Installing a TXV involves a step-by-step process: first, gather the necessary tools and materials; second, shut off the power to the air conditioner; third, remove the existing expansion valve; fourth, install the new TXV in the correct position; fifth, reconnect the refrigerant lines and electrical connections; and finally, test the system for proper function. This article provides a comprehensive guide to installing a TXV in your air conditioning system, ensuring efficient and correct installation.

Read on to learn how to successfully install a TXV and improve the performance of your AC unit.

Understanding The Txv And Its Importance

When it comes to ensuring optimal performance of your HVAC system, understanding the Txv (thermostatic expansion valve) is crucial. The Txv plays a vital role in regulating the flow of refrigerant in your system, ensuring efficient cooling or heating. In this blog post, we will dive into the significance of the Txv, its key components, and the importance of proper installation for optimal performance.

What is a Txv and why is it used?

A Txv is a device that controls the amount of refrigerant flow entering the evaporator coil of your HVAC system. It acts as a metering device that automatically adjusts the refrigerant flow, based on the cooling load or demand from the conditioned space. This sophisticated valve ensures that the right amount of refrigerant is circulated, preventing undercooling or overcooling of the space.

The Txv uses a temperature-sensitive bulb and a diaphragm to regulate the flow of refrigerant. The bulb senses the evaporator coil’s temperature and signals the valve to open or close accordingly. By maintaining the proper superheat, the Txv prevents the evaporator coil from freezing and maximizes the heat transfer process.

Key components of a Txv system

A Txv system comprises several key components that work together to regulate the flow of refrigerant. These components include:

- Txv Valve Body: The valve body houses the internal components of the Txv and controls the refrigerant flow rate.

- Powerhead: The powerhead consists of a diaphragm and a temperature-sensitive bulb. It receives the signal from the bulb and modulates the flow of refrigerant.

- Equalizer Tube: This tube connects the outlet of the evaporator coil to the valve body. It equalizes the pressure across the evaporator coil, ensuring an even flow of refrigerant.

- Adjustment Screw: The adjustment screw allows fine-tuning of the Txv’s superheat setting, optimizing its performance for specific applications.

It’s important to note that the Txv system can vary depending on the HVAC manufacturer and model. Therefore, it’s crucial to refer to the manufacturer’s instructions and specifications during installation.

Importance of proper installation for optimal performance

Proper installation of the Txv is paramount to ensure optimal performance and energy efficiency of your HVAC system. When the Txv is installed correctly, it helps maintain the desired temperature, prevents temperature fluctuations, and reduces energy consumption.

An improperly installed Txv can lead to a range of issues, such as insufficient cooling, uneven temperature distribution, increased energy usage, and premature wear and tear of the system components. This highlights the importance of hiring a professional HVAC technician who has the knowledge and expertise to install the Txv correctly.

During installation, the technician must ensure that the Txv is sized appropriately for the HVAC system, positioned correctly, and has the right refrigerant charge. Additionally, they should follow the manufacturer’s guidelines to connect and adjust the Txv and other components accurately.

Regular maintenance and inspections are also essential to keep the Txv functioning optimally. By checking for any leaks, cleaning the valve body, and verifying the superheat, technicians can identify and resolve any issues that may affect the Txv’s performance.

In conclusion, understanding the Txv and ensuring its proper installation are key to maintaining the optimal performance and energy efficiency of your HVAC system. The Txv’s ability to regulate the refrigerant flow helps achieve consistent and comfortable indoor temperatures while minimizing energy consumption. So, be sure to rely on a professional HVAC technician to install and maintain your Txv system, ensuring its longevity and optimal functionality.

Gathering The Necessary Tools And Materials

If you’re planning to install a TXV (Thermostatic Expansion Valve) for your HVAC system, it’s crucial to gather the right tools and materials beforehand. This ensures a smooth installation process and guarantees the best performance from your new TXV. In this section, we’ll discuss the tools required for TXV installation, the materials needed for a successful installation, and the importance of choosing the right tools and materials.

