To install a mass air flow sensor, disconnect the negative terminal of the battery and remove the air intake hose and any electrical connections. Are you looking to install a mass air flow sensor in your vehicle?

Whether you’re experiencing performance issues or simply want to improve your engine’s efficiency, installing a mass air flow sensor can help. This device measures the amount of air entering the engine and provides valuable data to the engine control unit.

In this guide, we’ll walk you through the steps to install a mass air flow sensor in your vehicle. By following these instructions, you’ll be able to complete the installation with ease and get your vehicle back on the road in no time. Let’s get started.

Understanding The Mass Air Flow Sensor

The mass air flow sensor is a crucial component in your vehicle’s engine management system. It measures the amount of air entering the engine to determine the correct air-fuel mixture required for combustion. Understanding how this sensor works and its importance in maintaining proper engine performance is essential for any car enthusiast or DIY mechanic.

What is a Mass Air Flow Sensor?

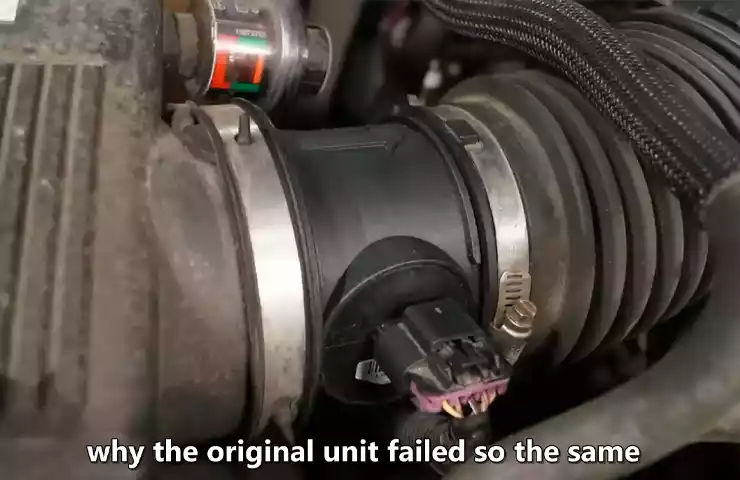

A mass air flow sensor, often referred to as MAF sensor, is a device that measures the speed and volume of air entering the engine. It is typically located near the intake manifold or air filter housing. The sensor consists of a thin wire, known as a hot wire or film, that is exposed to the incoming air. As the air passes over the wire, it cools it down, and the sensor measures the change in temperature to determine the airflow.

Functions of the Mass Air Flow Sensor

The mass air flow sensor serves multiple functions in your vehicle’s engine system:

- Determining the proper air-fuel mixture: The sensor’s measurements enable the engine control unit (ECU) to calculate the correct amount of fuel needed for combustion. By adjusting the fuel injector pulse width based on the airflow, the sensor ensures an optimal air-fuel mixture for efficient combustion.

- Controlling engine performance: The MAF sensor helps the ECU monitor and control various engine parameters, such as ignition timing and throttle response. Accurate airflow measurements allow the ECU to make real-time adjustments and optimize engine performance.

- Ensuring compliance with emissions regulations: The MAF sensor plays a crucial role in controlling emissions by providing data on the amount of air entering the engine. This information allows the ECU to adjust the fuel injection and emission control systems to meet regulatory standards.

Importance of a properly functioning Mass Air Flow Sensor

A properly functioning mass air flow sensor is vital for your vehicle’s overall performance and fuel efficiency. Here’s why:

- Improved engine performance: When the MAF sensor is operating correctly, it ensures that the engine receives the precise amount of air needed for efficient combustion. This results in smoother acceleration, increased power, and better overall performance.

- Enhanced fuel efficiency: Accurate airflow measurements allow the ECU to deliver the right amount of fuel, minimizing fuel wastage and maximizing fuel economy. A faulty MAF sensor can lead to improper fuel calculations, causing poor mileage and increased fuel consumption.

