To install a TPS sensor, first, locate the sensor on the throttle body. Then, disconnect the sensor’s electrical connector and remove the mounting screws.

Understanding The Tps Sensor

When it comes to modern automobiles, there are various sensors that play a crucial role in ensuring impeccable performance. One such important sensor is the Throttle Position Sensor (TPS). Whether you are a car enthusiast or a professional mechanic, having a good understanding of the TPS sensor is essential. In this article, we will delve into the various aspects of the TPS sensor, including what it is, its functions, and the importance of proper installation.

What is a TPS Sensor?

The Throttle Position Sensor (TPS) is a vital component of the engine control system. It is responsible for monitoring the position of the throttle plate or butterfly valve in the throttle body. The TPS works by sending signals to the engine control unit (ECU) to determine the amount of air entering the engine. It acts as a bridge between the driver’s command via the accelerator pedal and the engine’s fuel injection system.

Functions of TPS Sensor

The TPS sensor performs several key functions in an automotive engine:

- Throttle Angle Measurement: The TPS sensor measures the angle of the throttle plate, enabling the ECU to accurately determine the throttle position.

- Engine Load Calculation: By indicating the throttle position, the TPS sensor helps calculate the engine load. This information is crucial in determining the correct air-fuel mixture for optimum performance and fuel efficiency.

- Idle Control: The TPS sensor also plays a role in idle control. By monitoring the throttle plate position at idle, the sensor helps regulate the engine’s idle speed.

- Transmission Shifts: In vehicles with automatic transmissions, the TPS sensor assists in smooth and timely shifting by providing information about throttle position and changes in load.

Importance of Proper TPS Sensor Installation

Proper TPS sensor installation is essential for ensuring optimal engine performance. Here’s why it matters:

- Accurate Throttle Response: A well-installed TPS sensor ensures accurate and instantaneous throttle response, allowing for precise control over the engine’s power output.

- Fuel Efficiency: Correct TPS sensor installation helps maintain the ideal air-fuel ratio, enhancing fuel efficiency and reducing emissions.

- Prevention of Engine Issues: Improper TPS sensor installation can lead to erratic throttle response, loss of power, and even engine stalling. By installing the sensor correctly, these issues can be prevented.

In conclusion, the TPS sensor is a critical component of an automobile’s engine control system. By understanding what it is, its functions, and the importance of proper installation, you can ensure optimum engine performance and longevity. When installing a TPS sensor, it is advisable to follow the manufacturer’s instructions and utilize the appropriate tools to achieve accurate and reliable results.

Preparing For Installation

Before you start installing a TPS sensor, it’s important to make sure you have everything you need and take the necessary safety precautions. This will ensure a smooth and successful installation process. In this section, we will go over the tools and materials you will need as well as the safety precautions you should keep in mind.

Tools and Materials Required

When it comes to installing a TPS sensor, having the right tools and materials is crucial. Here’s a list of everything you will need:

| Tools | Materials |

|---|---|

| Socket wrenchSocket setAdjustable wrenchHex key setFlathead screwdriver | New TPS sensorSocket wrenchSocket setAdjustable wrenchHex key setFlathead screwdriver |

Having these tools and materials readily available will save you time and ensure a hassle-free installation.

Safety Precautions

Before you begin working on your vehicle, it’s important to prioritize your safety. Here are some safety precautions to keep in mind:

- Make sure your vehicle is parked on a flat and level surface.

- Engage the parking brake to prevent the vehicle from moving.

- Wear safety goggles to protect your eyes from any debris.

- Disconnect the vehicle’s battery to avoid any electrical mishaps.

- Allow the engine to cool down before starting the installation process.

By following these safety precautions, you can minimize the risk of accidents or injuries while working on your vehicle.

