To install a fuel filter, first, locate the old filter, usually near the fuel tank. Next, disconnect the negative terminal from the battery.

Then, loosen the clamps holding the fuel lines and remove the filter. Finally, install the new filter, reconnect the fuel lines, and reattach the battery terminal. Fuel filters play a crucial role in maintaining the performance and longevity of your vehicle’s engine.

They are responsible for filtering out impurities and contaminants present in the fuel, ensuring clean fuel reaches the engine. Over time, fuel filters can become clogged or worn out, causing a decline in engine efficiency. Therefore, it is essential to learn how to install a fuel filter properly. In this guide, we will provide you with step-by-step instructions to help you easily replace your fuel filter and ensure your engine functions optimally. Let’s dive in and learn the process of installing a fuel filter to keep your vehicle running smoothly.

Understanding The Importance Of A Fuel Filter

Why a Fuel Filter is Necessary to Maintain Your Vehicle’s Performance

A fuel filter plays a crucial role in ensuring the smooth functioning of your vehicle’s engine. It is responsible for filtering out impurities and contaminants that can potentially harm your engine and reduce its performance. Understanding the importance of a fuel filter can help you take proactive measures to maintain your vehicle’s optimal performance.

Signs That Indicate a Clogged or Damaged Fuel Filter

A clogged or damaged fuel filter can lead to a wide range of problems, affecting your vehicle’s performance and fuel efficiency. By recognizing these signs, you can address the issue promptly and prevent further damage. Here are some indicators to watch out for:

- Slow Acceleration: One of the primary signs of a clogged fuel filter is sluggish acceleration. If you notice that your vehicle is taking longer than usual to reach higher speeds or struggling to keep up with traffic, it may be due to a clogged fuel filter restricting the flow of clean fuel.

- Engine Misfires: A clogged fuel filter can cause the engine to misfire or hesitate during acceleration. If you experience irregular engine performance, such as stalling or rough idling, it could indicate a compromised fuel filter.

- Decreased Fuel Efficiency: A reduction in your vehicle’s fuel efficiency can be a direct result of a clogged fuel filter. An obstructed filter can disrupt the fuel flow and cause the engine to consume more fuel than necessary, leading to increased fuel consumption and higher costs at the pump.

- Engine Stalling: A severely clogged fuel filter can cause your engine to stall unexpectedly, particularly when you’re driving at higher speeds or under heavy loads. This sudden loss of power can be dangerous, especially in critical driving situations.

- Difficulty Starting the Engine: If your vehicle has difficulty starting or requires multiple attempts to ignite the engine, a clogged fuel filter could be to blame. A filter that is unable to deliver a steady flow of clean fuel can hinder the combustion process, making it harder to start your engine.

Recognizing these signs and promptly addressing any issues with your fuel filter can help maintain your vehicle’s performance and prevent more serious engine problems down the road. Regularly checking and replacing your fuel filter is a simple yet important maintenance task that can go a long way in ensuring the longevity and efficiency of your vehicle.

Types Of Fuel Filters

When it comes to keeping your car’s fuel system running smoothly, one crucial component is the fuel filter. Fuel filters help to prevent impurities and contaminants from entering the engine, ensuring optimal performance and longevity. There are several types of fuel filters available, each serving a specific purpose. Understanding the different types can help you make an informed decision when it comes to choosing the right fuel filter for your vehicle’s needs.

Inline fuel filters

Inline fuel filters are one of the most common types of fuel filters found in vehicles. As the name suggests, these filters are designed to be installed in the fuel line between the fuel tank and the engine. Inline fuel filters typically come in a cylindrical shape and are available in various sizes to fit different fuel line diameters. These filters are easy to install and replace, making them a popular choice among car owners.

In-tank fuel filters

In-tank fuel filters, also known as fuel strainers, are located inside the fuel tank itself. These filters are commonly found in older vehicles and some newer models as well. In-tank filters are typically attached to the fuel pump or the fuel pick-up tube and are designed to filter out any debris or contaminants that may be present in the fuel. While these filters are not as easily accessible as inline filters, they are known for their durability and long lifespan.

Disposable fuel filters

Disposable fuel filters are designed for one-time use and are meant to be replaced periodically. These filters are often made of paper or synthetic materials and can effectively trap and remove small particles from the fuel. Disposable fuel filters are relatively inexpensive and readily available, making them a popular choice among car owners who prefer quick and hassle-free maintenance.

Non-disposable fuel filters

Non-disposable fuel filters, also known as reusable or washable filters, are designed to be cleaned and reused multiple times. These filters typically have a metal or stainless steel housing and a removable filter element that can be cleaned or replaced as needed. Non-disposable fuel filters offer long-term cost savings and are a more environmentally friendly choice compared to disposable filters. However, they may require more effort and time for maintenance.