- Reduced emissions: A properly functioning MAF sensor helps maintain optimal air-fuel ratios, leading to cleaner and more efficient combustion. This, in turn, reduces harmful emissions, contributing to a greener environment and ensuring compliance with emissions regulations.

Given the vital role of the mass air flow sensor in your vehicle’s engine management system, it is important to ensure it is functioning correctly. Regular maintenance, including cleaning and proper installation, can help prolong the sensor’s lifespan and ensure optimal engine performance.

Tools And Materials Needed

Before you can install a mass air flow sensor, you’ll need to gather the necessary tools and materials. Having everything prepared will ensure a smooth and efficient installation process. Here’s a breakdown of what you’ll need:

List of tools required for installation

- Socket wrench set – To remove and install bolts

- Screwdriver set – For removing and tightening screws

- Pliers – To grip and manipulate small parts

- Wire cutters/strippers – For cutting and stripping wires

- Torque wrench – To apply the correct amount of torque to bolts

- Multi-meter – To test electrical connections

- Light source – To illuminate tight spaces

Necessary materials for the installation process

- New mass air flow sensor – Ensure compatibility with your vehicle’s make and model

- Cleaning solvent – For cleaning the sensor housing, if necessary

- Electrical tape – For securing wire connections

- Zip ties – To neatly organize and secure wires

- Dielectric grease – To protect electrical connections from moisture

- Throttle body cleaner – To clean the throttle body

- Shop towels – For general cleaning and wiping surfaces

- Latex gloves – To protect your hands from dirt and contaminants

Having all the tools and materials on hand will streamline the installation process and help you avoid any unnecessary delays. Now that you’re fully prepared, let’s move on to the step-by-step instructions on how to install a mass air flow sensor.

Step-By-Step Guide To Installing A Mass Air Flow Sensor

Step-by-Step Guide to Installing a Mass Air Flow Sensor

If you’re experiencing issues with your vehicle’s engine performance or fuel efficiency, a faulty mass air flow (MAF) sensor might be the culprit. The MAF sensor plays a crucial role in regulating the amount of air entering the engine, ensuring optimal combustion and overall efficiency. In this step-by-step guide, we will walk you through the process of installing a new MAF sensor, helping you restore your vehicle’s performance and efficiency. Let’s get started!

Preparing the vehicle for installation

Before you begin the installation process, make sure you have the necessary tools and equipment readily available. Additionally, ensure that the engine is turned off and has completely cooled down before proceeding. Here is a list of tools and equipment you will need:

- Socket set

- Screwdriver

- MAF sensor cleaner (if necessary)

- New MAF sensor

Once you have gathered all the required tools, follow these steps to prepare the vehicle for installation:

- Locate the MAF sensor housing, usually positioned between the air filter box and the throttle body.

- Disconnect the negative terminal of the vehicle’s battery to avoid any electrical issues during the installation process.

Removing the old Mass Air Flow Sensor

The next step is to remove the old MAF sensor carefully. Follow these simple steps to ensure a hassle-free removal process:

- Identify the electrical connector attached to the MAF sensor and gently disconnect it by pressing the release tab.

- Use an appropriate socket or screwdriver to remove any bolts or clamps securing the MAF sensor in place.

- Once all fasteners are removed, carefully slide out the old MAF sensor from its housing.

- Inspect the sensor and its housing for any signs of damage or debris. If necessary, clean the housing using MAF sensor cleaner before proceeding.

Installing the new Mass Air Flow Sensor

Now that the old sensor is removed, it’s time to install the new MAF sensor. Follow these steps to ensure a proper installation:

- Take the new MAF sensor out of its packaging and ensure that it matches the specifications of the original sensor.

- Carefully insert the new MAF sensor into the housing, aligning it properly with any corresponding guides or pins.

- Tighten the bolts or clamps to secure the MAF sensor in place, ensuring a snug fit without over-tightening.

Connecting the wiring and securing the sensor in place

After installing the new sensor, it’s important to reconnect the electrical wiring and secure the sensor in its housing. Follow these steps:

- Attach the electrical connector to the new MAF sensor, ensuring a secure and proper connection.

