Choosing the correct distributor is essential for ensuring the reliable functioning of a 5.7 Vortec engine. The distributor acts as the central hub for the engine’s ignition system, distributing high voltage sparks to the appropriate cylinders at the right time. Inadequate spark or incorrect timing can lead to misfires, reduced power, and decreased fuel efficiency. Therefore, selecting a distributor that is specifically designed for the 5.7 Vortec engine is vital for optimal performance.

Factors to consider when selecting a distributor

When choosing a distributor for your 5.7 Vortec engine, several factors need to be taken into account:

- Compatibility with the engine’s ignition system

- Distributor material and build quality

- Performance features and options available

Let’s delve into each of these factors in more detail.

Compatibility with the engine’s ignition system

The distributor’s compatibility with the engine’s ignition system is crucial for seamless integration. Different distributors may have varying specifications, such as the number of terminals or the type of ignition control module. Therefore, it is essential to choose a distributor that matches the requirements of the 5.7 Vortec engine’s ignition system. This ensures proper connectivity, reliable spark delivery, and efficient engine performance.

Distributor material and build quality

The material and build quality of the distributor are important considerations for longevity and durability. Distributors that are made from high-quality materials such as aluminum or stainless steel offer better resistance to heat, corrosion, and wear. Additionally, distributors with precision machining and superior craftsmanship ensure smooth rotation, accurate spark timing, and overall reliability. Opting for a distributor with excellent material and build quality can help you avoid premature failures and costly repairs in the long run.

Performance features and options available

Lastly, consider the performance features and options available for the distributor. Different distributors may offer additional features such as adjustable advance curves, vacuum advances, or even electronic ignition systems. These features can enhance the engine’s performance, fuel efficiency, and drivability. Assess your specific needs and preferences to determine which performance features are most suitable for your 5.7 Vortec engine.

In conclusion, choosing the right distributor for your 5.7 Vortec engine is vital for optimal performance. Consider factors such as compatibility with the ignition system, distributor material and build quality, and the performance features and options available. By making an informed choice, you can ensure reliable ignition, improved power delivery, and an overall enhanced driving experience.

Preparing For The Installation

Before you can install a distributor in your 5.7 Vortec engine, it is important to properly prepare for the installation process. This involves gathering the necessary tools and equipment, ensuring a safe work environment, and removing any obstructions that may hinder the installation process.

Gathering the necessary tools and equipment

Gathering the necessary tools and equipment beforehand will save you time and frustration during the installation process. Here is a list of the essential tools and equipment you will need:

| Tools | Equipment |

|---|---|

| Socket setWrench setScrewdriver setIgnition timing light | Clean clothShop ragPenetrating oilOil pan |

Make sure all the tools and equipment are easily accessible before you begin the installation process. This will help you work efficiently and smoothly.

Ensuring a safe work environment

Prioritizing safety is crucial when working with engines. Here are some steps to ensure a safe work environment:

- Wear appropriate safety gear, such as gloves and safety glasses, to protect yourself from any potential hazards.

- Work in a well-ventilated area to prevent the accumulation of harmful fumes.

- Ensure the engine is turned off and the ignition key is removed before starting the installation process.

- Keep fire extinguisher nearby in case of any emergency.

By taking these precautions, you can minimize the risk of accidents and injuries during the installation process.

Removing any obstructions that may hinder the installation

process

Prior to installing the distributor, it is important to remove any obstructions that may hinder the installation process. Perform the following steps:

- Clean the surrounding area around the distributor housing to remove any debris or dirt that may affect the installation.

- Inspect the distributor cap and rotor for any signs of wear or damage. If necessary, replace them before proceeding with the installation.

- Disconnect any electrical connections, such as spark plug wires or sensors, that may interfere with the installation process.

By removing these obstructions, you can ensure a smooth and hassle-free installation of the distributor in your 5.7 Vortec engine.

Step-By-Step Installation Process

Installing a distributor in a 5.7 Vortec engine requires a step-by-step process to ensure proper installation and timing. Follow these instructions carefully to successfully install the new distributor:

1. Draining the coolant and disconnecting the battery

Before starting the installation process, it’s important to drain the coolant and disconnect the battery to ensure safety and prevent any accidental leaks or electrical mishaps.

2. Removing the old distributor

Locate the old distributor in the engine and carefully disconnect any electrical connections and vacuum hoses connected to it. Next, loosen the distributor hold-down bolt and remove the old distributor from the engine block.

3. Locating the distributor’s position in the engine

Take note of the exact position of the old distributor in the engine. This will help in aligning the new distributor correctly during the installation process.

4. Marking the position of the rotor and distributor housing

Before removing the old distributor, mark the position of the rotor and the distributor housing. This will ensure proper alignment when installing the new distributor.

5. Disconnecting the electrical connections and vacuum hoses

Disconnect any remaining electrical connections and vacuum hoses that are still attached to the old distributor. Make sure to label or remember the connections for easy reconnection later.