Choosing the right fuel filter for your vehicle depends on several factors, such as the age and model of your car, your driving habits, and the condition of the fuel system. It is always recommended to consult your vehicle’s owner manual or seek professional advice to ensure proper fit and functionality. Proper installation and regular maintenance of your fuel filter can help prolong the life of your engine and keep your car running smoothly.

Fuel Filter Installation Kit

| When it comes to maintaining your vehicle’s performance and efficiency, regular fuel filter replacement is essential. A fuel filter installation kit provides you with all the necessary tools and materials to complete this task smoothly. Whether you’re a seasoned DIY mechanic or just starting out, having a fuel filter installation kit on hand can make the process quick and hassle-free. |

| Types of Tools Included in a Standard Fuel Filter Installation Kit1. Socket Wrench – A socket wrench with the appropriate socket size is essential for removing the fuel filter housing.2. Fuel Line Disconnect Tool – This tool is used to disconnect the fuel lines from the filter without causing any damage.3. Screwdriver – A flathead or Phillips screwdriver may be required to remove any screws or clips securing the fuel filter.4. Hose Clamps – Hose clamps are used to secure the fuel lines back onto the new filter, ensuring a tight and leak-free connection.5. Safety Glasses – Safety should always be a priority when working with fuel systems. Wearing safety glasses protects your eyes from any potential hazards. |

| Additional Materials Required for the Installation Process1. Replacement Fuel Filter – Ensure you have a compatible replacement fuel filter that meets the specifications of your vehicle.2. New O-Rings or Gaskets – It’s important to replace the old O-rings or gaskets to prevent fuel leaks. Check your vehicle’s manual or consult an expert to determine the correct size.3. Shop Towels – Having shop towels on hand allows you to quickly clean up any fuel spills or dirt during the installation process.4. Anti-Seize Compound – Applying anti-seize compound to the threads of the fuel filter can prevent corrosion and make future removal easier.5. Fuel Line Clips or Retainers – Depending on your vehicle, you may need additional clips or retainers to secure the fuel lines in place. |

Safety Precautions

When installing a fuel filter, it is crucial to follow important safety measures to ensure a smooth and accident-free process. Working with fuel filters can be hazardous, so taking the necessary precautions is essential to maintain personal safety. This section highlights the key safety measures to keep in mind while working with fuel filters.

Important safety measures to follow when working with fuel filters

- Always deactivate the fuel pump and relieve the fuel pressure before starting the installation process. This can be done by removing the fuel pump fuse or relay, then starting the engine and allowing it to run until it shuts off naturally. This ensures that there is no pressurized fuel in the system when you begin working with the fuel filter.

- Work in a well-ventilated area to prevent the build-up of fumes. Fuel vapors can be hazardous, so it is important to have proper ventilation to prevent any potential risks. Avoid working in enclosed spaces and ensure there is adequate airflow throughout the installation process.

- Avoid any sources of ignition. It is crucial to keep away from open flames, sparks, or any other potential sources of ignition while working with fuel filters. Even the smallest spark can lead to a fire or explosion due to the flammable nature of fuel.

- Wear protective gloves to prevent skin contact with fuel or any other potentially harmful substances. Fuel can irritate or cause harm if it comes into contact with the skin. By wearing gloves, you create a barrier between your skin and the fuel, reducing the risk of any adverse effects.

- Use safety glasses or goggles to protect your eyes. During the installation process, there is a possibility of fuel splashing or debris getting into your eyes. Wearing safety glasses or goggles helps protect your eyes from any potential damage and ensures clear vision throughout the installation.

- Keep a fire extinguisher nearby. As a safety precaution, always have a fire extinguisher within reach when working with fuel filters. In the event of a fire or any other emergency, having a fire extinguisher readily available can help contain and extinguish the flames or mitigate potential hazards.

Protective equipment needed during installation

When installing a fuel filter, it is important to have the necessary protective equipment to safeguard yourself against any potential risks. Here are some essential items you will need:

| Protective Equipment | Description |

|---|---|

| Gloves | Protective gloves made of materials resistant to fuel and chemicals. These help prevent skin contact and potential irritation or harm. |

| Safety Glasses or Goggles | Protective eyewear that shields your eyes from fuel splashes and debris. It ensures clear vision and reduces the risk of eye injuries. |

| Fire Extinguisher | A fire extinguisher that is easily accessible in case of a fire or any other emergency. It helps contain and extinguish flames, minimizing potential hazards. |

By adhering to these important safety precautions and using the necessary protective equipment, you can ensure a safe and successful fuel filter installation. Remember, prioritizing safety is crucial when working with fuel filters to avoid any accidents or injuries.

