To install a mechanical fuel pump on a Ford, begin by locating the old pump and removing it. Then, attach the new pump using the appropriate bolts and gaskets, ensuring a secure connection.

Tighten the bolts and reattach the fuel lines, making sure they are properly connected and tightened. Finally, test the new pump for functionality by turning on the ignition and checking for any leaks.

Understanding The Importance Of A Mechanical Fuel Pump

When it comes to older Ford vehicles, understanding the importance of a mechanical fuel pump is crucial. This vital component plays a crucial role in ensuring that fuel is properly delivered to the engine, allowing it to run smoothly and efficiently.

Why mechanical fuel pumps are essential in older Ford vehicles

In older Ford vehicles, mechanical fuel pumps are essential for several reasons. These vehicles were designed with this type of fuel pump in mind, and therefore rely on it for proper fuel delivery. Here are a few key reasons why mechanical fuel pumps are essential:

- Compatibility: Mechanical fuel pumps are specifically designed to work with the engines and fuel systems found in older Ford vehicles. Their construction and functionality are tailored to meet the unique requirements of these engines, ensuring optimal performance and fuel delivery.

- Simplicity: Mechanical fuel pumps are known for their simplicity. Unlike their electric counterparts, which can be more complex and require additional wiring and components, mechanical fuel pumps operate purely through mechanical action. This simplicity allows for easier installation, maintenance, and troubleshooting when compared to electric fuel pumps.

- Durability: Mechanical fuel pumps are known for their durability. They are typically made from robust materials such as cast iron or aluminum, which can withstand the demanding conditions of engine operation. Additionally, their mechanical design is less prone to failure compared to electric fuel pumps, making them a reliable choice for older Ford vehicles.

Advantages of mechanical fuel pumps over electric fuel pumps in certain situations

While electric fuel pumps have become more prevalent in modern vehicles, there are still situations where mechanical fuel pumps hold distinct advantages. Understanding these advantages can help you make an informed decision when it comes to installing a fuel pump in your older Ford vehicle. Here are a few advantages of mechanical fuel pumps:

- Reliability: Mechanical fuel pumps are known for their reliability. Their simple mechanical design means that there are fewer components that can malfunction or fail. This reliability is particularly beneficial in situations where the vehicle may experience rough or off-road conditions.

- Compatibility with carbureted engines: Many older Ford vehicles are equipped with carbureted engines, which rely on mechanical fuel pumps for proper fuel delivery. Electric fuel pumps are not compatible with carbureted engines without additional modifications, making mechanical fuel pumps the preferred choice in these instances.

- Cost: In certain situations, mechanical fuel pumps can be a more cost-effective option when compared to electric fuel pumps. They tend to be more affordable upfront, and their simpler design means that maintenance and repair costs can be lower as well.

In conclusion, mechanical fuel pumps play a vital role in older Ford vehicles. They are essential for proper fuel delivery, ensuring that the engine runs smoothly and efficiently. With their compatibility, simplicity, durability, reliability, compatibility with carbureted engines, and cost advantages in certain situations, mechanical fuel pumps remain a wise choice for older Ford vehicles.

Tools And Materials Required For The Installation Process

When installing a mechanical fuel pump on your Ford vehicle, it is crucial to have the right tools and materials on hand. This ensures a smooth and successful installation process, preventing any delays or complications.

The necessary tools and equipment needed

To install a mechanical fuel pump on your Ford, you will need the following tools and equipment:

- Socket wrench set: A socket wrench set will be used to remove bolts and fasteners.

- Screwdriver set: A set of screwdrivers will be needed to handle various types of screws and fasteners.

- Torque wrench: A torque wrench is essential for tightening bolts to the manufacturer’s specifications.

- Jack and jack stands: A jack and jack stands will be needed to lift and support the vehicle safely during the installation process.

- Fuel line disconnect tool: This tool helps in disconnecting the fuel lines without damaging them.

- Gasket scraper: A gasket scraper is necessary to remove any old gasket material from the engine.

- New fuel pump: Make sure to have a compatible mechanical fuel pump specific to your Ford vehicle.

- Fuel line clamps: These clamps will help secure the fuel lines in place and prevent any potential leaks.