- Double-check that all bolts or clamps securing the sensor are tight but not over-tightened, as this can cause damage.

Testing the new Mass Air Flow Sensor

Now that the installation is complete, it’s essential to test the new MAF sensor to ensure proper functionality. Follow these steps:

- Reconnect the negative terminal of the vehicle’s battery.

- Start the engine and allow it to idle for a few minutes to ensure proper initialization of the new MAF sensor.

- Observe the engine’s performance and keep an eye out for any warning lights on the dashboard.

- If everything appears to be functioning correctly, take the vehicle for a test drive to ensure smooth acceleration and optimal fuel efficiency.

Congratulations! You have successfully installed a new mass air flow sensor in your vehicle, helping to maintain its performance and fuel efficiency. Remember to refer to your vehicle’s specific service manual for any additional instructions or precautions. Enjoy the improved driving experience!

Preparing The Vehicle For Installation

To install a mass air flow sensor, it is important to properly prepare your vehicle. This involves parking the vehicle on a level surface, disconnecting the negative battery terminal, and locating the mass air flow sensor. By following these steps, you can ensure a smooth and successful installation process.

Park the Vehicle on a Level Surface

When beginning the installation process, it is crucial to park your vehicle on a level surface. This provides a stable foundation and prevents any unintended movement while working on your vehicle. It is also important to engage the parking brake to further secure the vehicle in place.

Disconnecting the Negative Battery Terminal

Prior to starting any work on your vehicle, it is essential to disconnect the negative terminal of the battery. This is a necessary safety measure to avoid any electrical mishaps or injuries during the installation process. To disconnect the negative terminal, use a wrench to loosen the nut and carefully remove the cable from the battery post.

Locating the Mass Air Flow Sensor

Next, you need to locate the mass air flow sensor in your vehicle. The mass air flow sensor is generally located between the air filter housing and the engine intake manifold. Refer to your vehicle’s owner’s manual or consult online resources for specific information on the location of the sensor in your particular make and model.

Once you have located the mass air flow sensor, visually inspect the area around it to familiarize yourself with its position. This will help you when it comes time to remove and replace the sensor during the installation process.

Removing The Old Mass Air Flow Sensor

If you suspect that your car’s mass air flow sensor is faulty or you simply need to replace it, the first step is to remove the old sensor. This process requires a few simple tools and can be accomplished in just a few minutes. Follow the steps below to remove the old mass air flow sensor from your vehicle.

Removing any obstruction or housing covers

The mass air flow sensor is typically located between the air filter box and the engine intake. Before you can access the sensor, check for any obstructions or housing covers that may be in the way. If you see any, remove them carefully to gain full access to the sensor. Make sure to keep track of any screws or clips that you remove, as they will need to be reinstalled later.

Disconnecting the electrical connectors

Once you have a clear path to the mass air flow sensor, you’ll need to disconnect the electrical connectors. These connectors supply power and data to the sensor. Carefully examine the connectors and locate any locking mechanisms. Gently release the locks, if present, and then proceed to unplug the connectors. Take note of the position of each connector, as you’ll need to reinstall them in the correct orientation later.

Loosening the clamps or screws securing the sensor

With the electrical connectors disconnected, the next step is to loosen the clamps or screws that secure the mass air flow sensor in place. Depending on your vehicle, you may encounter either clamps or screws. Determine which type holds the sensor in place and use the appropriate tool to loosen them. Be careful not to damage any surrounding components as you perform this step.

Table: Tools Required for Removing the Old Mass Air Flow Sensor

| Tool | Function |

|---|---|

| Screwdriver | For removing screws or clips |

| Pliers | For loosening clamps |

Once you have successfully loosened the clamps or screws, carefully lift the old mass air flow sensor out of its housing. Take note of its orientation, as the new sensor should be installed in the same position. Inspect the sensor and the housing for any signs of damage or contamination. If everything looks good, proceed to the installation of the new mass air flow sensor.