Tools required for TXV installation

Before you begin the installation process, make sure you have the following tools at your disposal:

| Tool | Description |

|---|---|

| Screwdriver set | A set of screwdrivers in varying sizes to handle different screws and fasteners. |

| Adjustable wrench | A wrench that can be adjusted to fit different sizes of nuts and bolts. |

| Tube cutter | A tool used to cut copper tubes cleanly and accurately. |

| Flaring tool | Used to create a flare on the end of a copper tube for secure connections. |

| Torches | Either a propane torch or an MAPP gas torch to heat and solder copper tubes. |

| Manifold gauge set | A tool to measure pressure and temperature in the HVAC system. |

Materials needed for a successful installation

In addition to the tools, you’ll also need the following materials to ensure a successful TXV installation:

- TXV kit – Includes the TXV valve, bulb, and other necessary components.

- Copper tubing – Provides a durable and efficient conduit for refrigerant flow.

- Refrigerant – The specific type recommended for your HVAC system, usually R-410A or R-22.

- Flux – A substance applied to copper tubing joints for a secure soldered connection.

- Solder – Used to join copper tubing and create a leakage-free connection.

- Insulation tape – Wraps around the refrigerant lines to prevent condensation and energy loss.

- Leak detector – A tool used to detect and locate refrigerant leaks.

Importance of choosing the right tools and materials

Choosing the appropriate tools and materials for your TXV installation is of utmost importance. Using the right tools ensures that you can effectively dismantle the old valve, make accurate cuts on the copper tubing, and create secure connections without damaging any components. Likewise, selecting the proper materials guarantees that your HVAC system operates efficiently and reliably. Using the recommended refrigerant, for example, prevents compatibility issues that could lead to system malfunctions or reduced cooling performance.

Moreover, using quality materials, such as copper tubing and insulation tape, contributes to the longevity of your installation. Copper tubing offers superior durability, effectively withstands high pressures, and minimizes refrigerant leakage. Meanwhile, insulation tape prevents energy loss by reducing heat exchange between the refrigerant lines and the surrounding environment. Taking the time to choose the right tools and materials ensures a successful TXV installation and optimal performance from your HVAC system.

Preparing For Installation

Before you begin installing a TXV (thermostatic expansion valve) for your HVAC system, it is important to properly prepare for the installation process. This step ensures a smooth and successful installation, minimizing any potential risks or issues that may arise. In this section, we will cover the necessary steps to understand the system layout, shut off the power and gas supply, remove the old TXV (if applicable), and clean and inspect the system components.

Understanding the system layout

It is crucial to have a clear understanding of your HVAC system’s layout before installing a TXV. Start by familiarizing yourself with the different components of the system, such as the condenser unit, evaporator coil, and refrigerant lines. Identifying these elements will help you pinpoint the location of the TXV and determine the appropriate steps for installation.

Shutting off the power and gas supply

Prior to any HVAC related work, it is important to disconnect the system from its power source. Locate the main electrical panel and switch off the circuit breaker that supplies power to the HVAC unit. Additionally, if your system is connected to a gas supply, make sure to turn off the gas valve. These precautionary measures ensure the safety of both the installer and the system.

Removing the old TXV (if applicable)