Locate The Fuel Filter

The fuel filter is an essential component of your vehicle’s fuel system. It helps remove any impurities or debris that may be present in the fuel before it reaches the engine. Over time, the fuel filter can become clogged and affect the performance of your vehicle. That’s why it’s important to know how to locate and replace the fuel filter.

How to Find the Fuel Filter in Your Vehicle

Finding the fuel filter in your vehicle may vary depending on the make and model. Generally, the fuel filter is located along the fuel line between the fuel tank and the engine. To find it, you can follow these steps:

- Refer to your vehicle’s owner’s manual to get specific instructions on the location of the fuel filter.

- Park your vehicle on a flat surface and ensure the engine is turned off.

- Locate the fuel tank, which is usually located under the vehicle towards the rear.

- Trace the fuel line from the fuel tank towards the front of the vehicle.

- Look for a cylindrical or rectangular component along the fuel line.

- Check for any labels or markings that indicate it is the fuel filter.

Different Fuel Filter Locations Based on Car Make and Model

The fuel filter location can vary depending on the car make and model. Here are some common locations:

| Car Make | Car Model | Fuel Filter Location |

|---|---|---|

| Ford | Fiesta | Underneath the vehicle, near the fuel tank |

| Toyota | Corolla | In the engine compartment, near the firewall |

| Chevrolet | Malibu | On the driver’s side of the vehicle, underneath the car |

It’s important to note that these are just general locations and may vary for different generations or trims of the same car model. Always consult your vehicle’s owner’s manual or seek professional guidance if you are unsure about the exact location of the fuel filter.

Once you have located the fuel filter, you can proceed with the installation or replacement process. Remember to follow the manufacturer’s instructions and take necessary safety precautions.

By knowing how to locate the fuel filter in your vehicle, you can maintain the efficiency and performance of your fuel system. Regularly inspect and replace the fuel filter as recommended by your vehicle’s manufacturer to ensure smooth and optimal operation.

Depressurize The Fuel System

Why it’s crucial to depressurize the fuel system before installing a new filter

Depressurizing the fuel system is a critical step when it comes to installing a new fuel filter in your vehicle. This step ensures that any built-up pressure is released, preventing a surge of fuel when you remove the old filter. Failing to depressurize the fuel system can result in fuel spraying out, potentially causing injury and creating a fire hazard. Additionally, depressurizing the system allows for a safer and smoother installation process by minimizing the risk of fuel leaks or other complications.

Step-by-step instructions for depressurization:

- Locate the fuel pump fuse or relay: Before starting the depressurization process, consult your vehicle’s manual to find the location of the fuel pump fuse or relay. This will vary depending on the make and model of your vehicle.

- Identify the correct fuse or relay: Once you’ve located the fuse box or relay panel, refer to the manual or the diagram on the underside of the fuse box cover to identify the specific fuse or relay for the fuel pump.

- Remove the fuel pump fuse or relay: Using a pair of pliers or fuse puller tool, carefully remove the fuel pump fuse or relay from its respective slot.

- Start the engine: Start your vehicle’s engine and allow it to idle. Keep the engine running until it stalls and stops completely. This process typically takes a few seconds to a minute, as the remaining fuel in the system is consumed.

- Turn off the ignition: Once the engine has stalled, turn off the ignition and remove the key. This ensures the fuel pump is completely shut off and pressure is relieved.

By following these step-by-step instructions, you can safely and effectively depressurize the fuel system before installing a new fuel filter. Remember to exercise caution and wear safety goggles or gloves during this process.

Disconnect The Old Fuel Filter

Disconnecting the old fuel filter is an important step in the process of installing a new one. This ensures that you can easily remove the old filter and replace it with a new one without any complications. In this section, we will discuss how to disconnect the fuel lines from the old filter and the methods for releasing fuel pressure before disconnection.

How to disconnect the fuel lines from the old filter

Disconnecting the fuel lines from the old filter requires careful attention and precision. Follow these steps to ensure a safe disconnection:

- Locate the old fuel filter under your vehicle. It is usually near the fuel tank or along the fuel line.