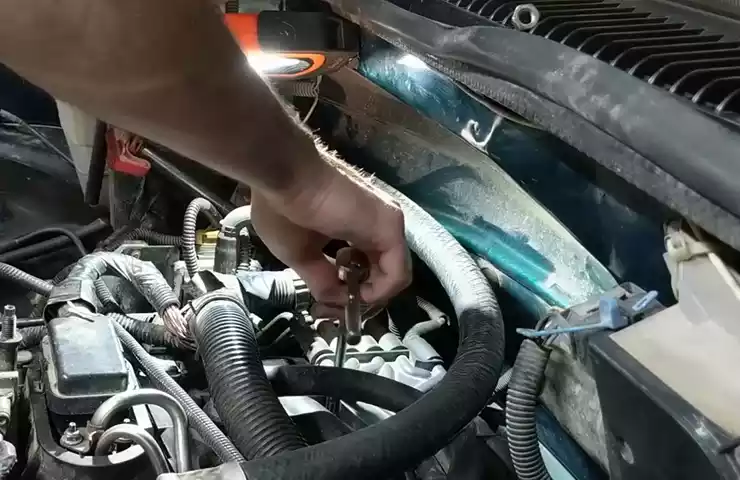

6. Loosening the distributor hold-down bolt and removing the distributor

Loosen the distributor hold-down bolt further and carefully remove the old distributor from the engine block.

7. Preparing the new distributor for installation

Before installing the new distributor, ensure that it is compatible with the gear on the engine block. Check for proper gear compatibility to avoid any issues during the installation process.

8. Applying lubrication to the distributor gear and housing

Apply a small amount of lubrication to both the distributor gear and housing. This will help in smooth movement and prevent any damage during installation.

9. Installing the new distributor

Align the rotor and distributor housing with the previously marked positions. Insert the new distributor carefully into the engine block, making sure it fits securely.

10. Securing the distributor with the hold-down bolt

Tighten the distributor hold-down bolt to secure the new distributor in place. Ensure it is tightened properly but not overly tightened to prevent any damage to the engine block.

11. Reconnecting the electrical connections and vacuum hoses

Reconnect the electrical connections and vacuum hoses that were previously disconnected. Use the labels or notes made earlier to correctly reconnect each connection.

12. Timing the distributor

Timing the distributor is important to ensure proper engine performance. Set the engine to the correct timing position and adjust the distributor to align with the correct timing marks.

13. Reassembling and testing

Reinstall any removed components and connections, making sure everything is properly secured. Refill the coolant and reconnect the battery. Conduct a thorough inspection to check for any leaks or issues. Finally, start the engine and test its performance.

Congratulations! You have successfully installed a new distributor in your 5.7 Vortec engine. Following this step-by-step installation process will ensure smooth operation and optimal engine performance.

Troubleshooting And Maintenance Tips

When it comes to installing a distributor in a 5.7 Vortec engine, troubleshooting and maintenance are key to ensuring optimal performance. In this section, we will explore common issues that may arise during or after the installation process, as well as troubleshooting steps for misalignment or incorrect timing. Additionally, we will discuss proper maintenance techniques to keep your distributor in top shape. By following these tips, you can prevent potential problems and enjoy the smooth operation of your engine.

Common issues that may arise during or after the installation

Installing a distributor can sometimes be a complex process, and there are a few common issues that you may encounter during or after the installation. It’s important to be aware of these issues so you can address them promptly and avoid any further complications. Here are some of the most common problems:

- Misalignment of the distributor shaft:

- Timing issues:

- Electrical connections:

Troubleshooting steps for misalignment or incorrect timing

If you encounter misalignment or incorrect timing issues with your distributor installation, here are the troubleshooting steps to follow:

- Confirm timing marks:

- Adjust distributor position:

- Check for proper spark plug wire connection:

Proper maintenance of the distributor for optimal performance

Maintaining your distributor is crucial for optimal performance and longevity. Here are some important maintenance tips to follow:

- Inspect and clean the distributor cap:

- Replace the distributor rotor:

- Check the distributor shaft for wear:

- Regularly check and replace spark plug wires:

By following these troubleshooting and maintenance tips, you can ensure that your distributor installation in a 5.7 Vortec engine is successful and that you enjoy optimal performance from your vehicle. Regular maintenance and attention to detail will help prevent any potential issues and keep your engine running smoothly for years to come.

Frequently Asked Questions On How To Install A Distributor In A 5.7 Vortec

How Do You Line Up A Distributor?

To line up a distributor, follow these steps: 1. Research potential distributors in your target industry. 2. Make contact with distributors through networking, trade shows, or online platforms. 3. Prepare a compelling pitch and demonstrate the value proposition of your product or service.

4. Negotiate terms and conditions, including pricing, payment terms, and exclusivity agreements. 5. Formalize the partnership with a written agreement and establish clear communication channels for ongoing collaboration.

How Do You Set A Distributor To Top Dead Center?

To set a distributor to top dead center, follow these steps: 1. Remove the distributor cap and locate the rotor. 2. Rotate the engine clockwise until the rotor points directly at the number one cylinder (usually marked on the distributor cap).

3. Adjust the distributor by turning it until the rotor aligns with the number one cylinder’s contact point. 4. Secure the distributor cap back in place.

What Is The Firing Order On A 5.7 Vortec?

The firing order on a 5. 7 Vortec is 1-8-4-3-6-5-7-2, with the distributor rotating clockwise.

How Do You Mark A Distributor For Removal?

To mark a distributor for removal, follow these steps: 1. Access your distributor list. 2. Locate the distributor you want to remove. 3. Click on the distributor’s profile. 4. Look for the “Remove” or “Delete” option. 5. Click on the option to mark the distributor for removal.

Conclusion

Installing a distributor in a 5. 7 Vortec engine is a crucial task that requires precision and careful attention to detail. By following the step-by-step instructions outlined in this guide, you can confidently tackle this job yourself. Remember to double-check your work, ensure proper timing, and take your time during the installation process.

With practice and experience, installing a distributor will become second nature to you. Happy wrenching!