing suspension components, install the air bags and brackets, connect the air lines and valves, mount the compressor and control system, wire the electrical connections, and test and adjust the air bag suspension. Let’s dive in and get started!

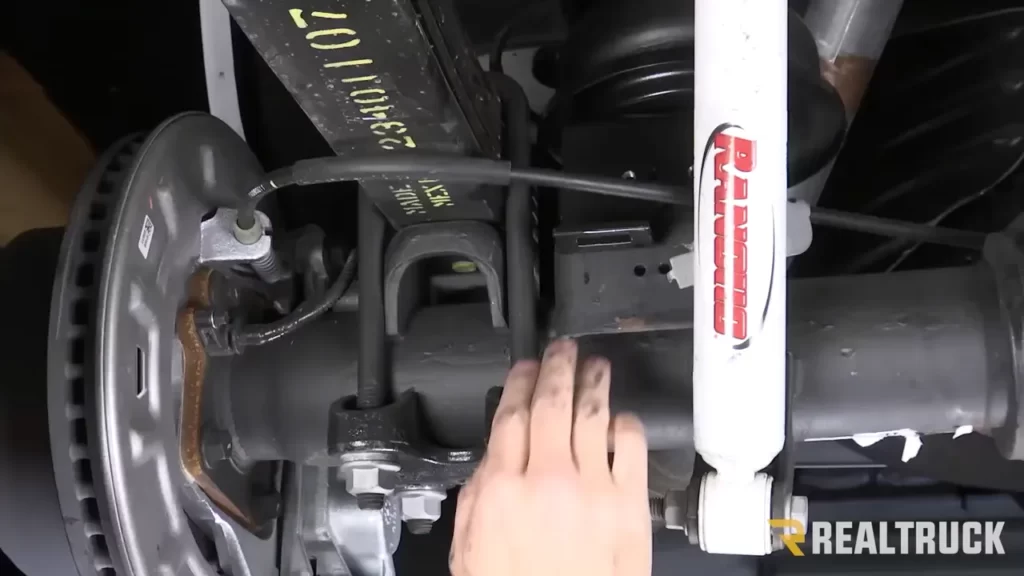

Removing the existing suspension components

The first step in installing air bag suspension on your truck is to remove the existing suspension components. This includes removing the leaf springs, shocks, and any other components that are part of the original suspension system. Follow these steps to remove the existing suspension components:

- Support the truck on jack stands and ensure it is secure.

- Use a wrench or socket set to remove the bolts that attach the leaf springs to the frame of the truck.

- Lower the axle of the truck to relieve tension on the leaf springs.

- Remove the shocks by loosening the bolts at the top and bottom.

- Once all the components are removed, inspect the frame for any signs of damage or wear. This is also a good time to clean the frame and prepare it for the installation of the air bags and brackets.

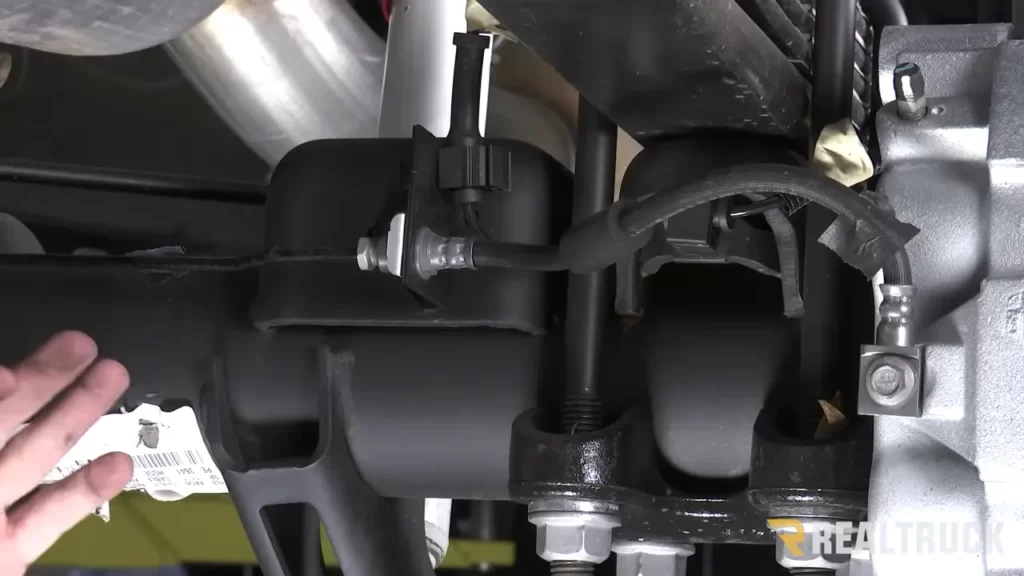

Installing the air bags and brackets

With the existing suspension components removed, it’s time to install the air bags and brackets. These will serve as the main support system for the air bag suspension. Follow these steps to install the air bags and brackets:

- Position the air bags and brackets on the truck’s frame, ensuring they are centered and aligned properly.

- Secure the brackets to the frame using the provided hardware and a wrench or socket set.

- Attach the air bags to the brackets using the provided hardware and a wrench or socket set.

- Ensure that the air bags are securely in place and aligned with the brackets.

Connecting the air lines and valves

Once the air bags and brackets are installed, it’s time to connect the air lines and valves. These will allow you to control the air pressure in the air bags and adjust the suspension as needed. Follow these steps to connect the air lines and valves:

- Run the air lines from the air bags to the desired location of the valves. This can be anywhere inside the cab of the truck or in a more accessible location.

- Connect the air lines to the valves, ensuring a secure and tight connection.

- Mount the valves in the desired location using the provided hardware and a wrench or socket set.

- Ensure that the valves are easily accessible for adjusting the air pressure.

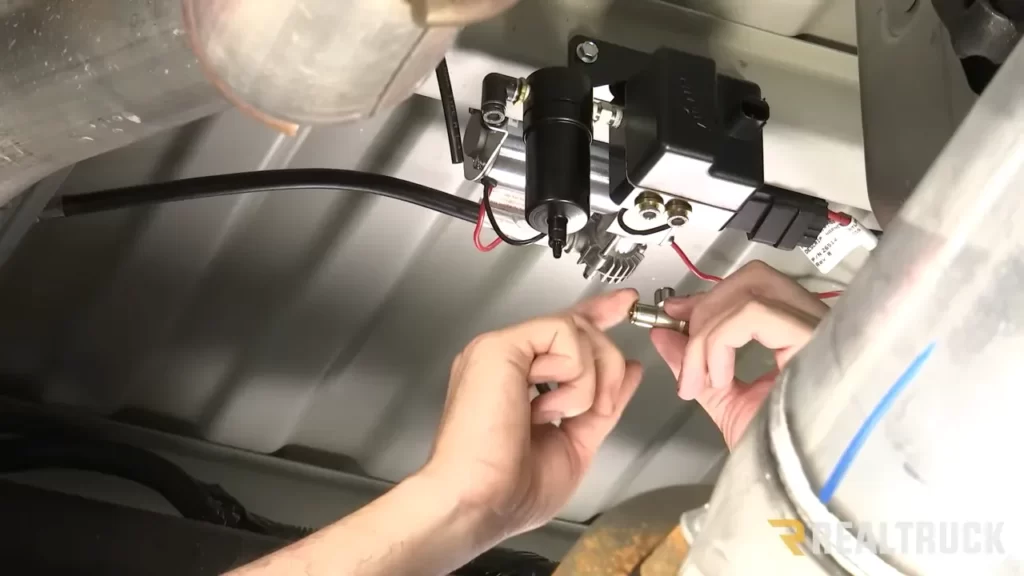

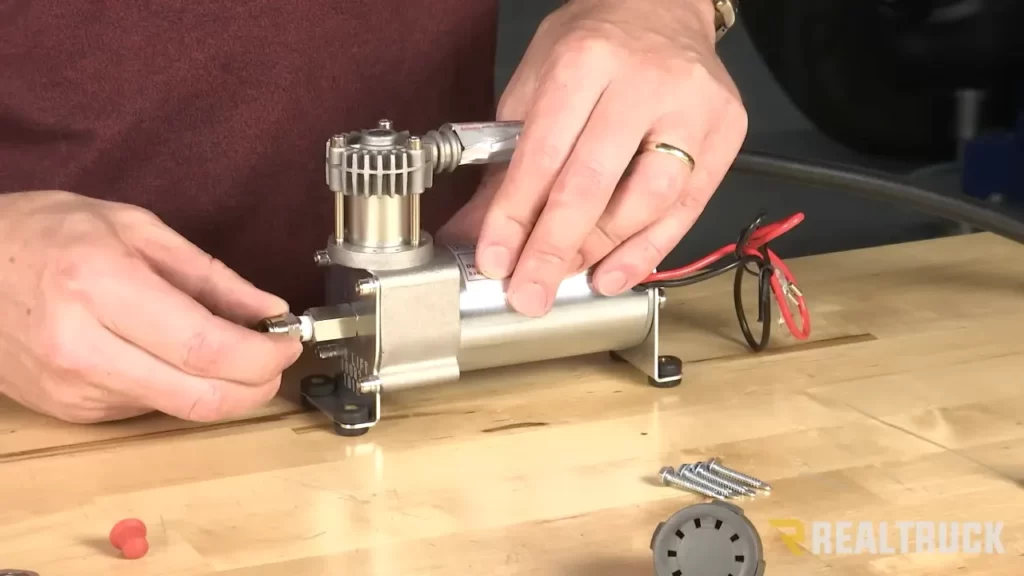

Mounting the compressor and control system

In order to inflate and deflate the air bags, a compressor and control system must be mounted on the truck. Follow these steps to mount the compressor and control system:

- Select a suitable location for mounting the compressor and control system. This can be under the hood, inside the cab, or anywhere else that is easily accessible.

- Secure the compressor and control system to the chosen location using the provided hardware and a wrench or socket set.

- Ensure that the compressor and control system are safely mounted and positioned for easy operation.

Wiring the electrical connections

In order for the compressor and control system to function properly, the electrical connections must be wired correctly. Follow these steps to wire the electrical connections:

- Identify the power source for the compressor and control system. This can be the truck’s battery or another power source.

- Connect the positive and negative wires from the compressor and control system to the power source, ensuring proper polarity.

- Secure the wires using the provided connectors or electrical tape.

- Test the electrical connections to ensure proper functionality.

Testing and adjusting the air bag suspension

Once the air bag suspension is fully installed, it’s important to test and adjust it to ensure optimal performance. Follow these steps to test and adjust the air bag suspension:

- Start the truck and let it idle.