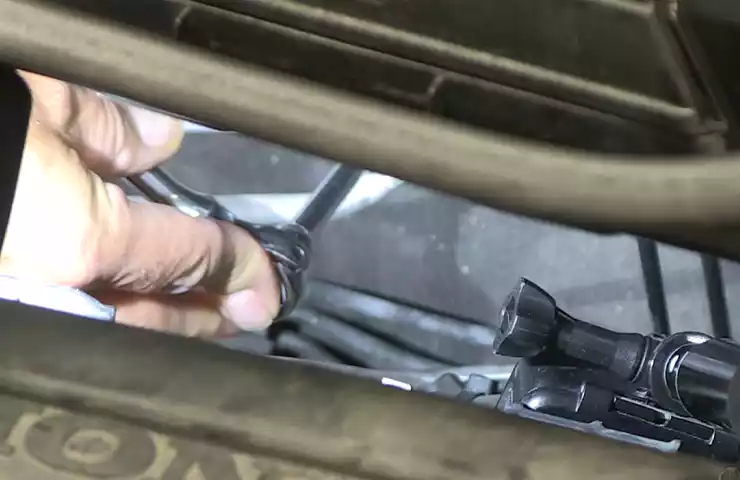

If you are replacing an existing TXV, carefully remove the old valve from the system. Begin by loosening the flare fittings or threaded connections that secure the TXV to the refrigerant lines. Use appropriate tools, such as wrenches or pliers, to disconnect the valve. Take note of the position and orientation of the old TXV, as it will be helpful during the installation of the new one.

Cleaning and inspecting the system components

Prior to installing the new TXV, it is essential to clean and inspect the system components. Use a soft brush or cloth to remove any dust, debris, or dirt that may have accumulated on the coils, fins, and other parts of the system. Inspect visually for any signs of damage or wear, such as bent fins or leaks in the refrigerant lines. Cleaning and inspecting the system components ensures optimal performance and prolongs the lifespan of the new TXV.

Installing The Txv

Installing the Txv When it comes to installing a thermal expansion valve (Txv) in your HVAC system, it is important to follow the proper steps to ensure it is positioned correctly and connected securely. In this section, we will walk you through the process of installing the Txv, step by step.

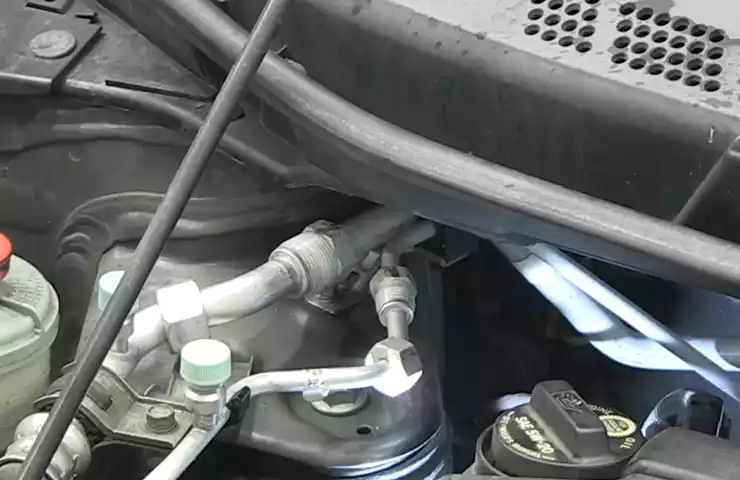

Positioning the new Txv in the system

The first step in installing the Txv is to position it correctly within the HVAC system. This valve should be located at the evaporator coil outlet, where it will regulate the flow of refrigerant into the coil. To find the proper location, refer to the manufacturer’s instructions or consult with a professional technician.

Connecting the Txv to the refrigerant line

Once you have determined the correct placement, it’s time to connect the Txv to the refrigerant line. Begin by cutting the refrigerant line at the desired location, ensuring that you have enough space to accommodate the valve. Use a tubing cutter to make a clean, precise cut. Next, attach the flare nut to the tubing, making sure it is tight and secure. Slide the compression sleeve onto the tubing, followed by the flare ferrule. Now, connect the tubing to the Txv by sliding the nut over the valve’s outlet and tightening it until it is snug.

Securing the Txv in place and ensuring proper fit

With the Txv connected, it is essential to secure it in place and ensure a proper fit. Use zip ties or metal straps to fasten the valve to the surrounding components, such as the coil or nearby piping. This will prevent any unwanted movement or vibration that could damage the Txv or affect its performance. Additionally, confirm that the Txv is properly aligned with the refrigerant line and other connections. Check for any gaps or misalignments and make adjustments as necessary. A snug and secure fit is crucial for the smooth operation of the Txv.