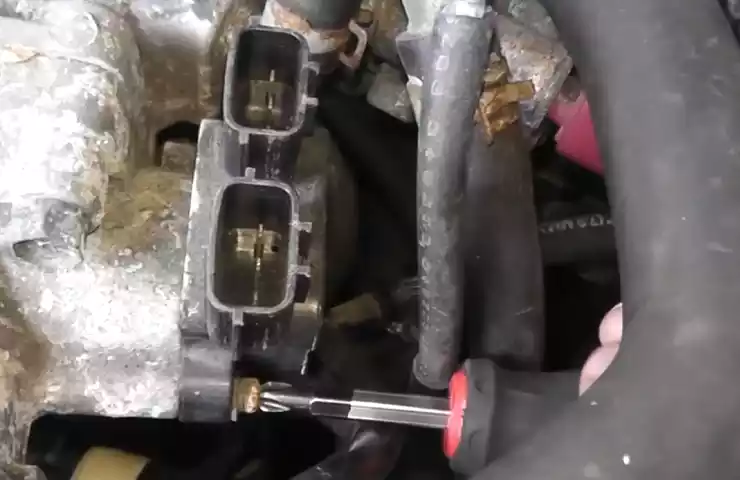

Step-By-Step Installation Process

<h2>Step-by-Step Installation Process</h2> <h3>Step 1: Disconnecting the Battery</h3> Before starting the installation process, it’s crucial to disconnect the battery to ensure your safety. To do this, locate the battery in your vehicle and remove the negative terminal with a wrench. This step will help prevent any accidental electrical shocks or damage to the sensor during the installation process. <h3>Step 2: Locating the TPS Sensor</h3> The Throttle Position Sensor (TPS) can be found on the throttle body, which is connected to the intake manifold. To locate it, consult your vehicle’s manual or do a quick online search to find a diagram specific to your make and model. Identifying the TPS sensor’s location is essential before proceeding with the installation. <h3>Step 3: Removing the Old TPS Sensor</h3> With the TPS sensor location identified, you can now remove the old sensor. Start by carefully unplugging the electrical connector attached to the TPS sensor. Next, take a screwdriver or socket wrench and remove the screws or bolts securing the sensor onto the throttle body. Once removed, set the old TPS sensor aside. <h3>Step 4: Cleaning the Mounting Surface</h3> Before installing the new TPS sensor, it’s crucial to clean the mounting surface to ensure a proper and secure fit. Use a clean cloth and a mild degreaser to wipe away any dirt, debris, or residue from the throttle body’s surface. This step will help remove any contaminants that could potentially interfere with the sensor’s performance. <h3>Step 5: Installing the New TPS Sensor</h3> Now it’s time to install the new TPS sensor. Take the new sensor and align it with the bolt holes on the throttle body. Once aligned, insert and hand-tighten the screws or bolts to secure the sensor in place. Remember not to overtighten, as it may cause damage to the sensor. <h3>Step 6: Adjusting the TPS Sensor Position</h3> Properly adjusting the TPS sensor is crucial for optimal performance. To do this, carefully rotate the sensor until it aligns with the correct position. Many sensors have specific alignment marks, so make sure to line them up accurately. Take your time with this step to ensure the sensor is in the correct position for accurate readings. <h3>Step 7: Securing the TPS Sensor</h3> To ensure the TPS sensor stays securely in place, use a screwdriver or socket wrench to tighten the screws or bolts that hold it onto the throttle body. As mentioned earlier, remember not to overtighten to prevent any damage. <h3>Step 8: Reconnecting the Battery</h3> With the TPS sensor securely installed, it’s time to reconnect the battery. Start by reattaching the negative terminal and tightening it with a wrench. This step will restore power to your vehicle and allow the new TPS sensor to function correctly. In conclusion, replacing a TPS sensor can be a relatively straightforward process when following the step-by-step installation process. By disconnecting the battery, locating the TPS sensor, removing the old sensor, cleaning the mounting surface, installing the new sensor, adjusting its position, securing it in place, and reconnecting the battery, you can successfully replace your TPS sensor and ensure optimal performance of your vehicle’s throttle system. Remember to consult your vehicle’s manual or seek professional advice if you encounter any difficulties or uncertainties during the installation process.