- Pliers: Pliers are useful for gripping and bending various components during the installation process.

- New gaskets: Have a set of new gaskets ready to ensure a proper seal and prevent any fuel leaks.

- Shop rags or towels: It’s always a good idea to have some shop rags or towels handy for cleaning up any spills or messes.

Recommended materials for a successful installation process

In addition to the tools mentioned above, it is recommended to gather the following materials for a successful installation process:

- Threadlocker: Applying threadlocker to the bolts will help prevent them from loosening over time.

- High-temperature silicone sealant: This sealant will ensure a tight seal between the fuel pump and the engine block.

- Engine degreaser: Having engine degreaser on hand will facilitate the cleaning process before the installation.

- Fuel system cleaner: It’s a good idea to use a fuel system cleaner to remove any debris or build-up in the fuel lines.

- Protective gloves and safety glasses: Wear protective gloves and safety glasses to keep your hands and eyes safe during the installation process.

By having the necessary tools and materials ready, you can proceed with confidence during the mechanical fuel pump installation process on your Ford. Remember to take your time, follow the manufacturer’s instructions, and ensure proper safety precautions for a successful and hassle-free installation.

Step 1: Preparing For The Installation

Before you can start installing a mechanical fuel pump on your Ford vehicle, it’s important to make sure you have all the necessary parts and a clean and safe working environment. This step-by-step guide will walk you through the process of preparing for the installation to ensure a smooth and successful fuel pump replacement.

Gathering all the required parts

The first step in preparing for the installation is to gather all the required parts. Here are the items you will need for this project:

| Parts | Quantity |

|---|---|

| Replacement mechanical fuel pump | 1 |

| Gasket | 1 |

| Socket set | 1 |

| Torque wrench | 1 |

| Screwdriver | 1 |

| Rags or paper towels | As needed |

Make sure you have all the parts listed above before you begin the installation. This will help ensure that you have everything you need at hand and prevent any delays or frustrations during the process.

Ensuring a clean and safe working environment

Next, it’s essential to ensure that you have a clean and safe working environment. Follow these steps to create an optimal workspace:

- Choose a well-ventilated area: Find a location with proper ventilation to ensure the fumes and potentially hazardous fuels are dispersed.

- Clean the area: Before starting, clean the surrounding area to remove any dirt, debris, or potential contaminants that could interfere with the installation process.

- Eliminate potential fire hazards: Ensure there are no open flames, sparks, or electrical equipment nearby that could cause a fire or ignite fuel.

- Have a fire extinguisher nearby: As a safety precaution, have a fire extinguisher readily available in case of an emergency.

By taking the time to gather all the required parts and creating a clean and safe working environment, you’re setting yourself up for a successful mechanical fuel pump installation. Now that you’ve completed the preparation, you’re ready to move on to the next step: removing the old fuel pump.

Step 2: Removing The Old Fuel Pump

Now that you have located the current fuel pump, it’s time to roll up your sleeves and get rid of the old one. This step is crucial in the installation process, as it ensures a clean and smooth transition to the new mechanical fuel pump for your Ford vehicle. Follow the instructions below to efficiently remove the old fuel pump.

Locating the current fuel pump

Before you can begin the removal process, you need to locate the current fuel pump in your Ford vehicle. The exact location may vary depending on the model and year of your vehicle, but it can usually be found near the engine block or on the side of the engine. Refer to your vehicle’s manual or conduct a quick online search to find the specific location for your Ford model.

Properly disconnecting fuel lines and electrical connections

Once you have located the fuel pump, the next crucial step is to disconnect the fuel lines and electrical connections. This ensures that no fuel or electrical power is being supplied to the old pump, enabling a safe removal.

To disconnect the fuel lines:

- Identify the fuel line connectors.

- Using a fuel line disconnect tool, carefully detach the fuel lines from the old pump.

- Be prepared for any residual fuel to leak out, so keep a rag or a fuel catch pan handy.

To disconnect the electrical connections:

- Locate the electrical connectors attached to the old fuel pump.

- Gently disconnect and remove the electrical connectors, ensuring not to damage any wiring.

Remember, safety should always be your top priority when working with fuel-related components. It’s crucial to take proper precautions to prevent any accidents or injuries during the removal process.