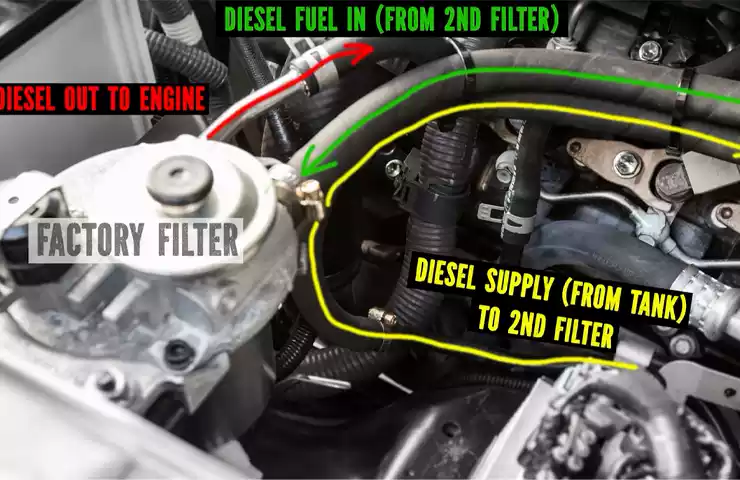

- Identify the fuel lines connected to the filter. There are usually two lines, one for the incoming fuel and the other for the outgoing fuel.

- Using a wrench or pliers, carefully loosen the fittings securing the fuel lines to the filter. Make sure to place a container underneath to catch any fuel that may spill.

- Once the fittings are loose, slowly pull the fuel lines away from the filter. Be cautious as there may still be some pressure in the lines.

- Remove any clips or clamps securing the fuel lines to the filter if necessary. This will ensure a smooth disconnection.

Methods for releasing fuel pressure before disconnection

Before disconnecting the fuel lines from the old filter, it is crucial to release the fuel pressure. This helps prevent any fuel from spraying or leaking out during the disconnection process. Here are two methods to release the fuel pressure:

Method 1: Depressurizing the fuel system

- Start by locating the fuel pump or fuel injectors fuse in the fuse box of your vehicle. Consult the owner’s manual for the exact location.

- Once you have located the fuse, carefully remove it to cut off the power to the fuel pump.

- Start the engine and allow it to run until it stalls. This will consume the remaining fuel in the lines and depressurize the system.

- Turn off the ignition and remove the key from the vehicle.

Method 2: Using a fuel pressure gauge

- Connect a fuel pressure gauge to the Schrader valve on the fuel rail, which is usually located near the engine.

- With the fuel pressure gauge attached, carefully loosen the Schrader valve to release the pressure. Make sure to have a suitable container to collect any fuel that may spray out.

- Once the pressure gauge indicates zero pressure, tighten the Schrader valve and disconnect the gauge.

By following these steps, you will be able to disconnect the old fuel filter safely and effectively. Remember to take necessary precautions and wear protective gloves to avoid contact with fuel.

Install The New Fuel Filter

After successfully removing the old fuel filter as outlined in the previous section, it is time to install the new one. This crucial step ensures that your vehicle’s fuel system functions optimally and delivers clean fuel to the engine. Follow the steps below for a smooth and effective installation process.

Proper alignment and positioning of the new fuel filter

When installing the new fuel filter, it is important to pay attention to its alignment and positioning. Here are the key considerations:

- Direction of flow: Take note of the direction in which fuel flows through the filter. Most filters have an arrow indicating this, ensuring proper fuel circulation. Ensure the arrow points towards the engine, allowing the fuel to flow in the correct direction.

- Mounting location: Typically, fuel filters are secured in place using brackets or clamps. Ensure that the new filter is mounted in the same position as the old one, aligning it properly with the mounting hardware. This guarantees a secure and stable installation.

- Clearance: Verify that the new fuel filter has sufficient clearance from other components in the engine compartment. This prevents potential damage or interference during operation. Double-check and adjust the positioning if necessary, taking into account the manufacturer’s recommendations.

Tips for ensuring a secure and leak-free installation

Installing a fuel filter requires attention to detail to prevent leaks and potential fuel system complications. Here are some valuable tips to ensure a secure and leak-free installation:

- Tighten fittings properly: Always use the appropriate tools and tighten the fittings securely. Avoid overtightening, as it can damage the filter or its connections. Use a torque wrench if necessary to achieve the recommended tightness specified by the vehicle manufacturer.

- Inspect O-rings and gaskets: Before installation, inspect the O-rings and gaskets on the new filter. Make sure they are in good condition, free from any damage or wear. Replace any faulty O-rings or gaskets, as they play a vital role in maintaining a tight seal.

- Apply lubricant: Apply a thin layer of appropriate lubricant (specified by the manufacturer) to the O-rings and gaskets. This helps create a proper seal and prevents them from drying out or cracking over time.