Reconnecting any electrical and gas connections

The final step in installing the Txv involves reconnecting any electrical and gas connections that were disconnected during the process. This may include reconnecting wires to the valve’s solenoid or other electrical components, as well as attaching any gas lines that were disconnected. When reconnecting electrical connections, ensure that each wire is properly secured and insulated. Take care to follow the manufacturer’s guidelines and wiring diagrams to prevent any potential electrical hazards. For gas connections, utilize proper tools and fittings to ensure a tight and leak-free seal. In conclusion, installing a Txv requires precise positioning, secure connections, and proper fit within the HVAC system. By following the steps outlined above, you can successfully install a new Txv and ensure the efficient and reliable operation of your HVAC system.

Testing And Adjusting The Txv

Once you have successfully installed a thermostatic expansion valve (Txv) in your HVAC system, the next crucial step is to test and adjust it to ensure optimal performance. Testing and adjusting the Txv involves several key processes, including checking for leaks in the system, fine-tuning the Txv for maximum efficiency, and thoroughly testing the system’s cooling and heating capabilities. In this section, we will walk you through each of these steps to ensure that your HVAC system is functioning at its best.

Checking for leaks in the system

Before proceeding with any adjustments or testing, it is essential to check for potential leaks in the HVAC system. Even the smallest leakage can compromise the performance of the Txv and lead to inefficiency and increased energy consumption. To check for leaks:

- Inspect all the connections and joints in the system, including the tubing, fittings, and valves.

- Apply a mixture of soap and water to the suspected areas.

- Observe for any bubbles or foam formation, as it indicates a leak.

- If a leak is detected, determine the exact location and promptly repair or replace the faulty component, ensuring a tight seal.

Adjusting the Txv for optimal performance

Now that you have confirmed that your system is free from leaks, it’s time to fine-tune the Txv for optimal performance. Here is a step-by-step guide on how to adjust the Txv:

- Start by using a pressure gauge to measure the system’s refrigerant pressure.

- Compare the measured pressure with the manufacturer’s recommended pressure range.

- If the pressure is too high, adjust the superheat setting of the Txv to decrease the refrigerant flow and reduce pressure.

- If the pressure is too low, increase the superheat setting to allow more refrigerant flow and raise the pressure.

- Make small adjustments at a time, and recheck the pressure after each adjustment until it falls within the desired range.

- Monitor the system’s performance and make further adjustments if necessary to achieve optimal cooling or heating efficiency.

Testing the system’s cooling and heating capabilities

Once you have properly adjusted the Txv, it’s essential to test the system’s cooling and heating capabilities to ensure everything is functioning as expected. Here’s how:

- Set the thermostat to the desired cooling temperature and let the system run for a sufficient time to achieve a steady-state condition.

- Observe and note the cooling temperature at various points in the system, such as supply and return vents.

- Repeat the above process for heating by setting the thermostat to the desired heating temperature.

- Compare the observed temperatures with the desired set points and assess if they match your expectations.

If the cooling or heating temperatures do not meet the desired set points, further adjustments may be needed to optimize the system’s performance.

By following these testing and adjusting procedures, you can ensure that your Txv and HVAC system are working efficiently and providing optimal cooling and heating capabilities. Regular maintenance and periodic checks are vital to keep your system running smoothly and minimize energy wastage.

Ensuring Proper Functionality

Once you have successfully installed a TXV (Thermal Expansion Valve) in your HVAC system, it is crucial to ensure its proper functionality. This will help optimize the overall performance of your system and enhance its efficiency. By monitoring the system’s performance, identifying any issues or discrepancies, and troubleshooting and resolving common TXV installation problems, you can ensure that your HVAC system operates smoothly and efficiently.

Monitoring the system’s performance after installation

To ensure the proper functionality of the installed TXV, it is important to monitor the performance of your HVAC system. This can be done by observing various factors that indicate the optimal performance of the system. Keep an eye on:

- The temperature of the cooled or heated air coming out of the vents.