With the fuel lines and electrical connections successfully disconnected, you have completed the second step in installing a mechanical fuel pump for your Ford. Stay tuned for the next step and ensure your journey towards a more efficient fuel system continues smoothly!

Step 3: Choosing The Right Replacement Fuel Pump

Now that you understand the installation process and have removed the old fuel pump, it’s time to choose the appropriate replacement for your Ford vehicle. Selecting the right mechanical fuel pump is crucial to ensure optimal performance and compatibility.

Understanding the Compatibility Requirements

When it comes to choosing a replacement fuel pump, it’s important to understand the compatibility requirements for your Ford vehicle. Factors such as the make, model, and year of your vehicle, as well as the engine size, are essential in determining the right fuel pump for your specific needs.

To find the correct fuel pump, refer to your vehicle’s manual or consult with a trusted mechanic. They can provide you with the necessary information regarding the compatible fuel pump options for your Ford vehicle.

Selecting the Appropriate Mechanical Fuel Pump

Once you have the necessary compatibility requirements, it’s time to select the appropriate mechanical fuel pump for your Ford. Consider the following factors to ensure a suitable replacement:

- Manufacturer: Choose a fuel pump manufactured by a reputable brand known for producing high-quality automotive parts. This ensures reliability and durability.

- Flow Rate: Determine the required flow rate of the fuel pump, which is measured in gallons per hour (GPH). Consider factors such as the engine size, horsepower, and potential modifications when selecting the appropriate flow rate.

- Pressure: Look for a fuel pump that can deliver the required pressure for your Ford vehicle. Pressure is measured in pounds per square inch (PSI) and varies depending on the engine type.

- Mounting Style: Consider the mounting style of the fuel pump, whether it’s a block-mounted or pushrod-style pump, to ensure compatibility with your Ford vehicle’s engine configuration.

By considering these factors, you can confidently choose the right mechanical fuel pump for your Ford vehicle. It’s always a good practice to consult with an experienced mechanic or seek advice from knowledgeable automotive professionals to ensure a proper fit.

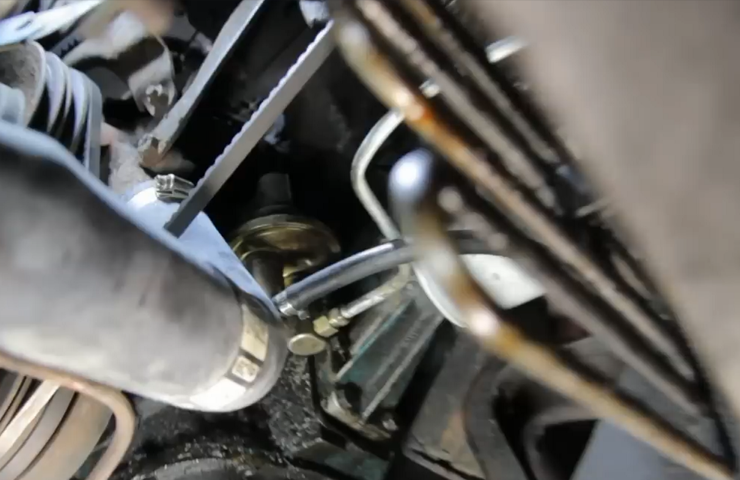

Step 4: Installing The New Fuel Pump

Mounting the new fuel pump in the correct position

Once you have removed the old fuel pump, it’s time to install the new one. Mounting the new fuel pump in the correct position is crucial for its proper functioning. Here’s how you can do it:

- Start by finding the mounting holes on the engine block. These holes are typically located on the side of the engine, near the fuel pump pushrod opening. Make sure to clean the mounting surface and remove any debris or old gasket material.

- Place the new fuel pump onto the mounting surface, lining up the mounting holes with the holes on the engine block. Ensure that the pump is aligned properly and sits flush against the surface.

- Secure the fuel pump in place by inserting and tightening the mounting bolts. Use a torque wrench to tighten the bolts to the manufacturer’s specifications. Tightening the bolts evenly and to the correct torque is essential to prevent leaks and ensure a secure fit.