- Perform a visual inspection: Once the new fuel filter is installed, visually inspect the entire system for any signs of leakage. Check all connections, fittings, and hoses carefully. If you notice any leaks, address them promptly to avoid potential fuel system issues.

By following these guidelines, you can install a new fuel filter with proper alignment and positioning, ensuring a secure and leak-free installation. This will contribute to the overall performance and longevity of your vehicle’s fuel system.

Reconnect The Fuel Lines

After successfully removing the old fuel filter and installing the new one, it’s now time to reconnect the fuel lines to ensure smooth fuel flow. Follow these step-by-step instructions:

Step 1: Identify the Fuel Lines

Before reconnecting the fuel lines, it’s essential to know which line is the inlet and which is the outlet. Typically, the fuel lines are color-coded, with the inlet usually marked by a blue or green cap, and the outlet marked by a red or orange cap. If there are no color coding or markings, check the vehicle’s manual or consult a professional to identify the correct fuel lines.

Step 2: Inspect the Lines and Connections

Prior to reconnection, thoroughly inspect the fuel lines and connectors for any signs of damage or wear. Look for cracks, leaks, or loose connections. Ensure that both the fuel lines and the connectors are in good condition.

Step 3: Clean the Connections

Before reconnecting the fuel lines, it’s important to clean the connections to remove any dirt, debris, or rust that may have accumulated. Gently wipe the connections with a clean cloth or use a small brush to remove any obstructions. This will help create a tight and secure seal when reconnecting the lines.

Step 4: Secure the Connections

When reconnecting the fuel lines, align the connectors properly and apply gentle pressure until you hear a click or feel them snap into place. Ensure that the connections are secure and tight, as any looseness can result in fuel leaks.

Step 5: Test for Leaks

Once the fuel lines are reconnected, it’s crucial to test for any potential leaks before starting the vehicle. Wipe any areas where the fuel lines connect to the filter and inspect for drips or wet spots. If there are no leaks, you can proceed to the next steps of installing the new fuel filter.

Tip 1: Replace O-Rings or Gaskets

If you notice damaged, worn, or cracked o-rings or gaskets during the inspection, it is crucial to replace them with new ones. These components play a vital role in creating a tight seal and preventing fuel leaks.

Tip 2: Apply Lubrication

Before reconnecting the fuel lines, consider applying a thin layer of petroleum jelly or a specialized lubricant designed for fuel lines on the O-rings, gaskets, or connectors. This helps create a proper seal and makes it easier to slide the connections together smoothly.

Tip 3: Avoid Over-Tightening

While it’s important to ensure secure connections, be cautious not to over-tighten the fuel line connections. Excessive force can damage the connectors or cause them to crack, leading to fuel leaks. Tighten the connections snugly without applying excessive pressure.

Tip 4: Double Check for Proper Alignment

Before considering the fuel lines fully reconnected, double-check to ensure that the connectors are properly aligned. Misalignment can lead to leaks, so take the time to visually inspect and confirm that everything is properly connected before moving on.

Tip 5: Seek Professional Assistance if Unsure

If you are uncertain about any aspect of reconnecting the fuel lines or if you encounter unexpected difficulties, it is wise to seek the assistance of a professional mechanic. They have the experience and expertise to ensure the fuel lines are properly reconnected, minimizing the risk of fuel leaks.

Check For Leaks

One crucial step in the process of installing a fuel filter is to check for leaks. Even the smallest leakage can lead to a decrease in your vehicle’s performance or potentially become a safety hazard. In this section, we will guide you on how to inspect the fuel lines and connections for leaks, ensuring a smooth and secure installation.

How to Inspect the Fuel Lines and Connections for Leaks

Before proceeding with the fuel filter installation, it is important to thoroughly examine the fuel lines and connections for any signs of leakage. Follow these simple steps to ensure a comprehensive inspection:

- Start by visually inspecting all the fuel lines and connections. Look for any visible signs of cracks, corrosion, or loose fittings. Be sure to check both the inlet and outlet sides of the fuel filter, as well as any connections leading to and from the fuel tank.

- Next, run your fingers along the length of the fuel lines, feeling for any dampness or wetness that might indicate a leak. It’s best to wear protective gloves during this process to keep your hands clean and safe.

- Pay close attention to the fuel line connections, such as the hose clamps and fittings. Ensure that they are properly tightened and secure. If you notice any loose connections, tighten them using the appropriate tools.

- Inspect the fuel filter housing for any signs of leakage. Check the seals and gaskets for wear or damage. If necessary, replace them before proceeding with the installation.

Methods for Detecting and Resolving Leaks

If you detect any leaks during the inspection, it’s crucial to address them promptly. Here are a few methods you can utilize:

- Visual Inspection: If you spot any visible leaks, it is recommended to replace the damaged component or repair it as soon as possible.