Testing And Calibration

Proper testing and calibration of a Throttle Position Sensor (TPS) is crucial for ensuring smooth throttle operation and optimal vehicle performance. In this section, we will discuss the importance of testing the TPS, as well as the step-by-step process for checking throttle operation, performing voltage testing using a multimeter, and calibrating the TPS sensor.

Importance of Testing

Testing the TPS is essential because it allows you to identify any potential issues that may affect the throttle operation. A malfunctioning TPS can cause irregular throttle response, engine hesitation, or even stalling. By conducting thorough testing, you can diagnose the problem accurately and take the necessary steps to resolve it.

Step 1: Checking for Smooth Throttle Operation

The first step in the testing process is to check for smooth throttle operation. Start by removing the air intake hose to gain access to the throttle body. With the engine off and the ignition key in the “ON” position, manually open and close the throttle plate to ensure it moves smoothly without any sticking or binding. If you notice any resistance or rough movement, it may indicate a problem with the throttle body or the TPS itself.

Step 2: Using a Multimeter for Voltage Testing

Next, you’ll need to use a multimeter to perform voltage testing on the TPS. Start by disconnecting the electrical connector from the TPS and set your multimeter to the DC voltage setting. Connect the positive lead of the multimeter to the signal wire terminal on the TPS connector and the negative lead to a good ground. With the ignition key in the “ON” position, slowly open the throttle while monitoring the voltage reading on the multimeter. The voltage should increase smoothly and without any sudden jumps or drops. If you observe any erratic readings, it may indicate a faulty TPS that needs to be replaced.

Step 3: Calibrating the TPS Sensor

Calibrating the TPS sensor is the final step in the testing and installation process. Each vehicle manufacturer may have specific calibration procedures, so it’s essential to refer to the vehicle’s service manual for precise instructions. However, in general, the calibration process involves carefully adjusting the TPS sensor to ensure it provides the correct voltage output at various throttle positions. This can usually be done by loosening the TPS mounting screws and rotating the sensor accordingly. Once calibrated, make sure to verify the voltage readings using the multimeter to ensure accurate TPS functionality.

By following these steps and performing thorough testing and calibration, you can successfully install and ensure optimal performance from a TPS sensor in your vehicle.

Troubleshooting Common Issues

After installing a TPS sensor, it’s important to ensure it is properly functioning to avoid any potential issues with your vehicle’s throttle response, engine stalling, and idle surging. In this section, we’ll go over common symptoms that may arise after installing a TPS sensor, possible causes, and the steps you can take to troubleshoot and resolve these issues.

Symptom 1: Erratic Throttle Response

One common issue that you may encounter after installing a TPS sensor is erratic throttle response. This can manifest as jerky acceleration, delayed response when pressing the gas pedal, or sudden surges in engine power. It can be frustrating and potentially dangerous if left unresolved.

Symptom 2: Engine Stalling

Another symptom that indicates a problem with the TPS sensor is engine stalling. If your vehicle’s engine frequently shuts off or loses power unexpectedly, it could be due to an issue with the TPS sensor. Engine stalling can occur when the sensor is not providing accurate throttle position data to the engine control unit (ECU).

Symptom 3: Idle Surging

Idle surging is another common issue associated with a faulty TPS sensor. When the sensor is malfunctioning, it may send incorrect signals to the ECU, causing the engine to fluctuate in RPM while idling. This can result in rough idling, where the engine speed alternates between high and low, making the vehicle feel unstable at rest.

Possible Causes

Now that we’ve discussed the symptoms, let’s explore some possible causes of these issues. The erratic throttle response, engine stalling, and idle surging can be attributed to the following:

- TPS sensor misalignment or improper installation

- Wiring issues, such as loose connections or damaged wires

- Corrosion or dirt buildup on the sensor contacts

- Malfunctioning ECU

Troubleshooting Steps

To diagnose and fix the issues with your TPS sensor, follow these troubleshooting steps:

- Inspect the TPS sensor for any visible signs of damage or misalignment. Ensure it is securely attached and properly aligned with the throttle shaft.