- The pressure levels within the system, ensuring they are within the recommended range.

- Energy consumption, comparing it to previous records if available.

- The time taken to reach the desired temperature or the duration of the operating cycles.

Identifying any issues or discrepancies

While monitoring the system’s performance, it is essential to identify any issues or discrepancies that may arise. These issues can affect the proper functionality of the TXV and the overall performance of the HVAC system. Look out for the following indicators:

- Uneven cooling or heating throughout your home or building.

- Excessive noise coming from the HVAC unit.

- Fluctuating pressure levels that are outside the recommended range.

- Inaccurate temperature readings from your thermostat.

Troubleshooting and resolving common TXV installation problems

If you encounter any issues or discrepancies with your TXV installation, it is important to troubleshoot and resolve these problems promptly. Here are some common problems that you may come across:

| Problem | Possible Solution |

|---|---|

| TXV not providing adequate refrigerant flow | Check for any obstructions or blockages in the TXV or refrigerant lines. Adjust the TXV’s superheat setting if necessary. |

| TXV stuck in an open or closed position | Inspect the TXV for any mechanical issues or debris. Clean or replace the faulty TXV if needed. |

| TXV causing excessive system cycling | Verify that the TXV’s sensing bulb is correctly positioned and insulated. Check for any refrigerant leaks and repair them. |

By troubleshooting and resolving these common problems, you can ensure that your TXV installation functions properly and optimizes your HVAC system’s performance.

Ensuring the proper functionality of your TXV installation is crucial for the overall efficiency of your HVAC system. By monitoring the system’s performance, identifying any issues or discrepancies, and promptly troubleshooting and resolving common TXV installation problems, you can enjoy a well-functioning HVAC system that provides optimal cooling or heating for your home or building.

Maintaining And Servicing The Txv

Regular maintenance and servicing are crucial for keeping the Txv system in optimal condition and ensuring its peak performance. By following simple maintenance tasks and periodically cleaning and inspecting the Txv, you can extend its lifespan and avoid potential issues.

Regular maintenance tasks to keep the Txv in good condition

To keep the Txv working efficiently, it is essential to perform routine maintenance tasks. Here are some important tips to consider:

- Inspect the Txv for any visible signs of damage or wear regularly.

- Check all the electrical connections and wiring for loose connections or corrosion.

- Ensure that there are no obstructions around the Txv that could restrict airflow.

- Inspect the refrigerant levels and top up if necessary.

- Check the filter for any build-up or clogs and clean or replace it as needed.

- Make sure that the condenser and evaporator coils are clean and free from debris.

How to clean and inspect the Txv periodically

Cleaning and inspecting the Txv periodically are essential to prevent any potential issues that may arise due to dirt or debris accumulation. Follow these steps to clean and inspect the Txv:

- Start by turning off the power supply to the Txv.

- Remove any outer covers or panels to access the Txv.

- Using a soft brush or cloth, gently clean away any dust or dirt from the Txv components.

- Inspect the Txv for any signs of wear, rust, or damage. If any issues are found, it is recommended to seek professional assistance for repair or replacement.

- Check the tubing and fittings for any leaks and ensure they are properly sealed.

- Once the cleaning and inspection are complete, reassemble the Txv and restore the power supply.

Importance of professional servicing and when to seek assistance

While regular maintenance tasks and periodic cleaning are important, engaging a professional for servicing the Txv is crucial for its long-term functionality. Professional service technicians have the expertise and tools required to identify potential problems and address them effectively to ensure the Txv operates at its best. It is recommended to seek professional assistance in the following situations:

- If the Txv is not responding properly to temperature adjustments.

- If there are unusual noises or vibrations coming from the Txv.

- If there is a considerable decrease in cooling or heating efficiency.

- If there is a refrigerant leak or any other visible issues with the Txv.