- Pressure Testing: A pressure test can help identify hidden leaks that are not immediately visible. By applying pressure to the fuel system, you can detect even the smallest leaks, allowing for timely repairs.

- Sealant Application: For minor leaks or hairline cracks, a fuel line sealant can be applied as a temporary solution. However, it is important to note that a permanent fix, such as replacing the affected component, should be the ultimate goal.

- Professional Assistance: If you are unsure about resolving the leaks or lack the necessary tools and expertise, it is advisable to seek the help of a qualified mechanic or automotive professional.

By thoroughly inspecting the fuel lines and connections for leaks and taking appropriate measures to address any issues, you can install a fuel filter with confidence, ensuring optimal performance and safety for your vehicle.

Test The Fuel System Operation

Procedures for testing the fuel system after installing the new filter

Once you have successfully installed the new fuel filter, it is important to ensure that the fuel system is operating smoothly. Testing the fuel system operation will help you identify any issues or potential problems that may have arisen during the installation process. Follow these simple steps to effectively test the fuel system:

- Inspect for leaks: Start by visually inspecting the fuel filter and the surrounding area for any signs of fuel leakage. Look for drips, puddles or strong fuel odors. If you notice any leaks, tighten the connections or replace the necessary parts immediately.

- Turn on the ignition: Start by turning on the ignition key without starting the engine. This will allow the fuel pump to pressurize the fuel system.

- Listen for the fuel pump: Pay attention to any unusual sounds coming from the fuel pump. A properly functioning fuel pump should produce a low humming sound. If you hear any grinding or rattling noises, it could indicate a problem with the fuel pump and further inspection may be necessary.

- Check fuel pressure: If your vehicle has a Schrader valve on the fuel rail, you can use a fuel pressure gauge to measure the fuel pressure. Refer to your vehicle’s manual to determine the correct fuel pressure range. If the fuel pressure is too high or too low, it could be a sign of a faulty fuel pump or pressure regulator.

- Inspect fuel flow: Start the engine and observe the fuel flowing through the fuel lines. Look for a steady flow of fuel without any interruption. If you notice any blockages or weak flow, it could be an indication of a clogged fuel line or a problem with the fuel pump.

Common issues to look out for and how to troubleshoot them

While testing the fuel system, it is important to be aware of common issues that may occur and troubleshoot them accordingly. Here are some common issues and the steps you can take to fix them:

- Fuel leaks: If you notice any fuel leaks during the inspection, check the connections to ensure they are properly tightened. If the leak persists, replace the faulty parts or gaskets.

- Abnormal fuel pump noises: Unusual sounds coming from the fuel pump can indicate a failing pump. In this case, it is recommended to have the fuel pump inspected and replaced if necessary.

- Inadequate fuel pressure: If the fuel pressure is too low or too high, it could be due to a faulty fuel pump or pressure regulator. Consult a mechanic to diagnose and resolve the issue.

- Weak or interrupted fuel flow: A clogged fuel line or a malfunctioning fuel pump can cause weak or interrupted fuel flow. Clean or replace the fuel line and inspect the fuel pump for any issues.

By following these procedures for testing the fuel system operation and being aware of common issues, you can ensure a smooth installation of the new fuel filter and maintain the proper functioning of your vehicle’s fuel system.

Recommended Maintenance Schedule

One crucial aspect of maintaining your vehicle’s performance and longevity is adhering to a recommended maintenance schedule. By following this schedule, you ensure that all the vital components of your vehicle receive the attention they need to function optimally. Among these essential components is the fuel filter, which plays a crucial role in preventing contaminants from entering your engine. Regularly replacing your fuel filter is vital to ensure clean fuel reaches your engine, maximizing its efficiency and preventing potential damage. In this article, we will explore the recommended maintenance schedule for fuel filter replacement, factors that may require more frequent filter replacements, and the importance of staying on top of this maintenance task.

How often the fuel filter should be replaced

The frequency of fuel filter replacement depends on several factors, including the make and model of your vehicle, driving conditions, and the type of fuel you use. As a general rule of thumb, it is recommended to replace your fuel filter every 30,000 to 40,000 miles or every 3 years, whichever comes first. However, it is important to consult your vehicle’s owner manual for manufacturer-specific guidelines. Adhering to these recommendations ensures that your fuel filter remains in optimal condition and performs its filtration function effectively.