- Inspect the gasket that came with the new fuel pump. If necessary, apply a thin layer of gasket sealant or grease to the gasket to ensure a proper seal. Place the gasket onto the mounting surface, aligning it with the holes.

- Carefully place the fuel pump gasket onto the mounting surface, aligning it with the holes. Ensure that the gasket is positioned correctly to create a seal between the fuel pump and the engine block.

- Once the gasket is in place, carefully slide the fuel pump pushrod into the opening on the engine block. Ensure that the pushrod is properly aligned and seated securely in the fuel pump. This will ensure proper functioning of the pump.

- Double-check that the fuel pump is securely mounted and that all the bolts are properly tightened. Inspect the area around the fuel pump to ensure that there are no signs of leaks or loose connections.

Connecting the fuel lines and electrical connections

Now that the new fuel pump is properly mounted, it’s time to connect the fuel lines and electrical connections. Follow these steps to ensure a secure and proper connection:

1. Attach the fuel lines to the fuel pump. Inspect the fuel lines for any damage or signs of wear, and replace them if necessary. Ensure that the fuel lines are connected securely to the appropriate ports on the fuel pump.

2. Use hose clamps to secure the fuel lines to the fuel pump, ensuring a tight and leak-free connection. Tighten the hose clamps using a screwdriver or pliers, but be careful not to overtighten and damage the fuel lines.

3. Connect the electrical connections to the fuel pump. These connections may include wires for powering the fuel pump and any additional sensors or switches. Follow the manufacturer’s instructions or the wiring diagram for your specific vehicle to ensure proper connection.

4. Inspect all the connections to make sure they are secure and properly tightened. Double-check for any signs of leaks or loose fittings. Any loose connections or leaks can result in poor fuel delivery and affect the performance of your vehicle.

By following these steps, you can successfully install a mechanical fuel pump on your Ford vehicle. Ensure that every step is executed correctly, paying attention to details such as mounting position, securing bolts, properly aligned gaskets, and well-connected fuel lines and electrical connections. Doing so will help ensure the optimal performance of your vehicle’s fuel delivery system.

Step 5: Testing And Adjusting The New Fuel Pump

After successfully installing the mechanical fuel pump on your Ford vehicle, it’s important to properly test and adjust it to ensure optimal performance. This will help in priming the fuel system and checking for leaks, as well as adjusting the fuel pressure if necessary. Let’s walk through these crucial steps to complete the installation process.

Priming the Fuel System and Checking for Leaks

Once the new mechanical fuel pump is installed, it is essential to prime the fuel system before starting the engine. This process helps eliminate any air bubbles or gaps in the system, ensuring a smooth and uninterrupted fuel flow. To prime the fuel system, follow the steps below:

- Ensure that the fuel tank is filled with an adequate amount of fuel.

- Disconnect the fuel line from the carburetor or fuel injection system.

- Carefully pour a small amount of clean fuel into the fuel line until it reaches the fuel pump.

- Reconnect the fuel line to the carburetor or fuel injection system.

- Check for any leaks along the fuel line or connections. If you notice any leaks, tighten the fittings or replace damaged parts accordingly.

By following these steps, you’ll effectively prime the fuel system and ensure that there are no leaks, which can cause fuel inefficiency and potential hazards.

Adjusting the Fuel Pressure if Necessary

After priming the fuel system, it’s essential to check if the fuel pressure is within the recommended range for your Ford vehicle. This step helps ensure that the engine receives the correct amount of fuel for optimal performance. To adjust the fuel pressure, follow the steps below:

- Locate the fuel pressure adjustment screw or regulator on the mechanical fuel pump.

- Using a fuel pressure gauge, measure the current fuel pressure.

- Refer to your vehicle’s manual or specifications to determine the appropriate fuel pressure range.

- If the measured fuel pressure is outside the recommended range, carefully adjust the fuel pressure screw or regulator accordingly.

- Monitor the fuel pressure using the gauge and make small adjustments as needed until it falls within the correct range.