By following these steps, you should now have successfully removed the old mass air flow sensor from your vehicle. Take your time and be gentle while disassembling to avoid any damage. In the next section, we will guide you through the process of installing the new mass air flow sensor.

Installing The New Mass Air Flow Sensor

Once you have removed the old mass air flow sensor from your vehicle, it’s time to install the new one. This step-by-step guide will walk you through the process, ensuring that the replacement is completed correctly.

Placing the new sensor in position

Firstly, carefully place the new mass air flow sensor in position. Ensure that it is aligned correctly with the air intake duct and that any necessary gaskets or seals are in place. Placing the sensor in the wrong position could result in inaccurate readings and potential engine issues down the line.

Aligning and tightening the clamps or screws

With the new mass air flow sensor in position, you’ll need to secure it tightly to prevent any air leaks. If your sensor has clamps, position them over the connection points and align them accordingly. Use a screwdriver or wrench to tighten the clamps securely. Alternatively, if your sensor uses screws for attachment, align the sensor with its mounting holes and carefully insert and tighten the screws using the appropriate tool.

Reconnecting the electrical connectors

Once the new mass air flow sensor is properly secured, it’s time to reconnect the electrical connectors. These connectors provide power and enable communication between the sensor and your vehicle’s engine control unit. Locate the corresponding connectors and carefully plug them in. Ensure that they are firmly connected and that there are no loose or damaged wires.

Take a moment to double-check all the connections you have made:

- Verify that the new mass air flow sensor is securely in place and aligned correctly.

- Confirm that the clamps or screws holding the sensor are tight.

- Ensure that the electrical connectors are firmly plugged in and that there are no visible issues with the wiring.

By following these steps, you have successfully installed the new mass air flow sensor in your vehicle. This critical component plays a vital role in the proper functioning of the engine, so it’s important to perform the installation correctly.

Now that you have completed the installation process, you can rest assured that your vehicle’s air intake system will be operating optimally and providing accurate readings to the engine control unit.

Connecting The Wiring And Securing The Sensor In Place

Once you have successfully removed the old mass air flow sensor, it’s time to connect the wiring harness to the new sensor and secure it in place. This critical step ensures that the sensor can function properly and provide accurate readings to your vehicle’s engine control unit. Follow these steps to complete the installation:

1. Connecting the wiring harness to the new sensor

Begin by locating the wiring harness connected to your vehicle’s engine. This harness contains several electrical connectors, one of which is designed to connect to the mass air flow sensor. Take your new sensor and find the corresponding connector on its body.

Line up the connectors carefully, ensuring they are aligned correctly. Push the two connectors together until you hear a firm click or feel them lock securely. This indicates that the electrical connection has been successfully established.

2. Ensuring that all connections are secure and properly aligned

After connecting the wiring harness, double-check all connections to ensure they are secure and properly aligned. Inspect the connectors for any visible signs of damage or loose wires. If you notice any issues, take the necessary steps to address them before proceeding with the installation.

Additionally, make sure there are no obstructions or debris in the area surrounding the sensor. Clean any dirt or debris that may have accumulated, as this can affect the sensor’s performance over time.

3. Reinstalling any housing covers or obstructions

With the wiring connections secure, proceed to reinstall any housing covers or obstructions that were removed during the initial removal process. Ensure that each cover is properly aligned and seated in its original position.

Depending on your vehicle’s make and model, you may need to use specific tools or fasteners to secure the covers in place. Refer to your vehicle’s service manual or consult a professional if you are uncertain about the proper installation methods.

Always take care not to overtighten any screws or fasteners, as this can damage the housing covers or cause them to crack.

Connecting the wiring and securing the mass air flow sensor in place is a critical step in the installation process. By properly aligning the connectors, ensuring all connections are secure, and reinstalling any housing covers, you can ensure that your vehicle’s new sensor functions optimally and provides accurate readings to the engine control unit.