Remember, regular maintenance, periodic cleaning and inspection, and professional servicing are vital for maintaining and extending the lifespan of your Txv system. By following these guidelines and seeking assistance when needed, you can enjoy reliable and efficient performance from your Txv for years to come.

Safety Precautions And Best Practices

When it comes to installing a TXV (Thermostatic Expansion Valve), it’s crucial to prioritize safety precautions and adhere to best practices. Taking the necessary steps to protect yourself and your surroundings is essential for a successful and accident-free installation. In this section, we will discuss the important safety measures to follow, proper handling and disposal of refrigerants, as well as tips for avoiding common mistakes and errors during the installation process.

Safety measures to follow during TXV installation

During the installation of a TXV, it’s important to prioritize safety to prevent accidents and ensure a smooth process. Here are some safety measures you should follow:

- Ensure the power supply is turned off before starting the installation.

- Wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and a face mask.

- Use caution when working with electrical components and be aware of potential shocks.

- Keep the work area clean and free from any obstructions.

- Always follow the manufacturer’s instructions and guidelines for proper installation.

- Double-check all connections and tighten them securely.

- Test the system after installation to ensure it is functioning correctly.

Proper handling and disposal of refrigerants

Handling and disposing of refrigerants correctly is crucial for both the environment and your safety. Here are some best practices to follow:

- Use approved containers to store and transport refrigerants.

- Ensure proper labeling of refrigerant containers to avoid confusion.

- Handle refrigerants in well-ventilated areas to prevent inhaling harmful fumes.

- Follow local regulations and guidelines for the disposal of refrigerants.

- Avoid releasing refrigerants into the atmosphere.

- Consider recycling or reclaiming refrigerants whenever possible.

Tips for avoiding common mistakes and errors during installation

To ensure a successful TXV installation, it’s important to be aware of common mistakes that can occur. Here are some tips to help you avoid these errors:

- Read and understand the installation instructions thoroughly before starting the process.

- Take care not to overtighten fittings, as it can cause damage or leaks.

- Use the correct tools and equipment for the installation.

- Check for any refrigerant leaks using a leak detector or soapy water solution.

- Follow the correct torque specifications for tightening valve components.

- Ensure proper insulation of refrigerant lines to prevent condensation.

By following these safety precautions and best practices, you can ensure a smooth, accident-free TXV installation. Remember to always prioritize safety and take the necessary steps to protect yourself, others, and the environment throughout the process.

Frequently Asked Questions Of How To Install A Txv

How Should A Txv Be Mounted?

The TXV should be mounted following these guidelines: 1) Position it in the liquid line close to the evaporator coil. 2) Ensure it is mounted vertically, with the bulb and sensing element secured to the suction line near the outlet.

3) Use a thermally conductive compound between the bulb and the suction line. 4) Insulate the bulb and sensing element to prevent ambient temperature interference. 5) Connect the TXV to the suction and liquid lines firmly.

How Long Does It Take To Install A Txv?

Installing a TXV typically takes around 1-2 hours. The process involves removing the old valve, ensuring proper fitment and alignment of the new TXV, and reconnecting the necessary components. A qualified technician should be able to complete the installation within this timeframe.

Does It Matter If The Txv Is Upside Down?

The orientation of the TXV does matter. It needs to be installed in the correct position for proper functioning.

How Are Thermal Expansion Valves Installed?

To install thermal expansion valves, follow these steps: 1. Identify the correct location on the refrigerant line. 2. Cut the pipe and clean the ends with a suitable pipe cutter and deburring tool. 3. Insert the expansion valve in the correct orientation and ensure tight fitting.

4. Tighten the compression nut to secure the valve. 5. Test for leaks and ensure proper functioning of the valve.

Conclusion

Installing a TXV can be a simple and effective way to improve the functioning of your HVAC system. By following the steps outlined in this guide, you can successfully install a TXV and enhance the efficiency and performance of your system.

Take the time to understand the process, gather the necessary tools, and follow the instructions carefully. With the right knowledge and attention to detail, you can ensure a successful installation that will benefit your HVAC system for years to come.