It’s crucial to be cautious while adjusting the fuel pressure, as too high or too low pressure can negatively impact the engine’s performance. Taking the time to properly adjust the fuel pressure will ensure optimal fuel delivery and enhance your Ford vehicle’s overall performance. In conclusion, testing and adjusting the new mechanical fuel pump on your Ford vehicle is a vital step to complete the installation process. By priming the fuel system and checking for leaks, as well as adjusting the fuel pressure if necessary, you’ll ensure a smooth and reliable fuel delivery system. Take your time to properly test and adjust the new fuel pump, as this will contribute to the efficient operation of your Ford vehicle.

Troubleshooting Common Issues With Mechanical Fuel Pump Installation

Installing a mechanical fuel pump on a Ford vehicle may seem like a straightforward task, but sometimes issues can arise that require troubleshooting. It’s important to identify potential problems and their solutions to ensure a successful installation. In this section, we will discuss common problems that may occur during the installation process and provide tips for troubleshooting these challenges.

Identifying potential problems and their solutions

Before diving into the troubleshooting process, it’s crucial to identify potential problems that can occur during the mechanical fuel pump installation on a Ford vehicle. By recognizing these issues beforehand, you can save both time and frustration.

| Problem | Solution |

|---|---|

| The fuel pump is leaking after installation | Check the gaskets for any damage or improper installation. Replace any damaged gaskets and ensure proper alignment during installation. |

| Fuel flow is inadequate | Inspect the fuel line for any obstructions or clogs. If necessary, replace the fuel line and ensure it is correctly connected to the fuel pump and carburetor. |

| Engine fails to start after installation | Check the fuel pump pushrod for proper installation and alignment. Also, verify that the fuel pump lever is properly engaged with the engine camshaft. |

Tips for troubleshooting any challenges during installation

When faced with challenges during the mechanical fuel pump installation on a Ford vehicle, there are several tips you can follow to troubleshoot and overcome these obstacles.

- Double-check the installation steps: Review the installation instructions provided by the manufacturer and ensure that each step has been completed correctly.

- Inspect all components: Carefully examine the fuel pump, gaskets, and connections for any signs of damage or improper alignment.

- Verify fuel line connections: Confirm that the fuel line is securely connected to both the fuel pump and the carburetor to ensure proper fuel flow.

- Test for fuel pressure: Use a fuel pressure gauge to check if the mechanical fuel pump is delivering adequate pressure to the carburetor.

- Consult a professional: If troubleshooting efforts do not solve the problem, consulting a professional mechanic or Ford specialist can provide further assistance.

By following these tips and being proactive in your troubleshooting efforts, you can overcome common challenges that may arise during the mechanical fuel pump installation on your Ford vehicle. Remember to always refer to the manufacturer’s instructions and seek professional help if needed.

Frequently Asked Questions Of How To Install A Mechanical Fuel Pump On Ford

Can You Install A Mechanical Fuel Pump Wrong?

Yes, it is possible to install a mechanical fuel pump incorrectly. It is important to carefully follow the installation instructions to ensure proper functioning. Incorrect installation can lead to fuel delivery issues and potentially damage the engine.

Do I Need To Prime My Mechanical Fuel Pump?

No, mechanical fuel pumps do not require priming. They are self-priming and designed to draw fuel from the tank without any additional intervention. Simply start the engine, and the pump will automatically draw fuel to the engine.

How Do You Remove A Mechanical Fuel Pump?

To remove a mechanical fuel pump, follow these steps: First, locate the fuel pump on your vehicle. Use a wrench to disconnect the fuel lines. Disconnect the electrical connections to the pump. Remove any mounting bolts holding the pump in place.

Finally, pull the pump out of its housing.

Why Is There No Fuel To My Mechanical Fuel Pump?

The fuel pump might not be receiving fuel due to a blockage in the fuel line, a faulty fuel pump, or a clogged fuel filter. Check for these issues and address them accordingly to restore fuel flow to your mechanical fuel pump.

Conclusion

Installing a mechanical fuel pump on a Ford is a relatively straightforward process that can help improve the performance and reliability of your vehicle’s fuel system. By following the steps outlined in this guide, you can ensure a successful installation that will keep your Ford running smoothly.

Remember to take your time, follow safety precautions, and refer to the manufacturer’s instructions for any specific details. With a little bit of effort and know-how, you’ll have your mechanical fuel pump installed and ready to go in no time.