- Monitor the inflation and deflation of the air bags as you adjust the air pressure using the valves.

- Observe how the truck’s ride height and stability change with different air pressure settings.

- Make adjustments as necessary until you achieve the desired ride height and performance.

Congratulations! You have successfully installed air bag suspension on your truck. Enjoy the improved stability, control, and towing capacity that air bag suspension provides!

Maintenance And Troubleshooting Tips For Air Bag Suspension

Proper maintenance and regular inspections are crucial for ensuring the optimal performance and longevity of your truck’s air bag suspension system. By following these maintenance and troubleshooting tips, you can keep your air bags and components in excellent condition and avoid potential issues that may arise. In this section, we will discuss the importance of regular inspection and cleaning of air bags and components, checking air pressure and making adjustments as needed, as well as troubleshooting common issues such as leaks or uneven inflation.

Regular Inspection and Cleaning of Air Bags and Components

Regularly inspecting your air bags and components is vital to identify any potential problems or signs of wear and tear. Here are some steps to follow:

- Start by visually inspecting the air bags, air lines, and fittings for any signs of damage, such as cracks, tears, or leaks.

- Check the mounting brackets and ensure they are secure and free from any corrosion.

- Inspect the air valves and make sure they are properly seated and not damaged.

- If you notice any dirt or debris on the air bags, clean them gently with a mild soap and water solution. Avoid using harsh chemicals or abrasives that may damage the bags.

- After cleaning, dry the air bags thoroughly before reinstalling them.

Checking Air Pressure and Adjusting as Needed

Maintaining the appropriate air pressure in your air bags is crucial for optimal performance. Here’s how you can check the air pressure and make adjustments:

- Start by parking your truck on a level surface and ensure the suspension is completely unloaded.

- Locate the air valves on each air bag, usually near the top or bottom.

- Carefully remove the valve caps and attach a pressure gauge to each valve.

- Read the pressure shown on the gauge. Compare it to the manufacturer’s recommended pressure.

- If the pressure is too high, release some air by gently depressing the center pin in the valve with a small tool.

- If the pressure is too low, add air using an air compressor or a portable air tank until the desired pressure is reached. Avoid overinflating the air bags.