Factors that may require more frequent filter replacements

While the recommended mileage or time interval serves as a baseline for fuel filter replacement, certain factors may necessitate more frequent filter replacements to maintain peak performance. These factors include:

- Driving in dusty or heavily polluted areas: If your vehicle is regularly subjected to dusty or heavily polluted environments, the fuel filter can become clogged at a faster rate. In such cases, it may be beneficial to inspect and replace the filter more frequently to prevent a decrease in engine performance and potential fuel delivery issues.

- Using low-quality fuel: Low-quality fuel often contains higher levels of contaminants, which can accelerate the buildup of debris in the fuel filter. Consider replacing the filter more frequently if you frequently use fuel from questionable sources or regions where fuel quality is a concern.

- Experiencing engine performance issues: If you notice a decline in your vehicle’s performance, such as reduced fuel efficiency, sluggish acceleration, or stalling, it may indicate a clogged or malfunctioning fuel filter. In such cases, it is recommended to inspect and replace the filter as necessary to restore optimal engine performance.

In conclusion, adhering to the recommended maintenance schedule for fuel filter replacement is essential for maintaining your vehicle’s performance and preventing potential engine damage. By following the mileage and time guidelines provided by your vehicle’s manufacturer and considering factors that may require more frequent replacements, you can ensure that your fuel filter functions optimally, effectively filtering out contaminants and supplying clean fuel to your engine. Stay proactive in maintaining your vehicle’s fuel filter, and enjoy smoother drives and improved fuel efficiency.

Signs Of A Failing Fuel Filter

Indications that your fuel filter needs replacement

Regular maintenance and timely replacement of your car’s fuel filter are crucial for keeping your engine running smoothly. A failing fuel filter can lead to various issues, including reduced fuel efficiency, engine misfires, and even engine stalling. It is important to be aware of the signs that indicate your fuel filter may be reaching the end of its lifespan.

1. Poor engine performance

One of the most common signs of a failing fuel filter is reduced engine performance. If you notice a decrease in acceleration or overall power, it could be due to a clogged or dirty fuel filter. A restricted fuel flow can lead to insufficient fuel reaching the engine, causing a noticeable drop in performance.

2. Difficulty starting the engine

If your car is having trouble starting, especially after sitting for an extended period, a clogged fuel filter may be the culprit. A blocked filter can restrict the flow of fuel to the engine, making it harder for the car to ignite and start. If you consistently experience difficulty starting your engine, it is advisable to inspect and replace the fuel filter.

3. Engine misfires or stalling

A failing fuel filter can also cause engine misfires or intermittent stalling. When the filter is clogged, the engine may not receive a consistent supply of fuel, leading to misfires or sudden shutdowns. If you notice your engine hesitating, sputtering, or randomly stalling while driving, it is essential to address the fuel filter issue promptly.

4. Decreased fuel efficiency

If you find that your car’s fuel efficiency has significantly decreased, it could be an indication that the fuel filter is not allowing proper fuel flow. A clogged or dirty filter forces the engine to work harder to compensate for the lack of fuel, resulting in increased fuel consumption. If you’ve noticed a sudden drop in your mileage, it’s worth considering a fuel filter replacement.

Troubleshooting steps when experiencing fuel filter issues

When you suspect that your fuel filter is causing problems in your vehicle, there are a few troubleshooting steps you can take before deciding to replace it. These steps may help identify the cause of the issue and provide a temporary solution, although replacing the filter is ultimately necessary for optimal performance.

1. Check for fuel flow restrictions

If you’re experiencing fuel delivery problems, it’s important to check for any restrictions in the fuel system. Start by inspecting the fuel lines for kinks, bends, or leaks. Also, check if the fuel pump is functioning properly and providing consistent fuel pressure. Identifying and addressing any blockages or issues within the fuel system can alleviate fuel filter-related problems.

2. Clean or replace the fuel filter

If the fuel filter is suspected to be the cause of the issues and inspection reveals it is dirty or clogged, cleaning or replacing it is recommended. Cleaning can be done using specialized fuel system cleaners or by backwashing the filter to remove debris. However, if the filter is severely clogged, replacement is usually the best course of action to ensure proper filtration and fuel flow.

3. Professional inspection and replacement

If troubleshooting steps and cleaning the fuel filter do not resolve the issues, it is advisable to seek professional assistance. An experienced mechanic can perform thorough diagnostics to determine the root cause of the problem and ensure that the fuel filter is replaced correctly. Professional guidance helps to avoid further complications and ensures your vehicle’s fuel system functions optimally.

Fuel Filter Replacement Process

Step-by-step instructions for replacing a fuel filter

Replacing a fuel filter is an important maintenance task that ensures the proper functioning of your vehicle’s fuel system. Here are the step-by-step instructions to guide you through the fuel filter replacement process:

- Park your vehicle in a well-ventilated area: Begin by finding a suitable location to perform the replacement. Make sure it is well-lit and has enough space for you to work comfortably.