- Check the wiring connections associated with the TPS sensor. Look for any loose or damaged wires and repair or replace them as necessary.

- Clean the sensor contacts using an electrical contact cleaner to remove any dirt or corrosion that may be affecting its performance.

- If the above steps don’t resolve the issues, it might be necessary to replace the TPS sensor altogether. Consult your vehicle’s service manual or seek professional assistance for guidance on selecting and installing a new sensor.

- If problems persist after replacing the TPS sensor, it could be indicative of a faulty ECU. In this case, it is recommended to have your vehicle inspected by a qualified technician for further diagnosis and repair.

By following these troubleshooting steps, you can effectively identify and address common issues that may occur after installing a TPS sensor. Ensuring the proper functioning of your TPS sensor is crucial for optimal throttle response and overall engine performance.

Additional Tips And Recommendations

Installing a TPS sensor is crucial for the overall performance of your vehicle. However, it’s not enough to simply install the sensor. Regular maintenance, seeking professional help when needed, and following best practices for TPS sensor installation are equally important. In this section, we will discuss some additional tips and recommendations that will help ensure a smooth installation and optimum performance of your TPS sensor.

Regular Maintenance

Maintaining your TPS sensor on a regular basis is key to its longevity and accurate functioning. Here are a few maintenance tips to keep in mind:

- Inspect the sensor’s wiring harness regularly for any signs of damage or wear. Replace it if necessary.

- Ensure the sensor is securely mounted in place and free from any debris or dirt that could interfere with its readings.

- Regularly clean the throttle body to prevent any dirt or carbon buildup that could affect the sensor’s performance.

- Check for any trouble codes related to the TPS sensor using a diagnostic tool, and address them promptly.

Seeking Professional Help

While installing a TPS sensor can be done by yourself, it’s always a good idea to seek professional help if you’re unsure or unfamiliar with the process. A qualified mechanic or technician can ensure the sensor is installed correctly and perform any necessary calibrations to guarantee accuracy.

Best Practices for TPS Sensor Installation

Follow these best practices to ensure a successful TPS sensor installation:

- Refer to the manufacturer’s instructions and specifications for your specific vehicle make and model.

- Disconnect the negative battery cable before starting the installation.

- Use appropriate tools and equipment for the installation.

- Double-check the sensor’s alignment and make sure it is aligned properly with the throttle shaft.

- Torque the bolts or screws to the manufacturer’s recommended specifications.

- Perform a thorough test and calibration after installation to verify the sensor’s accuracy.

By following these additional tips and recommendations, you can ensure a smooth and hassle-free installation of your TPS sensor. Remember, regular maintenance and seeking professional help when needed are crucial for optimum performance and longevity.

Frequently Asked Questions On How To Install A Tps Sensor

Do You Have To Calibrate A New Tps Sensor?

No, you don’t need to calibrate a new TPS sensor. It comes pre-calibrated and ready to use. Just install it properly and it should function correctly without any further adjustments.

Can You Replace A Throttle Position Sensor Yourself?

Yes, you can replace a throttle position sensor yourself. It’s a simple process that you can do at home.

Does A Throttle Position Sensor Need To Be Programmed?

No, a throttle position sensor does not typically need to be programmed. It is a plug-and-play component that relays information about the position of the throttle to the engine control unit.

What Are The 3 Wires On A Tps Sensor?

The TPS sensor has 3 wires that serve different purposes. One wire receives a reference voltage from the PCM, another wire sends a signal voltage back to the PCM indicating the throttle position, and the third wire is a ground wire for electrical circuit completion.

Conclusion

Installing a TPS sensor is a crucial step in ensuring the smooth functioning of your vehicle’s engine. By following the step-by-step process outlined in this guide, you can easily install a TPS sensor without any hassle. Remember to exercise caution and refer to your vehicle’s manual for specific instructions.

With a properly installed TPS sensor, you can improve the overall performance and fuel efficiency of your vehicle. So, get started with the installation process today and enjoy a better driving experience!