- Once you have adjusted the air pressure, reattach the valve caps securely.

Troubleshooting Common Issues

Occasionally, you may encounter common issues with your air bag suspension system. Here are some troubleshooting tips:

Leaks:

- If you suspect a leak, start by inspecting all air lines and fittings for visible signs of air escaping.

- Apply a soapy water solution to suspect areas and look for bubbles, which indicate a leak.

- If you locate a leak, replace the damaged component immediately to prevent further issues.

Uneven Inflation:

- If your truck’s suspension is experiencing uneven inflation, one possible cause could be a faulty air valve.

- Inspect the valves for any signs of damage, such as cracks or loose connections.

- If necessary, replace the faulty valve to restore proper inflation.

By following these maintenance and troubleshooting tips, you can ensure that your air bag suspension system operates smoothly and provides the support and comfort you need for your truck. Regular inspections, cleaning, and adjustments play a vital role in maximizing the lifespan of your air bags and components, as well as preventing potential issues from escalating into major problems.

Enhancing Your Truck’S Performance And Comfort With Air Bag Suspension

Adjusting the air pressure for various loads and road conditions

One of the major advantages of installing air bag suspension on your truck is the ability to easily adjust the air pressure according to the specific load and road conditions. Whether you’re carrying a heavy load or driving on rough terrain, being able to fine-tune the air pressure in your suspension system allows for a customizable and controlled ride. Adjusting the air pressure is a straightforward process that can be done using a pressure gauge and an air compressor.

Improving ride quality and reducing body roll

With air bag suspension, you can significantly improve the ride quality of your truck. Air bags provide a cushioning effect that absorbs the shocks and vibrations from the road, resulting in a smoother and more comfortable ride. By reducing the harshness of bumps and dips, air bag suspension helps minimize the impact felt by both the truck and its occupants.

Air bag suspension also plays a crucial role in reducing body roll, especially during turns and cornering. The air bags help stabilize the truck by maintaining an even distribution of weight, thereby reducing the risk of swaying or tilting. This not only enhances the overall handling and stability of the truck but also promotes safer driving.

Upgrading to electronic suspension controls and accessories

When it comes to maximizing the performance and convenience of your air bag suspension, upgrading to electronic suspension controls and accessories is a game-changer. Electronic controls allow you to adjust the air pressure on the go, without the need for manual intervention. This means you can easily adapt your suspension system to varying loads and road conditions without having to stop and make adjustments.

Additionally, electronic suspension controls often come with extra features and accessories that further enhance the functionality and customization of your air bag suspension. This may include features like automatic leveling, which ensures that your truck remains level regardless of the load, or wireless remote control, which allows you to adjust the air pressure from inside the cabin.

With these electronic upgrades, you can experience a whole new level of convenience, comfort, and control with your air bag suspension. Say goodbye to the hassle of manual adjustments and enjoy the benefits of a fully optimized suspension system.

Frequently Asked Questions For How To Install Air Bag Suspension On Truck

Can You Install Airbag Suspension Yourself?

Yes, you can install airbag suspension yourself with the right knowledge and tools. It’s important to follow instructions carefully and have experience working on vehicles. Hiring a professional may be a safer option if you’re unsure or lack expertise. Safety should be a top priority when installing airbag suspension.

How Much Does It Cost To Put Airbag Suspension In A Truck?

The cost of putting airbag suspension in a truck can vary. Factors such as the type and brand of the system, installation fees, and additional components can affect the overall price. It is best to consult with a professional or contact a specialized shop for an accurate quote.

How Much Does It Cost To Install An Airbag?

The cost of installing an airbag can vary depending on several factors, such as the make and model of the vehicle. On average, the installation cost can range anywhere from $100 to $500. It is recommended to consult with a certified technician for an accurate estimate tailored to your specific vehicle.

How Long Does It Take To Install An Air Bag Suspension?

The installation of an air bag suspension typically takes around six to eight hours, depending on the complexity of the system and the experience of the installer.

Conclusion

In the final analysis, adding air bag suspension to your truck is a practical and effective way to enhance its performance and versatility. By following the step-by-step instructions outlined in this guide, you can successfully install air bag suspension and enjoy a smoother ride, improved towing capacity, and better overall control.

Don’t hesitate to give your truck the upgrade it deserves and experience the benefits firsthand.