Remember to follow the manufacturer’s instructions and any specific guidelines provided by your vehicle’s manufacturer. Proper installation of the mass air flow sensor will help maintain the performance and efficiency of your vehicle’s engine.

Testing The New Mass Air Flow Sensor

Reconnecting the Negative Battery Terminal

Once the new mass air flow sensor is properly installed, it’s important to reconnect the negative battery terminal. This step ensures that the vehicle’s electronic control unit (ECU) resets and recognizes the new sensor. To reconnect the negative battery terminal, follow these simple steps:

- Locate the negative (-) terminal on the vehicle’s battery.

- Using a wrench or a socket, carefully loosen and remove the bolt securing the negative battery cable.

- Slide the cable off the battery terminal and set it aside.

- Wait for approximately 10 minutes to allow the ECU to fully reset.

- Reattach the negative battery cable to the battery terminal and tighten the bolt securely.

By reconnecting the negative battery terminal, you ensure that the ECU recognizes the new mass air flow sensor, allowing it to operate optimally.

Starting the Vehicle and Observing for Any Issues

Once the negative battery terminal is reconnected, it’s time to start the vehicle and observe for any issues. Follow these steps to start the vehicle:

- Get inside the vehicle and ensure that it is in park or neutral.

- Insert the key into the ignition and turn it to the “on” position without starting the engine.

- Allow the vehicle’s fuel pump to prime itself by waiting for a few seconds.

- Once the fuel pump has primed, start the engine and let it run for a few minutes.

- Observe the vehicle closely for any warning lights, unusual noises, or erratic engine behavior.

While observing the vehicle, pay close attention to any potential issues that may arise. If you notice any abnormalities, such as a rough idle, hesitation, or warning lights, it may indicate a problem with the new mass air flow sensor installation.

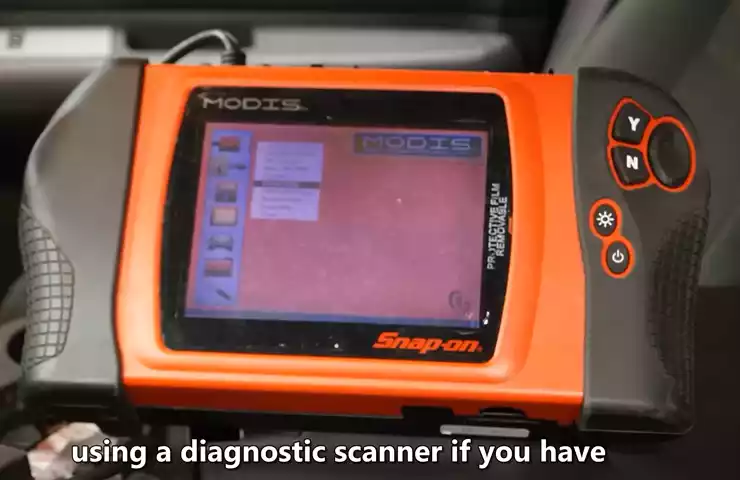

Checking for Proper Sensor Functionality by Scanning for Error Codes

One of the most effective ways to determine if the new mass air flow sensor is functioning correctly is to scan for error codes using a diagnostic tool. Here’s how to do it:

- Connect the diagnostic tool to the vehicle’s OBD-II port, usually located under the dashboard on the driver’s side.

- Turn the ignition key to the “on” position without starting the engine.

- Follow the instructions provided with the diagnostic tool to navigate to the error code scanning function.

- Initiate the scanning process and wait for the tool to retrieve any error codes stored in the ECU.

- Review the retrieved error codes, paying particular attention to any codes related to the mass air flow sensor.

If the scanning process reveals any error codes specifically related to the mass air flow sensor, it is an indication that further investigation or adjustment may be necessary to ensure proper functionality.

By following these steps, you can effectively test the new mass air flow sensor installation, ensuring that it is working correctly and allowing your vehicle to perform at its best.