- Locate the fuel filter: Refer to your vehicle’s owner manual to find the exact location of the fuel filter. Typically, it is found along the fuel line, between the fuel tank and the engine.

- Prepare the necessary tools: Gather the tools you’ll need for the replacement, including safety goggles, gloves, a wrench or socket set, and a container to catch any fuel spills.

- Relieve fuel system pressure: Before disconnecting any components, relieve the pressure in the fuel system by removing the fuel pump fuse or relay, and then starting the engine until it stalls. This step prevents fuel from spraying out when you disconnect the filter.

- Disconnect the fuel lines: Use a wrench or socket set to loosen and remove the fittings connecting the fuel lines to the filter. Be prepared for some fuel to leak out.

- Remove the old fuel filter: Carefully detach the old filter from its mounting bracket or holder. Check for any leakage or damage that may have occurred over time.

- Install the new fuel filter: Position the new filter in place, making sure it fits securely. Double-check that the arrow on the filter is pointing towards the engine, ensuring correct fluid flow.

- Reconnect the fuel lines: Attach the fuel lines to the new filter, tightening the fittings with a wrench or socket set.

- Restore fuel system pressure: Put back the fuel pump fuse or relay and turn the ignition on without starting the engine. This will pressurize the fuel system.

- Check for leaks: Inspect all connections and the filter for any signs of fuel leakage. Address any issues before proceeding.

- Start the engine and test: Start your vehicle’s engine and let it run for a few minutes to ensure the new filter is functioning properly. Monitor for any abnormal behavior.

Tips for easier and efficient replacement

Here are some tips to help you make the fuel filter replacement process easier and more efficient:

- Refer to the manufacturer’s instructions: Always consult your vehicle’s owner manual or the filter’s documentation for specific guidelines and requirements.

- Replace the fuel filter regularly: It is recommended to replace the fuel filter according to the manufacturer’s recommended intervals or guidelines, typically every 30,000 to 50,000 miles or as stated in the user manual.

- Consider replacing the filter with a high-quality brand: Opt for a reputable brand that provides good filtration and durability, ensuring the longevity of your fuel system.

- Inspect other fuel system components: While replacing the fuel filter, take the opportunity to check other components, such as the fuel lines, for any signs of wear or damage. Replace parts as needed.

- Properly dispose of the old filter: Remove the old filter and dispose of it in compliance with local environmental regulations or guidelines. Avoid simply throwing it in the trash.

- Wear protective gear: Protect yourself during the replacement process by wearing safety goggles and gloves. This helps prevent any fuel or debris from coming into contact with your eyes or skin.

- Have a fire extinguisher nearby: Though rare, it is always better to be prepared. Keep a fire extinguisher easily accessible in case of any fuel-related accidents or emergencies.

Following these step-by-step instructions and tips will help you successfully replace your vehicle’s fuel filter, ensuring a well-maintained fuel system and optimal engine performance. Remember to prioritize safety throughout the process and consult a professional if you encounter any difficulties or uncertainties.

Frequently Asked Questions On How To Install A Fuel Filter

What Is The Correct Way To Install Fuel Filter?

To properly install a fuel filter, follow these steps: 1. Locate the old filter and remove it by disconnecting the fuel lines. 2. Install the new filter, ensuring it’s in the correct position and the arrows match with fuel flow direction.

3. Reconnect the fuel lines securely. 4. Start the engine and check for leaks. 5. Finally, confirm a successful installation by inspecting the filter for any signs of leakage.

Can I Replace My Fuel Filter Myself?

Yes, you can replace your fuel filter yourself. It is a relatively simple task that can be done with basic tools. Make sure to consult your vehicle’s manual for specific instructions. Remember to wear protective gloves and eyewear when working with fuel.

What Are Symptoms Of Bad Fuel Filter?

Symptoms of a bad fuel filter include engine misfires, decreased engine performance, stalling, difficulty starting, and poor fuel efficiency.

How Long Does It Take To Change A Fuel Filter?

It typically takes around 30 minutes to an hour to change a fuel filter.

Conclusion

Installing a fuel filter is a simple yet essential task for maintaining your vehicle’s performance and longevity. By following the step-by-step guide outlined in this blog post, you can ensure the efficient flow of clean fuel to your engine, reducing the risk of damage and maximizing fuel efficiency.

Regularly replacing your fuel filter is a small investment that can yield significant benefits in the long run. So, take charge of your vehicle’s health and give it the care it deserves.