Troubleshooting And Tips

In this section, we will discuss common issues encountered during the installation of a mass air flow sensor, as well as provide some tips for a successful installation and sensor performance. Installing a mass air flow sensor may seem daunting at first, but with the right knowledge and guidance, you can ensure a smooth and effective installation that maximizes performance.

Common issues encountered during installation

During the installation of a mass air flow sensor, some common issues may arise. By being aware of these issues, you can quickly troubleshoot and resolve any problems that may occur. Here are a few issues to watch out for:

- Incorrect sensor orientation: One common mistake during installation is positioning the sensor in the wrong orientation. The sensor typically has an arrow or marking indicating the direction of airflow. Make sure to align this arrow with the direction of airflow to ensure accurate readings.

- Loose or damaged connections: Another issue that may occur is loose or damaged connections. Properly securing the electrical connectors and ensuring they are free from any damage or corrosion is crucial for reliable sensor performance.

- Contaminated sensor: A contaminated sensor can lead to inaccurate readings and poor performance. Therefore, it is essential to handle the sensor with care and avoid touching the sensing element. Additionally, make sure the air intake system is free from dirt, debris, and oil that could contaminate the sensor.

Tips for a successful installation and sensor performance

Follow these tips to ensure a successful installation and optimal performance of your mass air flow sensor:

- Refer to the manufacturer’s instructions: Before starting the installation, carefully read and follow the manufacturer’s instructions. Each sensor may have unique installation requirements, so it is important to familiarize yourself with these guidelines.

- Inspect the air intake system: Before installing the new sensor, inspect the air intake system for any obstructions, leaks, or damaged components. Addressing these issues beforehand will help optimize the performance of the sensor.

- Properly clean the sensor housing: If you are reusing the sensor housing, ensure it is thoroughly cleaned and free from any residue or contaminants. Cleaning the housing will help maintain accurate readings and prevent potential sensor damage.

- Double-check connections: Once you have installed the sensor, double-check all electrical connections to ensure they are secure. Loose or disconnected connections can lead to unreliable readings and decreased performance.

- Perform a sensor calibration: After the installation, it is recommended to perform a sensor calibration, if applicable. This calibration ensures that the sensor is accurately calibrated to the vehicle’s engine specifications, resulting in optimal performance.

By addressing common installation issues and following these tips, you can confidently install a mass air flow sensor and enjoy improved performance and efficiency in your vehicle’s engine. Remember to take your time, be meticulous in the installation process, and always refer to the manufacturer’s instructions for specific guidance.

Frequently Asked Questions For How To Install A Mass Air Flow Sensor

Can You Replace Your Own Mass Air Flow Sensor?

Yes, you can replace your own mass air flow sensor. It’s a relatively simple task that can be done with basic tools and some knowledge about your vehicle. However, it’s important to ensure you get the right replacement sensor for your car’s make and model.

What Happens If You Put The Maf Sensor In Wrong?

Incorrectly installing the MAF sensor can cause engine performance issues. The sensor may not accurately measure airflow, leading to rough idling, stalling, or reduced power. It’s crucial to ensure proper installation to avoid these problems.

Is It Better To Clean Or Replace A Mass Air Flow Sensor?

It is better to clean a mass air flow sensor rather than replace it. Cleaning helps to remove any debris or buildup that may be affecting its performance. Regular cleaning can help maintain the sensor’s accuracy and improve engine efficiency.

Where Is The Correct Position Of The Maf Sensor?

The correct position for the MAF sensor varies depending on the make and model of the vehicle. It is typically located between the air filter and the throttle body. Consult the vehicle’s manual or a professional mechanic for the precise location.

Conclusion

Installing a Mass Air Flow Sensor is an essential task that can enhance the performance of your vehicle. By following the step-by-step instructions provided in this guide, you can successfully install a Mass Air Flow Sensor without any hassle. Make sure to gather all the necessary tools and parts beforehand to ensure a smooth installation process.

Remember, proper installation of the Mass Air Flow Sensor can greatly contribute to the overall functionality and efficiency of your vehicle. So, get started and experience improved performance today!